Abstract

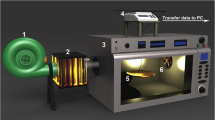

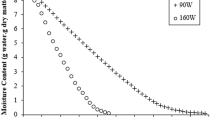

Drying behavior and kinetics of apricot halves were investigated in a microwave-hot air domestic hybrid oven at 120, 150 and 180 W microwave power and 50, 60 and 70 °C air temperature. Drying operation was finished when the moisture content reached to 25% (wet basis) from 77% (w.b). Increase in microwave power and air temperature increased drying rates and reduced drying time. Only falling rate period was observed in drying of apricot halves in hybrid oven. Eleven mathematical models were used for describing the drying kinetics of apricots. Modified logistic model gave the best fitting to the experimental data. The model has never been used to explain drying behavior of any kind of food materials up to now. Fick’s second law was used for determination of both effective moisture diffusivity and thermal diffusivity values. Activation energy values of dried apricots were calculated from Arrhenius equation. Those that obtained from effective moisture diffusivity, thermal diffusivity and drying rate constant values ranged from 31.10 to 39.4 kJ/mol, 29.56 to 35.19 kJ/mol, and 26.02 to 32.36 kJ/mol, respectively.

Similar content being viewed by others

Abbreviations

- a, b, c, g, h, l, n :

-

Equation constants

- α :

-

Thermal diffusivity (m2/s)

- α 0 :

-

Pre-exponential constant of Arrhenius equation (m2/s)

- AOAC:

-

Association of official analytical chemists

- DR:

-

Drying rate (g water/g dry matter.min)

- D eff :

-

Effective moisture diffusivity (m2/s)

- D 0 :

-

Pre-exponential constant of Arrhenius equation (m2/s)

- E a :

-

Activation energy (kJ/mol)

- FAO:

-

Food and Agriculture Organization of the United Nations

- k :

-

Drying rate constant (1/min)

- k 0 :

-

Pre-exponential constant of Arrhenius equation (1/min)

- L:

-

Half thickness of sample (m)

- M 0 :

-

Initial moisture content (g water/g dry matter)

- M e :

-

Final moisture content (g water/g dry matter)

- M t :

-

Moisture content at any time (g water/g dry matter)

- MR:

-

Moisture ratio

- MR exp,i :

-

Experimental moisture ratio

- MR pre,i :

-

Predicted moisture ratio

- N:

-

Number of experimental data

- R:

-

Universal gas constant (kJ/mol K)

- R:

-

Function

- R 2 :

-

Correlation coefficient

- RMSE :

-

Root mean square error

- t :

-

Drying time (min)

- T :

-

Temperature of slab at any time (°C)

- T 0 :

-

Initial temperature of slab (°C)

- T s :

-

Temperature of drying chamber (°C)

- TR:

-

Dimensionless temperature ratio

- x :

-

Independent variable

- χ2 :

-

Reduced Chi square

- W R , w :

-

Uncertainty

- w.b:

-

Wet basis

- z:

-

Number of parameters in the model

References

FAO (2013) Food and Agriculture Organization of the United Nations. Statistical Database. http://faostat3.fao.org/browse/Q/QC/E. Accessed 12 Nov 2015

Igual M, García-Martínez E, Martín-Esparza ME, Martínez-Navarrete N (2012) Effect of processing on the drying kinetics and functional value of dried apricot. Food Res Int 47:284–290

Dai J, Rao J, Wang D, Xie L, Xiao H, Liu Y, Gao Z (2015) Process-based drying temperature and humidity integration control enhancement drying kinetics of apricot halves. Dry Technol 33:365–376

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Ahrné LM, Pereira N, Staack N, Floberg P (2007) Microwave convective drying of plant foods at constant and variable microwave power. Dry Technol 25:1149–1153

Askari GR, Emam-Djomeh Z, Mousavi SM (2009) An investigation of the effects of drying methods and conditions on drying characteristics and quality attributes of agricultural products during hot air and hot air/microwave-assisted dehydration. Dry Technol 27:831–841

Andrés A, Bilbao C, Fito P (2004) Drying kinetics of apple cylinders under combined hot air-microwave dehydration. J Food Eng 63:71–78

Karaaslan SN, Tunçer İK (2008) Development of a drying model for combined microwave-fan-assisted convection drying of spinach. Biosyst Eng 100:44–52

Alibas I (2006) Characteristics of chard leaves during microwave, convective, and combined microwave-convective drying. Dry Technol 24:1425–1435

Alibas I (2007) Microwave, air and combined microwave-air drying parameters of pumpkin slices. Lebensm Wiss Technol 40:1445–1451

Toğrul IT, Pehlivan D (2003) Modelling of drying of single apricot. J Food Eng 58:23–32

Darvishi H, Asl AR, Asghari A, Azadbakht M, Najafi G, Khodaei J (2014) Study of drying kinetics of pepper. J Saudi Soc Agric Sci 13:130–138

Zwietering MH, Jongenburger I, Rombouts FM, Van‘t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microb 56:1875–1881

Çelekli A, Bozkurt H (2013) Predictive modeling of an azo metal complex dye sorption by pumpkin husk. Environ Sci Pollut 20:7355–7366

