Abstract

The aim of this study is to derive accurate models for quantities characterizing the dynamics of droplets of non-vanishing viscosity in capillaries. In particular, we propose models for the uniform-film thickness separating the droplet from the tube walls, for the droplet front and rear curvatures and pressure jumps, and for the droplet velocity in a range of capillary numbers, Ca, from \(10^{-4}\) to 1 and inner-to-outer viscosity ratios, \(\lambda\), from 0, i.e. a bubble, to high-viscosity droplets. Theoretical asymptotic results obtained in the limit of small capillary number are combined with accurate numerical simulations at larger Ca. With these models at hand, we can compute the pressure drop induced by the droplet. The film thickness at low capillary numbers (\(Ca<10^{-3}\)) agrees well with Bretherton’s scaling for bubbles as long as \(\lambda <1\). For larger viscosity ratios, the film thickness increases monotonically, before saturating for \(\lambda>10^3\) to a value \(2^{2/3}\) times larger than the film thickness of a bubble. At larger capillary numbers, the film thickness follows the rational function proposed by Aussillous and Quéré (Phys Fluids 12(10):2367–2371, 2000) for bubbles, with a fitting coefficient which is viscosity-ratio dependent. This coefficient modifies the value to which the film thickness saturates at large capillary numbers. The velocity of the droplet is found to be strongly dependent on the capillary number and viscosity ratio. We also show that the normal viscous stresses at the front and rear caps of the droplets cannot be neglected when calculating the pressure drop for \(Ca>10^{-3}\).

Similar content being viewed by others

Abbreviations

- A :

-

Coefficient for flow profile

- B :

-

Coefficient for flow profile

- C :

-

Coefficient for interface profile of static meniscus

- \(\mathscr {C}\) :

-

Mean curvature of droplet interface

- D :

-

Coefficient for interface profile of static meniscus

- \(c_1\), \(c_2\) :

-

Coefficient for fitting law of P, \(\bar{P}\)

- Ca :

-

Capillary number based on droplet velocity

- \(Ca_{\infty }\) :

-

Capillary number based on mean outer velocity

- F :

-

Coefficient for minimum film thickness

- \(\bar{F}\) :

-

Averaged F coefficient

- G :

-

Coefficient for minimum film thickness

- H :

-

Thickness of film between wall and droplet

- \(H_{\textsf {min}}\) :

-

Minimum film thickness

- \(H_{\infty }\) :

-

Uniform film thickness

- \(H_{\infty }^{\star }\) :

-

Critical uniform film thickness for recirculations

- K :

-

Coefficient for linearized lubrication equation

- \({\mathbf {I}}\) :

-

Identity tensor

- \(L_d\) :

-

Droplet length

- M :

-

Coefficient for pressure model

- m :

-

Rescaled viscosity ratio

- N :

-

Coefficient for pressure model

- \(\mathbf {n}\) :

-

Unit vector normal to the droplet interface

- O :

-

Coefficient for pressure model

- P :

-

Coefficient for interface profile of static meniscus

- \(\bar{P}\) :

-

Averaged P coefficient

- p :

-

Pressure

- \(p_{\textsf {linear}}\) :

-

Pressure if constant gradient

- Q :

-

Coefficient for uniform film thickness model

- q :

-

Volume flux

- R :

-

Capillary tube radius or half width

- Re :

-

Reynolds number

- r :

-

Radial direction (axisymmetric geometry)

- \(\tilde{r}\) :

-

Half width of droplet

- S :

-

Coefficient for classical pressure model

- t :

-

Time

- T :

-

Coefficient for plane curvature model

- \(U_{d}\) :

-

Droplet velocity

- \(U_{\infty }\) :

-

Average outer flow velocity

- \(u_{\infty }\) :

-

Outer far-field velocity profile

- \(\mathbf {u}\) :

-

Velocity field

- u :

-

Streamwise velocity

- v :

-

Spanwise velocity

- x :

-

Streamwise direction (planar geometry)

- y :

-

Spanwise direction (planar geometry)

- z :

-

Axial direction (axisymmetric geometry)

- Z :

-

Coefficient for plane curvature model

- \(\alpha\) :

-

Parameter for solution of linear lubrication equation

- \(\beta\) :

-

Coefficient for plane curvature model

- \(\Delta\) :

-

Difference between inner and outer quantities

- \(\Delta p^{\text {NP}}\) :

