Abstract

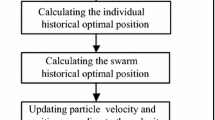

Automation of engineering procedures for the development of new manufacturing processes is of great importance in modern competitive conditions. For example, metalworking companies would greatly benefit from the development of methods for automatic generation, testing and optimization of part programs for machining operations. Indeed, the generation of part programs—even by using CAM software—does still require strong human intervention and it is basically a best guess approach with minimum optimization. Moreover, further refinement and correction of the part program on the machine tool is often necessary. Machining operations are generally based on a large number of parameters and therefore optimization strategies should be able to deal with high-dimensional spaces and disjoint domains. In this paper, two swarm intelligence optimization algorithms—particle swarm optimization (PSO) and artificial bee colony (ABC)—have been applied for optimizating the part program of a complex turning part. The optimizers were implemented in a framework for automatic part program generation, realistic simulation, and feasibility analysis. The results evidenced that both approaches were capable of optimizing efficiently the part program, and that the optimization time of the PSO approach on modern computers may be suitable for application in production.

Similar content being viewed by others

References

Altintas Y, Brecher C, Weck M, Witt S (2005) Virtual machine tool. CIRP Annals Manuf Technol 54(2):115. doi:10.1016/S0007-8506(07)60022-5

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations and CNC Design. Cambridge University Press

Altintas Y, Kersting P, Biermann D, Budak E, Denkena B, Lazoglu I (2014) Virtual process systems for part machining operations. CIRP Annals - Manuf Technol. doi:10.1016/j.cirp.2014.05.007

Bouzakis KD, Aichouh P, Efstathiou K (2003) Determination of the chip geometry, cutting force and roughness in free form surfaces finishing milling, with ball end tools. Int J Mach Tools Manuf 43(5):499. doi:10.1016/S0890-6955(02)00265-1

Bouzakis KD, Friderikos O, Tsiafis I (2008) FEM-supported simulation of chip formation and flow in gear hobbing of spur and helical gears. CIRP J Manuf Scie Technol 1(1):18. doi:10.1016/j.cirpj.2008.06.004

Sortino M, Totis G, Kuljanić E, Cukor G (2009) Simulation of cutting forces and cutting conditions in complex turning operations. In: Proceedings of the 12th international scientific conference on production engineering - CIM2009, pp 201–207

Sortino M, Belfio S, Totis G (2014) An innovative approach for automatic generation, verification and optimization of part programs in turning. J Manuf Syst. doi:10.1016/j.jmsy.2014.03.002

Chen MC, Tsai DM (1996) A simulated annealing approach for optimization of multi-pass turning operations. Int J Prod Res 34(10):2803. doi:10.1080/00207549608905060

Su CT, Chen MC (1999) Computer-aided optimization of multi-pass turning operations for continuous forms on CNC lathes. IIE Trans 31(7):583. doi:10.1023/A:1007678615643

Amiolemhen P, Ibhadode A (2004) Application of genetic algorithms determination of the optimal machining parameters in the conversion of a cylindrical bar stock into a continuous finished profile. Int J Mach Tools Manuf 44(12–13):1403. doi:10.1016/j.ijmachtools.2004.02.001

Chen MC (2004) Optimizing machining economics models of turning operations using the scatter search approach. Int J Prod Res 42(13):2611. doi:10.1080/00207540410001666251

Saravanan RSRS, Asokan P, Vijayakumar K, Prabhaharan G (2005) Optimization of cutting conditions during continuous finished profile machining using non-traditional techniques. Int J Adv Manuf Technol 26(1–2):30. doi:10.1007/s00170-003-1938-x

Satishkumar S, Asokan P, Kumanan S (2006) Optimization of depth of cut in multi-pass turning using nontraditional optimization techniques. Int J Adv Manuf Technol 29(3–4):230. doi:10.1007/s00170-005-2526-z

Sankar R, Asokan P, Saravanan R, Kumanan S, Prabhaharan G (2007) Selection of machining parameters for constrained machining problem using evolutionary computation. Int J Adv Manuf Technol 32(9–10):892. doi:10.1007/s00170-006-0420-y

Lie Tang RGL, Balakrishnan SN (2008) Parallel turning process parameter optimization based on a novel heuristic approach. J Manuf Sci Eng 130(3):031002. doi:10.1115/1.2823077

Bharathi Raja S, Baskar N (2010) Optimization techniques for machining operations: a retrospective research based on various mathematical models. Int J Adv Manuf Technol 48(9–12):1075. doi:10.1007/s00170-009-2351-x

Costa A, Celano G, Fichera S (2011) Optimization of multi-pass turning economies through a hybrid particle swarm optimization technique. Int J Adv Manuf Technol 53(5–8):421. doi:10.1007/s00170-010-2861-6

Wang YC, Chiu YC, Hung YP (2011) Optimization of multi-task turning operations under minimal tool waste consideration. Robot Comput-Integr Manuf 27(4):674. doi:10.1016/j.rcim.2010.12.003

Yildiz AR (2012) A comparative study of population-based optimization algorithms for turning operations. Inf Sci 210:81. doi:10.1016/j.ins.2012.03.005

Yildiz AR (2013) Hybrid Taguchi-differential evolution algorithm for optimization of multi-pass turning operations. Appl Soft Comput 13(3):1433. doi:10.1016/j.asoc.2012.01.012

Ganesan H, Mohankumar G (2013) Optimization of machining techniques in CNC turning centre using genetic algorithm. Arabian J Sci Eng 38(6):1529. doi:10.1007/s13369-013-0539-8

Yusup N, Zain AM, Hashim SZM (2012) Evolutionary techniques in optimizing machining parameters: review and recent applications (2007 - 2011). Expert Syst Appl 39(10):9909. doi:10.1016/j.eswa.2012.02.109

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: IEEE international conference on neural networks, 1995. Proceedings, vol 4, pp 1942–1948. doi:10.1109/ICNN.1995.488968

Kennedy J, Kennedy J, Eberhart R, Shi Y (2001) Swarm intelligence. Evolutionary computation series. Morgan Kaufmann Publishers

Karaboga D (2005) An idea based on honey bee swarm for numerical optimization. Tech. Rep. TR06. Erciyes University

Karaboga D, Akay B, Ozturk C (2007) In: Torra V, Narukawa Y, Yoshida Y (eds) Modeling decisions for artificial intelligence, lecture notes in computer science, vol 4617. Springer Berlin Heidelberg, pp 318–329. doi:10.1007/978-3-540-73729-2_30

Childs T, Maekawa K Metal machining: theory and applications. Referex Engineering (Arnold, 2000)

Wong TT, Luk WS, Heng PA (1997) Sampling with Hammersley and Halton points. J Graph Tools 2(2):9. doi:10.1080/10867651.1997.10487471

Van Den Bergh F (2002) An analysis of particle swarm optimizers. Ph.D. thesis, University of Pretoria, Pretoria, South Africa. AAI0804353

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sortino, M., Belfio, S., Totis, G. et al. An investigation on swarm intelligence methods for the optimization of complex part programs in CNC turning. Int J Adv Manuf Technol 80, 657–672 (2015). https://doi.org/10.1007/s00170-015-7011-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7011-8