Abstract

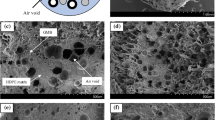

Syntactic foams based on addition cure, room temperature vulcanizing silicone elastomer with two types of microballoons, viz. glass and ceramic, were processed and characterized. The effect of microballoon concentration (varied from 0 to 30 wt%) on the physical, mechanical, thermal, thermo-physical and ablative properties of the foams was investigated. Syntactic foams with glass microballoon (GM) possessed lower density and higher void content compared to those with ceramic microballoon (CM). The specific tensile strength and elastic modulus showed significant improvement; particularly for 20% GM filled system due to good interfacial bonding with silicone matrix. For CM syntactic foam, most of the mechanical properties showed a decline with increase in CM content because of poor interfacial properties. The trend in mechanical properties was corroborated by the microstructure evaluation through scanning electron microscopic (SEM) analyses. The thermo-physical properties such as specific heat, thermal conductivity, thermal diffusivity and co-efficient of thermal expansion showed variations with the type and content of microballoon. Thermo-gravimetric analysis (TGA) showed accelerated thermal decomposition for GM filled system; whereas, CM filled system preserved the thermal stability of silicone along with increase in char residue. Ablative evaluation showed high heat of ablation for GM filled system compared to CM based syntactic foam. The study reveals that syntactic foams based on silicone elastomer with low density and enhanced mechanical properties, suitable for critical weight-sensitive applications, can be formulated with microballoon inclusion. Selection of the appropriate type and concentration of microballoon is crucial in realizing the syntactic foams useful for the intended application.

Similar content being viewed by others

References

Gupta N, Shunmugasamy VC (2011) High strain rate compressive response of syntactic foams: trends in mechanical properties and failure mechanisms. Mater Sci Eng, A 528:7596–7605

Kishore K, Shankar R, Sankaran S (2005) Gradient syntactic foams: Tensile strength, modulus and fractographic features. Mater Sci Eng A 412:153–158

Sankaran S, Ravishankar BN, Sekhar KR, Dasgupta S, Kumar MNJ (2016) Syntactic foams for multifunctional applications. In: Kamal KK (ed) Composite materials—Processing, applications, characterizations. Springer, Germany, pp 281–314

John B, Nair CPR (2014) Syntactic foams. In: Dodiuk H, Goodman SH (eds) Handbook of thermoset plastics, 3rd edn. Elsevier, USA, pp 511–554

Shabde V, Hoo K, Gladysz G (2006) Experimental determination of the thermal conductivity of three-phase syntactic foams. J Mater Sci 41:4061–4073

Gladysz GM, Perry B, Mceachen G, Lula J (2006) Three-phase syntactic foams: structure-property relationships. J Mater Sci 41:4085–4092

Gu J, Yang X, Lv Z, Li N, Liang C, Zhang Q (2016) Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int J Heat Mass Transfer 92:15–22

Zhao W, Kong J, Liu H, Zhuang Q, Gu J, Guo Z (2016) Ultra-high thermally conductive and rapid heat responsive poly(benzobisoxazole) nanocomposites with self-aligned graphene. Nanoscale 8:19984–19993

Kong J, Wang M, Zou J, An L (2015) Soluble and meltable hyperbranched polyborosilazanes toward high-temperature stable SiBCN ceramics. ACS Appl Mater Interfaces 7(12):6733–6744

Gu J, Liang C, Zhao X, Gan B, Qiu H, Guo Y, Yang X, Zhang Q, Wang D-Y (2017) Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos Sci Technol 139(8):83–89

Gu J, Meng X, Tang Y, Li Y, Zhuang Q, Kong J (2017) Hexagonal boron nitride/polymethyl-vinyl siloxane rubber dielectric thermally conductive composites with ideal thermal stabilities. Compos Part A-Appl S 92:27–32

John B, Nair CPR, Ninan KN (2010) Effect of nanoclay on the mechanical, dynamic mechanical and thermal properties of cyanate ester syntactic foams. Mater Sci Eng, A 527(21–22):5435–5443

Alex AS, Kumar V, Rajeev RS, Supriya N, Manu SK, Gouri C, Bandyopadhyay GG, Sekkar V (2016) Effect of organically modified montmorillonite clay on the properties of hydroxyl terminated polydimethyl siloxane. J Adhes Sci Tech 31(13):1496–1513

Bunn P, Mottram JT (1993) Manufacture and compression properties of syntactic foams. Composites 24:565–571

Rizzi E, Papa E, Corigliano A (2000) Mechanical behavior of a syntactic foam: experiments and modeling. Int J Solids Struct 37:5773–5794

Gupta N, Kishore K, Woldesenbet E, Sankaran S (2001) Studies on compressive failure features in syntactic foam material. J Mater Sci 36:4485–4491

Sombatsompop N (1998) Effects of crosslink characteristics on density and swelling behavior of expanded natural rubber vulcanizates. Cell Polym 17:63–74

Gupta N, Woldesenbet E, Mensah P (2004) Compression properties of syntactic foams: effect of cenosphere radius ratio and specimen aspect ratio. Compos Part A-Appl S 35:103–111

