Abstract

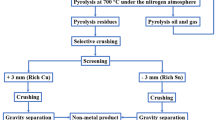

Electrostatic separation is a cleaning physical method to recover metals from waste printed circuit boards (WPCBs), but it has poor separation efficiency for finer sized fractions. In this study, electrostatic separation enhanced by air classification was used to recover residual metals from − 0.5 mm non-metallic fractions in WPCBs. Under the optimal operational factors, concentrate with metal content of 71.55 wt% and recovery of 64.79% was obtained by “air classification + electrostatic separation” process. Morphology analysis showed that large amounts of fine glass fibers adhesion to the surface of metal particles, resulting in low separation efficiency of fine fractions. Air classification can realize separation of metallic particles and non-metallic particles according to the difference of density. And pre-concentration of metal particles in coarse fraction can reduce the load of subsequent separation process. Moreover, the air flow can effectively remove fine non-metallic particles and reduce the influence of adhesion and agglomeration of fine particles on electrostatic separation, so as to improve the separation efficiency of electrostatic separation.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Abdelbasir SM, Hassan SSM, Kamel AH, El-Nasr RS (2018) Status of electronic waste recycling techniques: a review. Environ Sci Pollut Res 25:16533–16547. https://doi.org/10.1007/s11356-018-2136-6

Hao J, Wang Y, Wu Y, Guo F (2020) Metal recovery from waste printed circuit boards: a review for current status and perspectives. Resour Conserv Recycl 157:104787. https://doi.org/10.1016/j.resconrec.2020.104787

Li J, Lopez NBN, Liu L et al (2013) Regional or global WEEE recycling. where to go? Waste Manag 33:923–934. https://doi.org/10.1016/j.wasman.2012.11.011

Liu X, Tanaka M, Matsui Y (2006) Electrical and electronic waste management in China: progress and the barriers to overcome. Waste Manag Res 24:92–101. https://doi.org/10.1177/0734242X06062499

Ghosh B, Ghosh MK, Parhi P et al (2015) Waste printed circuit boards recycling: an extensive assessment of current status. J Clean Prod 94:5–19. https://doi.org/10.1016/j.jclepro.2015.02.024

Zhang G, Wang H, Yang J et al (2018) Application of electric field to a fluidized bed for recovering residual metals from fine particles of the non-metallic fraction of waste printed circuit boards. J Clean Prod 187:1036–1042. https://doi.org/10.1016/j.jclepro.2018.03.282

Zhu X, nan, Ni Y, Wang D zhang, et al (2020) Effect of dissociation size on flotation behavior of waste printed circuit boards. J Clean Prod 265:121840. https://doi.org/10.1016/j.jclepro.2020.121840

He J, Duan C (2017) Recovery of metallic concentrations from waste printed circuit boards via reverse floatation. Waste Manag 60:618–628. https://doi.org/10.1016/j.wasman.2016.11.019

Wang J, Xu Z (2015) Disposing and recycling waste printed circuit boards: disconnecting, resource recovery, and pollution control. Environ Sci Technol 49:721–733. https://doi.org/10.1021/es504833y

Johnson J, Harper EM, Lifset R, Graedel TE (2007) Dining at the periodic table: metals concentrations as they relate to recycling. Environ Sci Technol 41:1759–1765. https://doi.org/10.1021/es060736h

Panyakapo P, Panyakapo M (2008) Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag 28:1581–1588. https://doi.org/10.1016/j.wasman.2007.08.006

Wei B, Li J, Xie H et al (2012) Progress in research of comprehensive utilization of nonmetallic materials from waste printed circuit boards. Procedia Environ Sci 16:500–505. https://doi.org/10.1016/j.proenv.2012.10.069

Zheng Y, Shen Z, Cai C et al (2009) The reuse of nonmetals recycled from waste printed circuit boards as reinforcing fillers in the polypropylene composites. J Hazard Mater 163:600–606. https://doi.org/10.1016/j.jhazmat.2008.07.008

Guo J, Guo J, Cao B et al (2009) Manufacturing process of reproduction plate by nonmetallic materials reclaimed from pulverized printed circuit boards. J Hazard Mater 163:1019–1025. https://doi.org/10.1016/j.jhazmat.2008.07.099

Ma C, Yu J, Wang B et al (2016) Chemical recycling of brominated flame retarded plastics from e-waste for clean fuels production: a review. Renew Sustain Energy Rev 61:433–450. https://doi.org/10.1016/j.rser.2016.04.020

Kim YM, Han TU, Kim S et al (2017) Catalytic co-pyrolysis of epoxy-printed circuit board and plastics over HZSM-5 and HY. J Clean Prod 168:366–374. https://doi.org/10.1016/j.jclepro.2017.08.224

Shokri A, Pahlevani F, Levick K et al (2017) Synthesis of copper-tin nanoparticles from old computer printed circuit boards. J Clean Prod 142:2586–2592. https://doi.org/10.1016/j.jclepro.2016.11.017

