Abstract

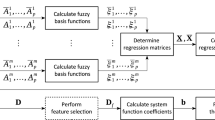

There are several methods of monitoring metal cutting processes. In this study, the combination of various methods in order to define an overall “cutting state” of a turning process is discussed along with an application to use these methods for adaptive fuzzy feed rate and cutting speed optimising control. For this purpose, different methods of monitoring individual cutting phenomena such as chip length and vibration level are aggregated and the combination of this information is considered to be the cutting state of the process. Expert data has been collected from a series of experiments concerning the apparent state of these phenomena as well as required control action. An adaptive optimizing fuzzy controller has been designed based on the concept of the cutting state and collected expert rules. The automatically classified cutting state as well as the control action based on this state is compared to expert data. There are notable differences which are analysed and solutions and further research are suggested based on the points requiring further improvement.

Similar content being viewed by others

References

Albertelli P, Musletti S, Leonesio M, Bianchi G, Monno M (2012) Spindle speed variation in turning: technological effectiveness and applicability to real industrial cases. Int J Adv Manuf Technol 62(1–4):59–67

Aliustaoglu C, Ertunc HM, Ocak H (2009) Tool wear condition monitoring using a sensor fusion model based on fuzzy inference system. Mech Syst Signal Process 23(2):539–546

Balazinski M, Czogala E, Jemielniak K, Leski J (2002) Tool condition monitoring using artificial intelligence methods. Eng Appl Artif Intell 15(1):73–80

Brezak D, Majetic D, Udiljak T, Kasac J (2012) Tool wear estimation using an analytic fuzzy classifier and support vector machines. J Intell Manuf 23(3):797–809

Hynynen KM, Ratava J, Lindh T, Rikkonen M, Ryynänen V, Lohtander M, Varis J (2014) Chatter detection in turning processes using coherence of acceleration and audio signals. J Manuf Sci Eng 136(4):044,503

Laakso S, Peltokorpi J, Ratava J, Lohtander M, Varis J (2013) Graph-based analysis of metal cutting parameters. In: Advances in sustainable and competitive manufacturing systems. Springer, pp 627–636

Liao Y, Young Y (1996) A new on-line spindle speed regulation strategy for chatter control. Int J Mach Tools Manuf 36(5):651–660

Mamdani EH, Assilian S (1975) An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud 7(1):1–13

Masory O, Koren Y, Weill R (1980) Adaptive control system for turning. CIRP Ann Manuf Technol 29(1):281–284

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Ratava J, Rikkonen M, Ryynänen V, Leppänen J, Lindh T, Varis J, Sihvo I (2011) An adaptive fuzzy control system to maximize rough turning productivity and avoid the onset of instability. Int J Adv Manuf Technol 53(1–4):71–79

Ratava J, Luukka P, Lohtander M, Varis J (2014) A sugeno-type fuzzy expert system for rough turning. In: Key engineering materials, vol 572. Trans Tech Publ, pp 597–600

Ratava J, Lindh T, Lohtander M, Varis J (2015) Comparison of methods for chipping quality estimation in turning. Int J Adv Manuf Technol 79(9–12):1569–1579

Ratava J, Lohtander M, Varis J (2016) Adaptive fuzzy optimizing control for metal turning. In: Proceedings of the 26th international conference on flexible automation and intelligent machining, p B1.1

Ratava J, Lohtander M, Varis J (2016) Modelling cutting instability in rough turning 34crnimo6 steel. International Journal of Operational Research 25(4):518–531

Ratava J, Lohtander M, Varis J (2017) Tool condition monitoring in interrupted cutting with acceleration sensors. Robot Comput Integr Manuf 47(2017):70–75

Stryczek R, Orawczak K (2013) A fuzzy control strategy in the turning process. Advances in Manufacturing Science and Technology 37(1):79–88

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern SMC-15(1):116–132

Tangjitsitcharoen S, Lohasiriwat H (2016) Monitoring of cutting states in cnc turning by using wavelet transform. In: Proceedings of the 26th international conference on flexible automation and intelligent machining, p C3.4

Tangjitsitcharoen S, Moriwaki T (2007) Intelligent identification of turning process based on pattern recognition of cutting states. J Mater Process Technol 192:491–496

Tarng Y, Hseih Y, Li T (1996) Automatic selection of spindle speed for suppression of regenerative chatter in turning. Int J Adv Manuf Technol 11(1):12–17

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Zadeh LA (1975) The concept of a linguistic variable and its application to approximate reasoning—i. Inf Sci 8(3):199–249

Acknowledgements

This study is an expanded version of results presented in the 26th International Conference on Flexible Automation and Intelligent Machining [14].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

The experimental part of this study has been funded by Tekes, Finnish Funding Agency for Innovation (“Vmax” project).

Rights and permissions

About this article

Cite this article

Ratava, J., Lohtander, M. Fuzzy feed rate and cutting speed optimization in turning. Int J Adv Manuf Technol 99, 2081–2092 (2018). https://doi.org/10.1007/s00170-018-1845-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1845-9