Gupta N, Kishore K, Woldesenbet E, Sankaran S (2001) Studies on compressive failure features in syntactic foam material. J Mater Sci 36:4485–4491

Poveda R, Achar S, Gupta N (2012) Thermal expansion of carbon nanofiber-reinforced multiscale polymer composites. JOM J Miner Met Mater Soc 64:1148–1157

Dimchev M, Caeti R, Gupta N (2010) Effect of carbon nanofibers on tensile and compressive characteristics of hollow particle filled composites. Mater Des 31(3):1332–1337

John B, Nair CPR (2010) Update on syntactic foams. iSmithers Rapra, UK

Kenig S, Raiter I, Narkis M (1984) Three-phase silicone based syntactic foams. J Cell Plast 20(6):423–429

Yazicia M, Fahrb P, Shuklab A, Gunesc S, Akay SK (2014) Development of a polymer based syntactic foam for high temperature applications. Acta Phys Pol, A 125:526–528

Bunn P, Mottram JT (1993) Manufacture and compression properties of syntactic foams. Composites 24:565–571

Data sheet of Elastosil® P 7684/60 A/B

Data sheet of Elastosil® P 7684/60 A

Data sheet of Elastosil® P 7684/60 B

Carré A, Lacarrière V, Birch W (2003) Molecular interactions between DNA and an aminated glass substrate. J Coll Interf Sci 260(1):49–55

Carré A, Lacarrière V (2008) Contact angle, wettability and adhesion. Brill Academic Publishers, Netherland, p 267

Liu XM, Thomason JL, Jones FR (2009) The concentration of hydroxyl groups on glass surfaces and their effect on the structure of silane deposits. In: Mittal KL (ed) Silanes and other coupling agents. Brill Academic, Netherland, p 25

Zhuravlev LT (1993) Surface characterization of amorphous silica: a review of work from the former USSR. Colloids Surf A 74(1):71–90

John B, Nair CPR, Devi KA, Ninan KN (2007) Effect of low-density filler on mechanical properties of syntactic foams of cyanate ester. J Mater Sci 42:5398–5405

John B, Nair CPR, Ninan KN (2007) Low-density phenolic syntactic foams: processing and properties. Cell Polym 26(4):229–244

Reed RP, Golda M (1994) Cryogenic properties of unidirectional composites. Cryogenics 34:909–928

Liang J-Z (2014) Estimation of thermal conductivity for polypropylene/hollow glass bead composites. Compos B 56:431–434

Jovanovic JD, Govedarica MN, Dvornic PR, Popovic IG (1998) The thermogravimetric analysis of some polysiloxanes. Polym Degrad Stab 61:87–93

Camino G, Lomakin SM, Lageard M (2002) Thermal polydimethylsiloxane degradation. Part 2. The degradation mechanisms. Polymer 43:2011–2015

Gu J, Yang X, Li C, Kou K (2016) Synthesis of cyanate ester microcapsules via solvent evaporation technique and its application in epoxy resins as a healing agent. Ind Eng Chem Res 55:10941–10946

Gu J, Lv Z, Wu Y, Guo Y, Tian L, Qiu H, Li W, Zhang Q (2017) Dielectric thermally conductive boron nitride/polyimide composites with outstanding thermal stabilities via in situ polymerization electrospinning-hot press method. Compos Part A-Appl S 94:209–216

Camino G, Lomakin SM, Lageard M (2001) Polydimethylsiloxane thermal degradation. Part 1. Kinetic aspects. Polymer 42:2395–2402

Radhakrishnan TS (1999) New method for evaluation of kinetic parameters and mechanism of degradation from pyrolysis–GC studies: thermal degradation of polydimethylsiloxanes. J Appl Poly Sci 73:441–450

Nielsen JM (1979) Degradation of methyl silicone fluids under nitrogen atmosphere at 370 °C. J Appl Polym Sci: Appl Polym Symp 35:223

Buch R, Shields AJ, Kashiwagi T, Cleary T, Steckler K (1998) The influence of surface silica on the pyrolysis of silicones. NISTIR annual conference on fire research

Hshieh FY (1998) Shielding effects of silica-ash layer on the composition of silicones and their possible applications on the fire retardancy of organic polymers. Fire Mater 22:69–76

Helber B, Chazot O, Hubin A, Magin T (2015) Microstructure and gas-surface interaction studies of a low-density carbon-bonded carbon fiber composite in atmospheric entry plasmas. Compos Part A Appl S 72:96–107

Acknowledgements

The authors thank Director, Vikram Sarabhai Space Centre for granting permission to publish this paper. The authors also acknowledge the support from colleagues in Analytical Division, Analytical and Spectroscopic Division and Materials Characterization Division of VSSC for various analytical supports.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Alex, A.S., Thomas, D., Manu, S.K. et al. Addition-cure, room temperature vulcanizing silicone elastomer based syntactic foams with glass and ceramic microballoons. Polym. Bull. 75, 747–767 (2018). https://doi.org/10.1007/s00289-017-2052-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2052-9