AOAC (1995) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Arlington

Parlak N (2015) Fluidized bed drying characteristics and modeling of ginger (Zingiberofficinale) slices. Heat Mass Transf 51:1085–1095

Arslan D, Özcan MM, Mengeş OH (2010) Evaluation of drying methods with respect to drying parameters, some nutritional and colour characteristics of peppermint (Mentha x piperita L.). Energy Conver Manag 51:2769–2775

Zarein M, Samadi SH, Ghobadian B (2015) Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J Saudi Soc Agr Sci 14:41–47

Doymaz I (2016) Drying kinetics, rehydration and colour characteristics of convective hot-air drying of carrot slices. Heat Mass Transf. doi:10.1007/s00231-016-1791-8

Soysal Y, Öztekin S, Eren Ö (2006) Microwave drying of parsley: modelling, kinetics, and energy aspects. Biosyst Eng 93:403–413

Doymaz I (2011) Drying of thyme (Thymus vulgaris L.) and selection of a suitable thin-layer drying model. J Food Process Preserv 35:458–465

İsmail O, Kantürk Figen A, Pişkin S (2015) Effects of open-air sun drying and pre-treatment on drying characteristics of purslane (Portulaca oleracea L.). Heat Mass Transf 51:807–813

Sharma GP, Verma RC, Pathare P (2005) Mathematical modeling of infrared radiation thin layer drying of onion slices. J Food Eng 71:282–286

Kaleta A, Górnicki K (2010) Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int J Food Sci Technol 45:891–898

Crank J (1975) The mathematics of diffusion. Clarendon Press, Oxford

Akpınar EK, Bicer Y, Midilli A (2003) Modelling and experimental study on drying of apple slices in a convective cyclone dryer. J Food Process Eng 26:515–541

Holman JP (2012) Analysis of experimental data. In: Holman JP (ed) Experimental methods for engineers. McGraw Hill, New York

Erbay Z, Icier F (2010) Thin-layer drying behaviors of olive leaves (Olea Europaea L.). J Food Process Eng 33:287–308

Gunhan T, Demir V, Hancioglu E, Hepbasli A (2005) Mathematical modeling of drying of bay leaves. Energ Convers Manag 46:1667–1679

Midilli A (2001) Determination of pistachio drying behaviour and conditions in a solar drying system. Int J Energy Res 25:715–725

Varith J, Dijkanarukkul P, Achariyaviriya A, Achariyaviriya S (2007) Combined microwave-hot air drying of peeled longan. J Food Eng 81:459–468

Beigi M (2016) Hot air drying of apple slices: dehydration characteristics and quality assessments. Heat Mass Transf 52:1435–1442

Torki-Harchegani M, Ghasemi-Varnamkhasti M, Ghanbarian D, Sadeghi M, Tohidi M (2016) Dehydration characteristics and mathematical modeling of lemon slices drying undergoing oven treatment. Heat Mass Transf 52:281–289

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44:71–78

Özgen F (2015) Experimental investigation of drying characteristics of cornelian cherry fruits. Heat Mass Transf 51:343–352

Mirzaee E, Rafiee S, Keyhani A (2010) Evaluation and selection of thin-layer models for drying kinetics of apricot (cv. NASIRY). Agric Eng Int CIGR J 12:111–116

Çağlar A, Toğrul Türk İ, Toğrul H (2009) Moisture and thermal diffusivity of seedless grape under infrared drying. Food Bioprod Process 87:292–300

Kostaropulos AE, Saravacos GD (1997) Thermal diffusivity of granular and porous foods at low moisture content. J Food Eng 33:101–109

Mariani VC, de Lima AGB, Coelho LS (2008) Apparent thermal diffusivity estimation of the banana during drying using inverse method. J Food Eng 85:569–579

Singh KK, Goswami TK (2000) Thermal properties of cumin seeds. J Food Eng 45:181–187

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuff. Dry Technol 14:2225–2253

Demiray E, Tulek Y (2012) Thin-layer drying of tomato (Lycopersicum esculentum Mill. Cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Transf 48:841–847

Mirzaee E, Rafiee S, Keyhani A, Emam-Djomeh Z (2009) Determining of moisture diffusivity and activation energy in drying of apricots. Res Agric Eng 55:114–120

Aghbashlo M, Kianmehr MH, Hassan-Beygi SY (2010) Drying and rehydration characteristics of sour cherry (Prunus cerasus L.). J Food Process Pres 34:351–365

Özbek B, Dadali G (2007) Thin-layer drying characteristics and modeling of mint leaves undergoing microwave treatment. J Food Eng 83:541–549

Acknowledgements

Ministry of Science, Industry and Technology of Republic of Turkey and Arçelik A.Ş. are acknowledged for the support of the study. E. Horuz also acknowledges TUBITAK-BIDEB (The scientific and Technological Research Council of Turkey) for the national Ph.D. study scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horuz, E., Bozkurt, H., Karataş, H. et al. Drying kinetics of apricot halves in a microwave-hot air hybrid oven. Heat Mass Transfer 53, 2117–2127 (2017). https://doi.org/10.1007/s00231-017-1973-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1973-z