Abstract

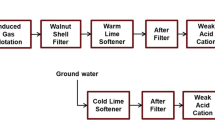

Industrial wastewater is currently a big challenge for authorities due to its environmental issues when disposed to the ecosystem. From an economic perspective and long treatment time, it is yet more reasonable to recover and reuse wastewater in industries. In this work, the wastewater from an ion exchange resin regeneration process was directly and without any further treatment reused in the wood industry for manufacturing medium density fiberboards (MDF). Comparing with the disposal criteria of international standards, the reused wastewater exhibited much higher electrical conductivity, turbidity, total dissolved solid, total suspension solid, and inorganic salt content than the permissible limits; therefore, it is categorized as hazardous material. The highly saline wastewater was added during and after synthesizing of the urea–formaldehyde (UF) resin but before mixing with the wood fibers. The Fourier transform infrared spectroscopy and differential scanning calorimetry analyses of the UF resin samples, respectively, demonstrated the high stability of the chemical structure and higher strength against decomposition for the UF resins after being treated with the wastewater. The physico–mechanical properties of MDFs prepared by reused wastewater were significantly improved whilst the formaldehyde emission of the boards was noticeably reduced (~ 17%) to the benefit of the environment.

Similar content being viewed by others

Abbreviations

- MDF:

-

Medium density fiberboard

- EC:

-

Electrical conductivity

- TU:

-

Turbidity

- TDS:

-

Total dissolved solid

- TSS:

-

Total suspension solid

- UF:

-

Urea–formaldehyde

- FTIR:

-

Fourier transform infrared spectroscopy

- DSC:

-

Differential scanning calorimetry

- IX:

-

Ion exchange

- COD:

-

Chemical oxygen demand

- UFC:

-

Urea–formaldehyde condensate

- BOD:

-

Biological oxygen demand

- KBr:

-

Potassium bromide

- MOR:

-

Modulus of rupture

- MOE:

-

Modulus of elasticity

- IB:

-

Internal bond

- TS:

-

Thickness swelling

- EPA:

-

Environmental Protection Agency

- WHO:

-

World Health Organization

- Na:

-

Sodium

- Cl:

-

Chlorine

- Mg:

-

Magnesium

- Ca:

-

Calcium

References

Akhoundi A, Nazif S (2018) Sustainability assessment of wastewater reuse alternatives using the evidential reasoning approach. J Clean Prod 195:1350–1376

Al-Barwani HH, Purnama AN (2007) Re-assessing the impact of desalination plants brine discharges on eroding beaches. Desalination 204:94–101

Amini A (2017) The sustainability of ion exchange water treatment technology. Dissertations, Doctor of Philosophy (Ph.D). University of South Florida

Ariono D, Purwasasmita M, Wenten IG (2016) Brine effluents: characteristics, environmental impacts, and their handling. J Eng Technol Sci 48:367–387

ASTM D1081-60 (1968) Standard method of test for evaluating pressure sealing properties of rubber and rubber-like materials. Am Soc Test Mater pp 1–3

Ayers RS, Westcot DW (1985) Water quality for agriculture, Food and Agriculture Organization of the United Nations Rome

Bilińska L, Gmurek M, Ledakowicz S (2017) Textile wastewater treatment by AOPs for brine reuse. Process Saf Environ 109:420–428

Brigano FA, Soucie WJ, Rak SF, Culligan International Co (1993) Reclaiming of spent brine. US Patent 5,254,257

Buscio V, Marín MJ, Crespi M, Gutiérrez-Bouzán C (2015) Reuse of textile wastewater after homogenization–decantation treatment coupled to PVDF ultrafiltration membranes. Chem Eng J 265:122–128

Crites R (1977) Process design manual for land treatment of municipal wastewater. U.S. Environmental Protection Agency pp 1–593