Xiao H, Zhou Z, Zhou H et al (2017) Conversion of HBr to Br 2 in the flue gas from the combustion of waste printed circuit boards in post-combustion area. J Clean Prod 161:239–244. https://doi.org/10.1016/j.jclepro.2017.05.117

Zhao C, Zhang X, Shi L (2017) Catalytic pyrolysis characteristics of scrap printed circuit boards by TG-FTIR. Waste Manag 61:354–361. https://doi.org/10.1016/j.wasman.2016.12.019

Li H, Eksteen J, Oraby E (2018) Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): current status and perspectives – a review. Resour Conserv Recycl 139:122–139. https://doi.org/10.1016/j.resconrec.2018.08.007

Baniasadi M, Vakilchap F, Bahaloo-Horeh N et al (2019) Advances in bioleaching as a sustainable method for metal recovery from e-waste: a review. J Ind Eng Chem 76:75–90. https://doi.org/10.1016/j.jiec.2019.03.047

Işıldar A, van Hullebusch ED, Lenz M et al (2019) Biotechnological strategies for the recovery of valuable and critical raw materials from waste electrical and electronic equipment (WEEE) – A review. J Hazard Mater 362:467–481. https://doi.org/10.1016/j.jhazmat.2018.08.050

Cui J, Forssberg E (2003) Mechanical recycling of waste electric and electronic equipment: a review. J Hazard Mater 99:243–263. https://doi.org/10.1016/S0304-3894(03)00061-X

Zhu X, nan, Nie C chen, Wang S sha, et al (2020) Cleaner approach to the recycling of metals in waste printed circuit boards by magnetic and gravity separation. J Clean Prod 248:119235. https://doi.org/10.1016/j.jclepro.2019.119235

He J, He Y, Ge WS et al (2010) Research on the recycling of valuable metals from waste printed circuit boards by eddy current separation. Adv Mater Res 113–116:367–371. https://doi.org/10.4028/www.scientific.net/AMR.113-116.367

Wu J, Li J, Xu Z (2008) Electrostatic separation for recovering metals and nonmetals from waste printed circuit board: Problems and improvements. Environ Sci Technol 42:5272–5276. https://doi.org/10.1021/es800868m

Zhang S, Forssberg E (1997) Mechanical separation-oriented characterization of electronic scrap. Resour Conserv Recycl 21:247–269. https://doi.org/10.1016/S0921-3449(97)00039-6

Zhang G, He Y, Feng Y et al (2018) Recovery of residual metals from fine nonmetallic fractions of waste printed circuit boards using a vibrated gas-solid fluidized bed. Sep Purif Technol 207:321–328. https://doi.org/10.1016/j.seppur.2018.06.017

Zhang G, He Y, Wang H et al (2017) New technology for recovering residual metals from nonmetallic fractions of waste printed circuit boards. Waste Manag 64:228–235. https://doi.org/10.1016/j.wasman.2017.03.030

Li J, Lu H, Guo J et al (2007) Recycle technology for recovering resources and products from waste printed circuit boards. Environ Sci Technol 41:1995–2000. https://doi.org/10.1021/es0618245

Wu J, Qin Y, Zhou Q, Xu Z (2009) Impact of nonconductive powder on electrostatic separation for recycling crushed waste printed circuit board. J Hazard Mater 164:1352–1358. https://doi.org/10.1016/j.jhazmat.2008.09.061

Altun O, Toprak A, Benzer H, Darilmaz O (2016) Multi component modelling of an air classifier. Miner Eng 93:50–56. https://doi.org/10.1016/j.mineng.2016.04.014

Eswaraiah C, Kavitha T, Vidyasagar S, Narayanan SS (2008) Classification of metals and plastics from printed circuit boards (PCB) using air classifier. Chem Eng Process Process Intensif 47:565–576. https://doi.org/10.1016/j.cep.2006.11.010

Lin L, Chen H, Jiang P, Zhang M (2011) Study on resin powder from waste circuit board by airflow separation. Chinese J Environ Eng 5:2–5

Altun O, Benzer H (2014) Selection and mathematical modelling of high efficiency air classifiers. Powder Technol 264:1–8. https://doi.org/10.1016/j.powtec.2014.05.013

Funding

This work is supported by Sichuan Science and Technology Program, Sichuan, China (No. 2021YJ0057).

Author information

Authors and Affiliations

Contributions

ZW: carried out the experiment, analyzed the data, and wrote the manuscript; HL: research and investigation, methods, draft revision; HC: error checking; JX: error checking; QZ: experimental conjecture verification, method.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Z., Li, H., Chen, H. et al. Recovery of residual metals from − 0.5 mm non-metallic fractions in WPCBs using electrostatic separation enhanced by air classification. J Mater Cycles Waste Manag 24, 980–991 (2022). https://doi.org/10.1007/s10163-022-01373-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01373-1