Abstract

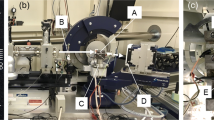

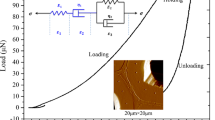

This research examines the effect of thermal modification on the mechanical properties of the soft wood cell wall in order to clarify the relationship between the micro-level behavior (cellulose microfibrils) and macro-level behavior (bulk wood). The thermal modification of three stages at two different temperatures was conducted on the specimens. Then, the synchrotron radiation XRD under tensile loading in the axial direction of thermally modified bulk wood was performed. Simultaneously, the lattice strain of cellulose in the S1 and S3 layers and the strain of bulk wood were obtained. As a result of the tensile test, for unmodified specimens, the load–strain relationship of the cellulose microfibrils in the S1 and S3 layers showed linear behavior similar to bulk wood. In contrast, for thermally modified specimens, it was found that the load–strain relationship of the cellulose microfibrils in the S1 and S3 layers was not linear. The effects of thermal modification on tensile properties of bulk wood differed from that of the cellulose microfibrils in the S1 and S3 layers. Furthermore, when compared with the results of the cellulose microfibrils in the S2 layer, the effect of thermal modification was different between the cell wall layers. The reason for this was suggested by the orientation angle and linearity of the cellulose microfibrils.

Similar content being viewed by others

Abbreviations

- d :

-

Lattice spacing of the cellulose (004) plane (Å)

- MC:

-

Moisture content at the moment of testing (%)

- MFA:

-

Microfibril angle (degree)

- ML:

-

Mass loss ratio (%)

- n :

-

Number of specimens

- P B :

-

Tensile load acting on bulk wood (specimens) (N)

- P Bmax :

-

Maximum tensile load acting on bulk wood (specimens) (N)

- P C :

-

Tensile load acting on cellulose microfibrils (N)

- P Cmax :

-

Maximum tensile load acting on cellulose microfibrils (the load associated with the maximum cellulose strain) (N)

- ε B :

-

Strain of bulk wood obtained by strain gauge

- ε Bmax :

-

Maximum strain of bulk wood obtained by strain gauge

- ε C :

-

Strain of cellulose microfibrils obtained by XRD measurement

- ε Cmax :

-

Maximum strain of cellulose microfibrils obtained by XRD measurement

- θ :

-

Angle formed between the scattered X-rays and crystal face of cellulose microfibrils (degree)

- ρ um :

-

Unmodified density (kg m−3)

- ρ m :

-

Modified density at the moment of testing (kg m−3)

References

Abe K, Yamamoto H (2005) Mechanical interaction between cellulose microfibril and matrix substance in wood cell determined by X-ray diffraction. J Wood Sci 51:334–338. https://doi.org/10.1007/s10086-004-0667-6

Cave ID (1966) Theory of X-ray measurement of microfibril angle in wood. Forest Prod J 16:37–42. https://doi.org/10.1007/BF00705881

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Froidevaux J, Volkmer T, Ganne-Chedeville C, Gril J, Navi P (2012) Viscoelastic behavior of aged and non-aged spruce wood in the radial direction. Wood Mat Sci Eng 7(1):1–12. https://doi.org/10.1080/17480272.2011.629735

Hirashima Y, Sugihara M, Sasaki Y, Ando K, Yamasaki M (2004) Strength properties of aged wood I: tensile strength properties of aged keyaki and akamatsu woods. Mokuzai Gakkaishi 50:301–309 (in Japanese)

Imaeda K, Yamasaki M, Kojima E, Lee CG, Sugimoto T, Sasaki Y (2020) Energetic investigation of aging effect on mechanical behavior in wood by means of XRD measurement. Int J Arch Heritage. https://doi.org/10.1080/15583058.2020.1743793(published Online 14 Apr 2020)

Kohara J (1952) Studies on the durability of wood I: mechanical properties of old timbers. (Horyuji temple construction timbers Chamaecyparis obtusa ENDLICHER). Sci Rep Saikyo Univ 2:116–131 (in Japanese)

Kojima E, Yamasaki M, Imaeda K, Lee CG, Sugimoto T, Sasaki Y (2020) Effects of heat treatment on the mechanical properties of the wood cell wall: behavior of S2 cellulose microfibrils under tensile loading. J Mater Sci 55(12):5038–5047. https://doi.org/10.1007/s10853-020-04346-7

Kránitz K, Sonderegger W, Bues CT, Niemz P (2016) Effects of aging on wood: a literature review. Wood Sci Technol 50:7–22. https://doi.org/10.1007/s00226-015-0766-0

Lee CG, Yamasaki M, Sugimoto T, Sasaki Y (2019a) Synchrotron X-ray measurement of cellulose in wood cell wall layers of Pinus densiflora in the transmission and reflectance modes. Part1: results without loading. Holzforschung 73(7):613–619. https://doi.org/10.1515/hf-2018-0120

