Abstract

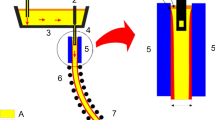

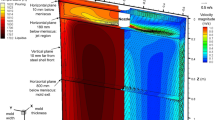

The process of sequential casting of steel, i.e. the procedure that implies a continuous change in the composition of the steel in the casting process of different steel grades, can be easily modelled assuming a perfect and instantaneous mix of the materials in the tundish. However, experimental evidence based on the measure of the local composition of steel billets obtained through this process suggests that the mixing of different steel grades in the tundish cannot be considered either perfect or instantaneous. An improved stochastic model, taking into account these effects, is presented and validated against the experimental results obtained using the laser-induced breakdown spectroscopy technique, assisted by an artificial neural network. In spite of the simplicity of the model proposed, the agreement between its predictions and the experimental results is remarkable.

Similar content being viewed by others

References

J. Campbell, Complete casting handbook: metal casting processes, metallurgy, techniques and design (Elsevier Butterworth-Heinemann, Oxford, 2011)

R. Noll, H. Bette, A. Brysch, M. Kraushaar, I. Mönch, L. Peter, V. Sturm, Spectrochim. Acta Part B At. Spectrosc. 56, 637 (2001)

G. Lorenzetti, S. Legnaioli, E. Grifoni, S. Pagnotta, V. Palleschi, Spectrochim. Acta Part B At. Spectrosc. 112, 1–5 (2015)

T. Delgado, J. Ruiz, L.M. Cabalín, J.J. Laserna, J. Anal. At. Spectrom. 31, 2242 (2016)

L.M. Cabalín, T. Delgado, J. Ruiz, D. Mier, J.J. Laserna, Spectrochim. Acta Part B At. Spectrosc. 146, 93 (2018)

Y. Sahai, T. Emi, ISIJ Int. 36, 667 (1996)

B.G. Thomas, L. Zhang, ISIJ Int. 41, 1181 (2001)

M.R. Aboutalebi, M. Hasan, R.I.L. Guthrie, Metall. Mater. Trans. B 26, 731 (1995)

L. Tang, J. Liu, A. Rong, Z. Yang, Eur. J. Oper. Res. 120, 423 (2000)

D. Mier Vasallo, J. Ciriza Corcuera, J.J. Laraudogoitia Elortegui, Patent n. ES2445466 (2004)

M. Warzecha, T. Merder, H. Pfeifer, J. Pieprzyca, Steel Res. Int. 81, 987 (2010)

A. Bertolini, G. Carelli, F. Francesconi, M. Francesconi, L. Marchesini, P. Marsili, F. Sorrentino, G. Cristoforetti, S. Legnaioli, V. Palleschi, L. Pardini, A. Salvetti, Anal. Bioanal. Chem. 385, 240–247 (2006)

E. D’Andrea, S. Pagnotta, E. Grifoni, G. Lorenzetti, S. Legnaioli, V. Palleschi, B. Lazzerini, Spectrochim. Acta Part B At. Spectrosc. 99, 52–58 (2014)

J.-M. Böhlen, P. Charpié, Steel Times Int. 30, 26 (2006)

Acknowledgements

The authors acknowledge the fruitful discussions with Dr. Arne Bengtson, Swerim AB, Sweden, during the preparation of this work. The research reported in this paper was partially funded by the European Commission through the LACOMORE (Laser-based continuous monitoring and resolution of steel grades in sequence casting machines) project in the framework of the RFCS Research Fund for Coal and Steel (Grant no. RFSR‐CT‐2013‐00034).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mier, D., Nazim Jalali, P., Ramirez Lopez, P. et al. A stochastic model of the process of sequence casting of steel, taking into account imperfect mixing. Appl. Phys. B 125, 65 (2019). https://doi.org/10.1007/s00340-019-7175-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-019-7175-2