-

Pressure correction due to non-parallel flow effects

- \(\Delta p_{\textsf {tot}}\) :

-

Total pressure drop

- \(\gamma\) :

-

Surface tension

- \(\eta\) :

-

Rescaled film thickness

- \(\kappa\) :

-

Plane curvature of droplet interface in the (z, r) or (x, y) plane

- \(\kappa _{f,r}\) :

-

Plane curvature at the front/rear droplet extremities

- \(\lambda\) :

-

Inner-to-outer dynamic viscosity ratio

- \(\mu\) :

-

Dynamic viscosity

- \(\xi\) :

-

Rescaled axial direction

- \(\varvec{\sigma} \) :

-

Total stress tensor

- \(\varvec{\tau } \) :

-

Viscous stress tensor

- \(\phi\) :

-

Phase of solution of linear lubrication equation

- \(\chi\) :

-

Geometric coefficient

- \(\Omega\) :

-

Droplet volume or area

- f :

-

Front cap

- i :

-

Inner

- o :

-

Outer

- r :

-

Rear cap

- zz :

-

Normal tensor component in the axial direction

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- ALE:

-

Arbitrary Lagrangian–Eulerian

- BIM:

-

Boundary integral method

- FEM:

-

Finite element method

References

Abadie T, Aubin J, Legendre D, Xuereb C (2012) Hydrodynamics of gas-liquid Taylor flow in rectangular microchannels. Microfluid Nanofluid 12(1–4):355–369

Anjos G, Mangiavacchi N, Borhani N, Thome JR (2014) 3D ALE finite-element method for two-phase flows with phase change. Heat Transfer Eng 35(5):537–547

Anjos GR, Borhani N, Mangiavacchi N, Thome JR (2014) A 3D moving mesh finite element method for two-phase flows. J Comput Phys 270:366–377

Anna SL (2016) Droplets and bubbles in microfluidic devices. Annu Rev Fluid Mech 48:285–309

Aussillous P, Quéré D (2000) Quick deposition of a fluid on the wall of a tube. Phys Fluids 12(10):2367–2371

Baroud CN, Gallaire F, Dangla R (2010) Dynamics of microfluidic droplets. Lab Chip 10(16):2032–2045

Boden S, dos Santos Rolo T, Baumbach T, Hampel U (2014) Synchrotron radiation microtomography of Taylor bubbles in capillary two-phase flow. Exp Fluids 55(7):1768

Boos W, Thess A (1997) Thermocapillary flow in a Hele-Shaw cell. J Fluid Mech 352:305–330

Bretherton FP (1961) The motion of long bubbles in tubes. J Fluid Mech 10(02):166–188

Cantat I (2013) Liquid meniscus friction on a wet plate: Bubbles, lamellae, and foams. Phys Fluids 25(3):031303

Chen JD (1986) Measuring the film thickness surrounding a bubble inside a capillary. J Colloid Interface Sci 109(2):341–349

Cherukumudi A, Klaseboer E, Khan SA, Manica R (2015) Prediction of the shape and pressure drop of Taylor bubbles in circular tubes. Microfluid Nanofluid 19(5):1221–1233

de Ryck A (2002) The effect of weak inertia on the emptying of a tube. Phys Fluids 14(7):2102–2108

Derjaguin B (1943) On the thickness of the liquid film adhering to the walls of a vessel after emptying. Acta Physicochimica URSS 20(43):349–352

Eggers J, Villermaux E (2008) Physics of liquid jets. Rep Progr Phys 71(3):036601

Fairbrother F, Stubbs AE (1935) Studies in electro-endosmosis. Part VI. The bubble-tube method of measurement. J Chem Soc 1:527–529

Fuerstman MJ, Lai A, Thurlow ME, Shevkoplyas SS, Stone HA, Whitesides GM (2007) The pressure drop along rectangular microchannels containing bubbles. Lab Chip 7(11):1479–1489

Ganesan S, Hahn A, Simon K, Tobiska L (2017) ALE-FEM for two-phase and free surface flows with surfactants. In: Bothe D, Reusken A (eds) Transport Processes at Fluidic Interfaces. Springer International Publishing, Cham, pp 5–31

Ganesan S, Tobiska L (2012) Arbitrary Lagrangian-Eulerian finite-element method for computation of two-phase flows with soluble surfactants. J Comput Phys 231(9):3685–3702

Giavedoni MD, Saita FA (1997) The axisymmetric and plane cases of a gas phase steadily displacing a Newtonian liquid - A simultaneous solution of the governing equations. Phys Fluids 9(8):2420–2428