Lee CG, Yamasaki M, Kojima E, Sugimoto T, Sasaki Y (2019b) Synchrotron X-ray measurements of cellulose in wood cell wall layers of Pinus densiflora in the transmission and reflectance modes Part 2: results with axial loading. Holzforschung. https://doi.org/10.1515/hf-2019-0222(published Online 28 Oct 2020)

Matsuo M, Yokoyama M, Umemura K, Sugiyama J, Kawai S, Girl J, Kubodera S, Mitsutani R, Ozaki H, Sakamoto M, Imamura M (2011) Aging of wood: analysis of color changes during natural aging and heat treatment. Holzforschung 65:361–368. https://doi.org/10.1515/hf.2011.040

Meylan BA (1967) Measurement of microfibril angle by X-ray diffraction. For Prod J 17:51–58

Mitchell PH (1988) Irreversible property changes of small loblolly pine specimens heated in air, nitrogen, or oxygen. Wood Fib Sci 20(3):320–355

Montero C, Clair B, Alméras T, Lee A, Gril J (2012) Relationship between wood elastic strain under bending and cellulose crystal strain. Compos Sci Technol 72:175–181. https://doi.org/10.1016/j.compscitech.2011.10.014

Nakai T, Yamamoto H, Nakao T (2005) The relationship between macroscopic strain and crystal lattice strain in wood under uniaxial stress in the fiber direction. J Wood Sci 51:193–194. https://doi.org/10.1007/s10086-005-0697-8

Nakai T, Yamamoto H, Nakao T, Hamatake M (2006) Mechanical behavior of the crystal lattice of natural cellulose in wood under repeated uniaxial tension stress in the fiber wood. Wood Sci Technol 40:683–695. https://doi.org/10.1007/s00226-006-0095-4

Obataya E (2017) Effects of natural and artificial ageing on the physical and acoustic properties of wood in musical instruments. J Cult Heritage 27:63–69. https://doi.org/10.1016/j.culher.2016.02.011

Peura M, Grotkopp I, Lemke H, Vikkula A, Laine J, Müller M, Serimaa R (2006) Negative poisson ratio crystalline cellulose in kraft cooked Norway spruce. Biomacromol 7:1521–1528. https://doi.org/10.1021/bm050722o

Peura M, Kölln K, Grotkopp I, Saranpää P, Müller M, Serimaa R (2007) The effect of axial strain on crystalline cellulose in Norway spruce. Wood Sci Technol 41:565–583. https://doi.org/10.1007/s00226-007-0141-x

Richard EM (1967) Cell wall mechanics of tracheids. Filament Winding Angles. McKay Press Inc, Midland, Michigan, USA, pp 164–166

Sandberg D, Haller P, Navi P (2013) Thermo-hydro and thermo-hydro-mechanical wood processing: an opportunity for future environmentally friendly wood products. Wood Mat Sci Eng 8:64–88. https://doi.org/10.1080/17480272.2012.751935

Shafizadeh F, Bradbury AGW (1979) Thermal degradation of cellulose in air and nitrogen at low temperatures. J Appl Poly Sci 23:1431–1442. https://doi.org/10.1002/app.1979.070230513

Sobue N, Hirai N, Asano I (1971) On the measurement of strain distribution in wood under the axial tension force by X-ray diffraction. J Soc Mater Sci Jpn 20:1188–1193 (in Japanese)

Tanaka F, Takaki T, Okamura K, Koshima T (1980) Orientation distribution of cellulose crystallites in woody plants. Part I: pole-figures and orientation functions of cellulose crystallites in opposite wood of Pinus densiflora. Wood Res Bull Wood Res Inst Kyoto Univ 66:17–22

Werner K, Pommer L, Broström M (2014) Thermal decomposition of hemicellulose. J Anal Appl Pyrolysis 110:130–137. https://doi.org/10.1016/j.jaap.2014.08.013

Zabler S, Paris O, Burgert I, Fratzl P (2010) Moisture changes in the plant cell wall force cellulose crystallites to deform. J Struct Biol 171:133–141. https://doi.org/10.1016/j.jsb.2010.04.013

Zeniya N, Obataya E, Endo K, Matsuo M (2018) Application of time–temperature–humidity superposition to the mass loss of wood through hygrothermally accelerated ageing at 95–140 °C and different relative humidity levels. SN Appl Sci 1:3. https://doi.org/10.1007/s42452-018-0009-8

Acknowledgement

This work was supported in part by the Photon-Beam Platform Project of the Ministry of Education, Culture, Sports, Science and Technology. The XRD experiments were conducted at the BL8S1 of Aichi Synchrotron Radiation Center, Aichi Science & Technology Foundation, Aichi, Japan (Approval No. 2016G1012). This work was supported by Grant-in-Aid for Scientific Research (C) Number 17K06638.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kojima, E., Yamasaki, M., Imaeda, K. et al. XRD investigation of mechanical properties of cellulose microfibrils in S1 and S3 layers of thermally modified wood under tensile loading. Wood Sci Technol 55, 955–969 (2021). https://doi.org/10.1007/s00226-021-01263-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-021-01263-z