Abstract

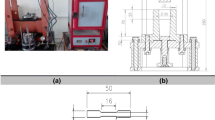

The estimation for interfacial heat transfer coefficient (IHTC) between casting and mold is paramount to predict solidification phenomena. In this study, three hydraulic pressures of 30, 60, and 90 MPa were applied to indirectly squeeze cast magnesium alloy AZ91 in a P20 steel mold with five casting section thicknesses of 2, 4, 8, 12, and 20 mm, named steps 1, 2, 3, 4 and 5, by using a 75-ton hydraulic press machine. For comparison, the AZ91 alloy was also cast without the applied pressure (0 MPa). K-type thermocouples were utilized to measure temperatures simultaneously on the casting surface and at three different depths from the mold surface inward. Based on the temperature measurements, the IHTCs at the five steps were calculated by the inverse method. Despite of the differences in their peak values, the IHTC variation for the three applied pressures at the five steps during the squeeze casting process was similar to that of 0 MPa, in which the IHTC values abruptly rose to an apex first, and then declined slowly. The overall IHTC values of step 5 were higher than those of the other four steps, while the lowest peak IHTC value was present at step 1. When the applied pressure was increased, the IHTC peak value of each step became large accordingly. The empirical equations relating the IHTCs to the pressures, section thicknesses, and temperatures at the casting/mold interface were derived based on the multivariate linear and polynomial regression.

Similar content being viewed by others

References

Sun Z, Ren L, Geng X, Fang L, Wei X, Hu H (2019) Influence of wall stocks on mechanical properties of HPDC AZ91. Key Eng Mater 793:41–45

Zhang X, Fang L, Geng X, Sun Z, Hu H, Nie X (2018) Pouring temperature-dependent tensile properties of squeeze cast magnesium alloy AJ62. Adv Mater Process Technol 4(2):262–271

Bichler L, Elsayed A, Lee K, Ravindran C (2008) Influence of mold and pouring temperatures on hot tearing susceptibility of AZ91D magnesium alloy. Int J Met 2(1):43–54

Pehlke RD, Cookson JM, Hao SW, Krishna P, Kevin TB (2001) Heat transfer at the mold-metal interface in permanent mold casting of aluminum alloys project. Department of Materials Science and Engineering, University of Michigan, Ann Arbor NO. DE-FC07-97ID13559

Browne DJ, O’Mahoney D (2001) Interface heat transfer in investment casting of aluminum alloys. Metall Mater Trans A 32(12):3055–3063

Ferreira IL, Spinelli JE, Nestler B, Garcia A (2008) Influences of solute content, melt superheat and growth direction on the transient metal/mold interfacial heat transfer coefficient during solidification of Sn–Pb alloys. Mater Chem Phys 111(2–3):444–454

Ferreira IL, Spinelli JE, Pires JC, Garcia A (2005) The effect of melt temperature profile on the transient metal/mold heat transfer coefficient during solidification. Mater Sci Eng A 408(1–2):317–325

Arunkumar S, Rao KS, Kumar TP (2008) Spatial variation of heat flux at the metal–mold interface due to mold filling effects in gravity die-casting. Int J Heat Mass Transf 51(11–12):2676–2685

Meneghini A, Tomesani L (2005) Chill material and size effects on HTC evolution in sand casting of aluminum alloys. J Mater Process Technol 162:534–539

Chattopadhyay H (2007) Simulation of transport processes in squeeze casting. J Mater Process Technol 186(1–3):174–178

Aweda JO, Adeyemi MB (2009) Experimental determination of heat transfer coefficients during squeeze casting of aluminium. J Mater Process Technol 209(3):1477–1483

Guo ZP, Xiong SM, Liu BC, Li M, Allison J (2008) Effect of process parameters, casting thickness, and alloys on the interfacial heat-transfer coefficient in the high-pressure die-casting process. Metall Mater Trans A 39(12):2896–2905

Dour G, Dargusch M, Davidson C, Nef A (2005) Development of a non-intrusive heat transfer coefficient gauge and its application to high pressure die casting: effect of the process parameters. J Mater Process Technol 169(2):223–233

Hamasaiid A, Dargusch MS, Davidson CJ, Tovar S, Loulou T, Rezaï-Aria F, Dour G (2007) Effect of mold coating materials and thickness on heat transfer in permanent mold casting of aluminum alloys. Metall Mater Trans A 38(6):1303–1316

Dargusch MS, Hamasaiid A, Dour G (2008) An inverse model to determine the heat transfer coefficient and its evolution with time during solidification of light alloys. Int J Nonlinear Sci Numerical Simulat 9(3):275–282

Hu H (1998) Squeeze casting of magnesium alloys and their composites. J Mater Sci 33:1579–1589

Sun Z, Hu H, Niu X (2012) Experimental study and numerical verification of heat transfer in squeeze casting of aluminum alloy A442. Metall Mater Trans B 43B:1676–1683

Zhang X, Wang M, Sun Z, Hu H (2012) Section thickness-dependent tensile properties of squeeze cast magnesium alloy AM60. China Foundry 9(2):178–183

Fang L, Zhang X, Ren L, Hu H, Nie X, Tjong J (2018) Effect of Ni addition on tensile properties of squeeze cast Al alloy A380. Adv Mater Process Technol 4(2):200–209

Magnesium and magnesium alloys (2000) ASM Speciality handbook, Avedesian MM, baker H (eds). ASM International, USA

Mesquita RA (2016) Tool steels: properties and performance. CRC Press, Taylor & Francis Group, New York

MAGMASOFT 5.3: Manual (2017). http://www.magmasoft.com. Accessed 22 Jan 2020

Yu A (2007) Mathematical modeling and experimental study of squeeze casting of magnesium alloy AM50A and aluminum alloy A356. PhD dissertation, department of mechanical, automotive and materials engineering, University of Windsor, Windsor, Ontario

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (RGPIN-2017-04921), and the University of Windsor for supporting this work. One of the authors (LR) wishes to acknowledge the government of Ontario and the University of Windsor for financial support in the form of an Ontario Graduate Scholarship and a University of Windsor Doctoral Tuition Scholarship, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, L., Hu, A., Fu, Y. et al. Influence of applied pressures and casting section thicknesses on interfacial heat transfer in squeeze casting of magnesium alloy AZ91. Heat Mass Transfer 57, 1107–1120 (2021). https://doi.org/10.1007/s00231-020-03012-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-03012-7