Dorieh A, Mahmoodi N, Mamaghani M, Pizzi A, Mohammadi Zeydi M (2018) Comparison of the properties of urea–formaldehyde resins by the use of formalin or urea formaldehyde condensates. J Adhes Sci Technol 32:2537–2551

Dorieh A, Mahmoodi NO, Mamaghani M, Pizzi A, Mohammadi Zeydi M (2019a) Effect of different acids during the synthesis of urea–formaldehyde adhesives and the mechanical properties of medium-density fiberboards bonded with them. J Appl Polym Sci 136:47256

Dorieh A, Mahmoodi NO, Mamaghani M, Pizzi A, Mohammadi Zeydi M, Moslemi A (2019b) New insight into the use of latent catalysts for the synthesis of urea formaldehyde adhesives and the mechanical properties of medium density fiberboards bonded with them. Eur Polym J 112:195–205

EN 120 (1992) Wood-based panels—determination of formaldehyde content—extraction method called the perforator method. CEN European Committee for Standardization

EN 310 (1993) Wood-based panels: determination of modulus of elasticity in bending and of bending strength. CEN European Committee for Standardization

EN 317 (1993) Particleboards and fibreboards: determination of swelling in thickness after immersion in water. CEN European Committee for Standardization

EN 319 (1993) Particleboards and fiberboards, determination of tensile strength perpendicular to plane of the board. CEN European Committee for Standardization

Gao Q, Liu C, Luo J, Li X, Chen L, Wang W, Li J (2018) Effects of resin open time and melamine addition on cold pre-pressing performance of a urea–formaldehyde resin. Eur J Wood Prod 76(4):1253–1261

Ghasemipanah K (2013) Treatment of ion-exchange resins regeneration wastewater using reverse osmosis method for reuse. Desalin Water Treat 51:5179–5183

Hashim A, Hajjaj M (2005) Impact of desalination plants fluid effluents on the integrity of seawater, with the Arabian Gulf in perspective. Desalination 182:373–393

Huang C, Peng F, Xiong L, Li HL, Chen XF, Zhao C, Chen XD (2019) Introduction of one efficient industrial system for turpentine processing wastewater reuse and treatment. Sci Total Environ 663:447–452

Huck M, Carrow RN, Duncan RR (2000) Effluent water: nightmare or dream come true. USGA Green Sect Rec 38:15–29

Iwuozor K, Gold EE (2018) Physico–chemical parameters of industrial efflents from a brewery industry in Imo State, Nigeria. Adv J Chem 1:66–78

Kabsch-Korbutowicz M, Wisniewski J, Łakomska S, Urbanowska A (2011) Application of UF, NF and ED in natural organic matter removal from ion-exchange spent regenerant brine. Desalination 280:428–431

Kanu I, Achi OK (2011) Industrial effluents and their impact on water quality of receiving rivers in Nigeria. J Appl Technol Environ Sanit 1:75–86

Khonakdar Dazmiri M, Valizadeh Kiamahalleh M, Dorieh A, Pizzi A (2019a) Effect of the initial F/U molar ratio in urea–formaldehyde resins synthesis and its influence on the performance of medium density fiberboard bonded with them. Int J Adhes Adhes 95:102440

Khonakdar Dazmiri M, Valizadeh Kiamahalleh M, Valizadeh Kiamahalleh M, Mansouri HR, Moazami V (2019b) Revealing the impacts of recycled urea–formaldehyde wastes on the physical–mechanical properties of MDF. Eur J Wood Prod 77:293–299

Kralj AK (2015) The re-usages of wastewater within industry: the positive impact of contaminants. J Clean Prod 95:124–130

Li H, Chen Y, Long J, Jiang D, Liu J, Li S, Qi J, Zhang P, Wang J, Gong J, Wu Q (2017) Simultaneous removal of thallium and chloride from a highly saline industrial wastewater using modified anion exchange resins. J Hazard Mater 333:179–185

Liu M, Wang Y, Wu Y, Wan H (2018) Hydrolysis and recycling of urea formaldehyde resin residues. J Hazard Mater 355:96–103