Giavedoni MD, Saita FA (1999) The rear meniscus of a long bubble steadily displacing a Newtonian liquid in a capillary tube. Phys Fluids 11(4):786–794

Günther A, Jensen KF (2006) Multiphase microfluidics: from flow characteristics to chemical and materials synthesis. Lab Chip 6(12):1487–1503

Gupta R, Leung SSY, Manica R, Fletcher DF, Haynes BS (2013) Three dimensional effects in taylor flow in circular microchannels. La Houille Blanche 2:60–67

Hadikhani P, Hashemi SMH, Balestra G, Zhu L, Modestino MA, Gallaire F, Psaltis D (2018) Inertial manipulation of bubbles in rectangular microfluidic channels. Lab Chip 18(7):1035–1046

Han Y, Shikazono N (2009) Measurement of liquid film thickness in micro square channel. Int J Multiph Flow 35(10):896–903

Hazel AL, Heil M, Waters SL, Oliver JM (2012) On the liquid lining in fluid-conveying curved tubes. J Fluid Mech 705:213–233

Heil M (2001) Finite Reynolds number effects in the Bretherton problem. Phys Fluids 13(9):2517–2521

Herrada MA, Ganan-Calvo AM, Guillot P (2008) Spatiotemporal instability of a confined capillary jet. Phys Rev E 78(4):046312

Hodges SR, Jensen OE, Rallison JM (2004) The motion of a viscous drop through a cylindrical tube. J Fluid Mech 501:279–301

Huerre A, Theodoly O, Leshansky AM, Valignat MP, Cantat I, Jullien MC (2015) Droplets in microchannels: dynamical properties of the lubrication film. Phys Rev Lett 115(6):064501

Jakiela S, Makulska S, Korczyk PM, Garstecki P (2011) Speed of flow of individual droplets in microfluidic channels as a function of the capillary number, volume of droplets and contrast of viscosities. Lab Chip 11(21):3603–3608

Khodaparast S, Kim MK, Silpe JE, Stone HA (2017) Bubble-driven detachment of bacteria from confined microgeometries. Environ Sci Technol 51(3):1340–1347

Khodaparast S, Magnini M, Borhani N, Thome JR (2015) Dynamics of isolated confined air bubbles in liquid flows through circular microchannels: an experimental and numerical study. Microfluid Nanofluid 19(1):209–234

Klaseboer E, Gupta R, Manica R (2014) An extended Bretherton model for long Taylor bubbles at moderate capillary numbers. Phys Fluids 26(3):032107

Köhler J, Cahill B (2014) Micro-segmented flow: applications in chemistry and biology. biological and medical physics, biomedical engineering. Springer, Berlin Heidelberg

Kreutzer MT, Kapteijn F, Moulijn JA, Kleijn CR, Heiszwolf JJ (2005) Inertial and interfacial effects on pressure drop of Taylor flow in capillaries. AIChE J 51(9):2428–2440

Lac E, Sherwood JD (2009) Motion of a drop along the centreline of a capillary in a pressure-driven flow. J Fluid Mech 640:27–54

Ładosz A, Rigger E, von Rohr PR (2016) Pressure drop of three-phase liquid-liquid-gas slug flow in round microchannels. Microfluid Nanofluid 20(3):49

Landau L, Levich B (1942) Dragging of a Liquid by a moving plate. Acta Physicochimica URSS 17(42):42–54

Langewisch DR, Buongiorno J (2015) Prediction of film thickness, bubble velocity, and pressure drop for capillary slug flow using a CFD-generated database. Int J Heat Fluid Flow 54:250–257

Leung SSY, Gupta R, Fletcher DF, Haynes BS (2011) Effect of flow characteristics on Taylor flow heat transfer. Indus Eng Chem Res 51(4):2010–2020

Li J (2016) Macroscopic model for head-on binary droplet collisions in a gaseous medium. Phys Rev Lett 117(21):214502

Magnini M, Ferrari A, Thome JR, Stone HA (2017) Undulations on the surface of elongated bubbles in confined gas–liquid flows. Phys Rev Fluids 2(8):084001

Martinez MJ, Udell KS (1990) Axisymmetric creeping motion of drops through circular tubes. J Fluid Mech 210:565–591

Mikaelian D, Haut B, Scheid B (2015) Bubbly flow and gas-liquid mass transfer in square and circular microchannels for stress-free and rigid interfaces: dissolution model. Microfluid Nanofluid 19(4):899–911

