Abstract

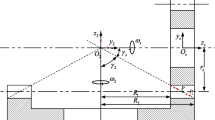

In order to solve some common problems of CNC-machined spiral bevel gears such as small cutting strip width and poor surface quality, while milled by the ball-end, a machining method of face milling using a disk cutter with a concave end is presented. The research theories are based on the foundation of spiral bevel gears’ geometry structure. Firstly, a bigger diameter disk cutter with a concave end is selected. Then, change the setting order of cutter orientation angles. The functions of cutter tilt and yaw angle are separated, and tooth surfaces machined with big cutting strip width and no bottom land gouge can be expected. Since the cutter yaw angle, determined firstly by cutting contact point, positions in the tooth surface machine, the bottom land gouge interference can be avoided effectively. Then, the tilt angles of the gear pair, both side tooth surfaces, are determined by the theory of sculptured surfaces machined by the flat-end cutter, respectively. As a result, the improved cutting strip width and machining efficiency can be realized. Finally, feasibility of this method is verified through machining experiment and measurement of a spiral bevel gear pair.

Similar content being viewed by others

References

Suh SH, Lee J (1998) Multi-axis machining with additional-axis NC system. Int J Adv Manuf Technol 14:865–875

Suh SH, Jih WS, Hong HD, Chung DH (2001) Sculptured surface machining of spiral bevel gears with CNC milling. Int J Mach Tool Manuf 41:833–850

Ling WF (2008) The study of spiral bevel gears new machining methods and crucial technology. Dissertation, Beijing Jiaotong University

Kawasaki K, Tsuji I, Abe Y, Gunbara H (2011) Manufacturing method of large-sized spiral bevel gears in cyclo-palloid system using multi-axis control and multi-tasking machine tool. JSME Ser C 77:728–736

Vichers GW, Quan KW (1989) Ball-mills versus end-mills for curved surface machining. J Eng Ind 111:22–26

Wang XC, Wu XT, Li YB (1992) Curvature catering—a new concept for machining sculptured surfaces. J Xi’an Jiaotong Univ 26:51–110

Choi BK, Park JW, Jun CS (1993) Cutter-location data optimization in 5-axis surface machining. CAD 25:377–386

Rao NV, Bedi S, Buchal R (1996) Implementation of the principal axis method for machining sculptured surfaces. Int J Adv Manuf Technol 11:249–257

Warkentin A, Ismail F, Bedi S (1998) Intersection approach to multi-point machining of sculptured surfaces. CAGD 15:567–584

Fan WG, Wang XC, Jiang H, Cai YL (2010) Multi-point tool positioning strategy for five-axis machining of open sculptured concave surfaces. J Xi’an Jiaotong Univ 44:69–73

Fan WG, Li JY, Huang ZH, Ma LM (2012) Application of multi-point contact machining to convex sculptured surface. J Xi’an Jiaotong Univ 46(3):53–63

Li TX, Deng XZ, Li JB, Yang JJ (2011) Automatic feedback correction and deviation analysis for tooth surface of spiral bevel gear and hypoid gear. J Aerosp Power 26:1194–1200

Litvin FL, Chen NX, Chen JS (1995) Computerized determination of curvature relations and contact ellipse for conjugate surfaces. Comput Method Appl M 125:151–170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, Xz., Li, Gg., Wei, By. et al. Face-milling spiral bevel gear tooth surfaces by application of 5-axis CNC machine tool. Int J Adv Manuf Technol 71, 1049–1057 (2014). https://doi.org/10.1007/s00170-013-5499-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5499-3