Markessini AC, Teukros AG (1979) Reactive catalyst for amino resins. US Patent 4,161,467

McAdam EJ, Judd SJ (2008) Biological treatment of ion-exchange brine regenerant for re-use: a review. Sep Purif Technol 62:264–272

Motter WK, Harmon DM, Hexion Inc (2012) Polymerization-enhancing composition for urea–formaldehyde resins, method of manufacture, method of use, and articles formed therefrom. US Patent 8,252,864

No BY, Harmon DM, Miller TR, Hexion Inc (2014) Storage stable amino-formaldehyde resins and applications thereof. US Patent 8,741,430

Panswad T, Anan C (1999) Impact of high chloride wastewater on an anaerobic/anoxic/aerobic process with and without inoculation of chloride acclimated seeds. Water Res 33:1165–1172

Pizzi A (1994) Advanced wood adhesives technology. CRC Press, Boca Raton, pp 1–304

Ravizky A, Nadav N (2007) Salt production by the evaporation of SWRO brine in Eilat: a success story. Desalination 205:374–379

Szesztay M, László-Hedvig Z, Kovacsovics E, Tüdős F (1993) DSC application for characterization of urea/formaldehyde condensates. Holz Roh Werkst 51:297–300

Taghiyari HR, Majidi R, Jahangiri A (2016) Adsorption of nanowollastonite on cellulose surface: effects on physical and mechanical properties of medium-density fiberboard (MDF). Cerne 22:215–222

Taghiyari HR, Moradiyan A, Farazi A (2013) Effect of nanosilver on the rate of heat transfer to the core of the medium density fiberboard mat. Int J Bioinorg Hybrid Nanomater 2:303–308

Turek M (2003) Seawater desalination and salt production in a hybrid membrane-thermal process. Desalination 153:173–177

Uraki Y, Nemoto J, Yanaga K, Koizumi A, Hirai T (2005) Preparation of board-like moldings from composites of isolated lignins and waste paper II: effect of inorganic salt addition on board performance and evaluation of practical use of MDF. J Wood Sci 51:589–594

USEPA (2012) Guideline for water reuse. Office of wastewater management, office of water. United States Environmental Protection Agency, Washington (DC)

Venzke CD, Giacobbo A, Ferreira JZ, Bernardes AM, Rodrigues MA (2018) Increasing water recovery rate of membrane hybrid process on the petrochemical wastewater treatment. Process Saf Environ 117:152–158

WHO, World Health Organization (1989) Health guidelines for the use of wastewater in agriculture and aquaculture: report of a WHO scientific group [meeting held in Geneva from 18 to 23 November 1987]

WHO, World Health Organization (2006) Guidelines for the safe use of wastewater, excreta and greywater, World Health Organization

WHO, World Health Organization (2017) Potable reuse: guidance for producing safe drinking-water

Younesi-Kordkheili H, Kazemi-Najafi S, Eshkiki RB, Pizzi A (2015) Improving urea formaldehyde resin properties by glyoxalated soda bagasse lignin. Eur J Wood Prod 73(1):77–85

Zorba T, Papadopoulou E, Hatjiissaak A, Paraskevopoulos K, Chrissafis K (2008) Urea–formaldehyde resins characterized by thermal analysis and FTIR method. J Therm Anal Calorim 92:29–33

Acknowledgements

This research was supported by Mr. Ali Saeedi, the head of Arian Saeed Industrial Group (ASIG), and the authors are thankful for his invaluable support. Further, special gratitude to all employees in Chassbsaz company for their support in this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Valizadeh Kiamahalleh, M., Khonakdar Dazmiri, M., Valizadeh Kiamahalleh, M. et al. Direct reuse at industrial level of ion-exchange resin regeneration wastewater in MDF manufacturing. Eur. J. Wood Prod. 78, 523–531 (2020). https://doi.org/10.1007/s00107-020-01513-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01513-0