Abstract

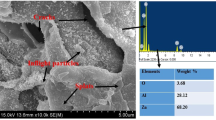

The corrosion behavior and resistance of hot-dip Al and Al−Cr coated steel sheets (SS) were investigated via scanning electron microscopy (SEM), energy dispersive X-ray spectrometry (EDX), electron probe micro analysis (EPMA), glow discharge light spectroscopy (GDLS), and X-ray diffraction patterns (XRD). The Al−Cr coated layer was composed of the following three phases. Al phase comprised the surface layer, Al13Cr2 the middle layer, and Al13Fe4 and Al5Fe2 phases the interfacial layer between the Fe substrate and the coated layer. The corrosion behavior of the Al−Cr coated layer showed different aspects compared with the Al coated layer. In the Al−Cr coated layer, Cr was observed at an intermediate layer having a band shape. From the analysis of the polarization curve, the initial corrosion current of the Al−Cr coated SS was 10 times lower than that of Al in the early stage, and the corrosion resistance was superior to that of Al. The Al coated SS formed an Al−Fe−Si IMC layer, and the coated layer was almost destroyed. Many cracks were produced, and the corroded parts were enlarged from the cracks. The upper part of the Al−Cr coated SS, an Al−Si coated layer, was corroded. In contrast, the Cr-rich intermediate layer was not destroyed. Consequently, the high corrosion resistance was attributed to the densely covered Al(OH)3 and the intermetallic compound layer of Al13Cr2. These results significantly contribute toward attaining a detailed understanding of the corrosion behavior and resistance Al−Cr coated steel sheets.

Similar content being viewed by others

References

R. Phragmen,J. Inst. Met. 77, 489 (1950).

D. O. Gittings, D. H. Rowland, and J. O. Mark,Trans. ASM 43, 587 (1951).

K. G. Coburn,Metallurgin, July, 17 (1959).

Y. S. Han, J. O. Choi, C. O. Choi, and D. G. McCartney,Met. Mater.-Int. 10, 27 (2004).

T. Yamada and H. Kawase,Testu-to-Hagane 72, 1021 (1986).

S. Higuchi, K. Asakawa, T. Ohmori, M. Hujinaga, H. Yamamoto, and A. Maruda,Steel Research 320, 8, (1986).

Y. Uchida, H. Hattori, and Y. Hirose,Nisshin Steel Tech. Rep. 59, 76 (1988).

S. Higuchi and K. Asakawa,Testu-to-Hagame 77, 266 (1991).

H. E. Townsend and J. C. Zoccola,Mater. Performance 18, 13 (1979).

S. G. Denner, R. D. Jones, and R. J. Thomas,Iron Steel Int. June, 241 (1979).

J. B. Horton,Corrosion Control by Coatings, p. 59, Science Press, Prinston, NJ (1978).

H. Yousihiro,Lead and Zinc 27, 155 (1990).

R. C. Da Silva, R. C. Sousa, O. Conde, M. F. Da Silva, and J. C. Soares,Surf. Coat. Technol. 83, 60 (1996).

S. H. Hong, B. M. Lim, W. S. Chung, and J. H. Choi,Mater. Sci. Forum 1031, 408 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, U.C., Lim, B.M., Park, I.M. et al. Corrosion behavior and resistance of hot-dip Al−Cr coated steel sheet under a salt corrosive environment. Met. Mater. Int. 11, 149–156 (2005). https://doi.org/10.1007/BF03027459

Issue Date:

DOI: https://doi.org/10.1007/BF03027459