Nagel M, Gallaire F (2015) Boundary elements method for microfluidic two-phase flows in shallow channels. Comput Fluids 107:272–284

Park CW, Homsy GM (1984) Two-phase displacement in Hele-Shaw cells: theory. J Fluid Mech 139:291–308

Ratulowski J, Chang HC (1989) Transport of gas bubbles in capillaries. Phys Fluids A Fluid Dyn 1(10):1642–1655

Reinelt DA, Saffman PG (1985) The penetration of a finger into a viscous fluid in a channel and tube. SIAM J Sci Stat Comput 6(3):542–561

Rivero-Rodriguez J, Scheid B (2018) Bubble dynamics in microchannels: inertial and capillary migration forces. J Fluid Mech 842:215–247

Saffman PG, Taylor G (1958) The penetration of a fluid into a porous medium or Hele-Shaw cell containing a more viscous liquid. Proc R Soc Lond A 245(1242):312–329

Schwartz LW, Princen HM, Kiss AD (1986) On the motion of bubbles in capillary tubes. J Fluid Mech 172:259–275

Shen EI, Udell KS (1985) A finite element study of low Reynolds number two-phase flow in cylindrical tubes. J Appl Mech 52(2):253–256

Stone HA (2010) Interfaces: in fluid mechanics and across disciplines. J Fluid Mech 645:1–25

Stone HA, Stroock AD, Ajdari A (2004) Engineering flows in small devices: microfluidics toward a lab-on-a-chip. Annu Rev Fluid Mech 36:381–411

Taylor GI (1961) Deposition of a viscous fluid on the wall of a tube. J Fluid Mech 10(02):161–165

Tsai TM, Miksis MJ (1994) Dynamics of a drop in a constricted capillary tube. J Fluid Mech 274:197–217

Warnier MJF, De Croon MM, Rebrov EV, Schouten JC (2010) Pressure drop of gas-liquid Taylor flow in round micro-capillaries for low to intermediate Reynolds numbers. Microfluid Nanofluid 8(1):33

Wong H, Radke CJ, Morris S (1995) The motion of long bubbles in polygonal capillaries. Part 1. Thin films. J Fluid Mech 292:71–94

Wong H, Radke CJ, Morris S (1995) The motion of long bubbles in polygonal capillaries. Part 2. Drag, fluid pressure and fluid flow. J Fluid Mech 292:95–110

Zhu L, Gallaire F (2016) A pancake droplet translating in a Hele-Shaw cell: lubrication film and flow field. J Fluid Mech 798:955–969

Acknowledgements

This work was funded by ERC Grant no. ‘SIMCOMICS 280117’. L.Z. gratefully acknowledges the VR International Postdoc Grant from Swedish Research Council ‘2015-06334’ for financial support. The authors would like to acknowledge the valuable comments from the anonymous referees that helped to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix 1: Derivation of the flow profiles in the thin-film region for the planar configuration

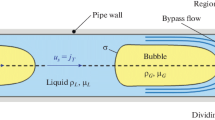

Consider an axial location in the thin-film region. The velocity profiles inside, \(u_i\), and outside, \(u_o\), of the droplet can be described by:

where \(p_i\) and \(p_o\) are the inner, respectively outer, pressures, and \(A_i\), \(B_i\), \(A_o\) and \(B_o\) are real constants to be determined. Given the symmetry at \(r=0\) of the inner velocity, \(A_i=0\). The other constants are found by imposing the no-slip boundary condition at the channel walls \(u(R) = -U_d\) in the droplet reference frame, the continuity of velocities at the interface located at \(r=R-H\), \(u_i(R-H) = u_o(R-H)\), and the continuity of tangential stresses at the interface

Eventually one obtains:

Appendix 2: Derivation of the interface profile equation for the planar configuration

The flow rates at any axial location where the external film thickness is H are:

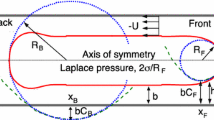

In the droplet reference frame, the flow rate of the inner phase has to vanish, \(q_i =0\). Furthermore, in the region where the film is uniform (see Fig. 11), \(H=H_{\infty }\), the inner and outer pressure gradients have to be equal. Using these two conditions, one can solve for the pressure gradient in the uniform film region

and for the outer flow rate, where the limit \(H_{\infty }/R \ll 1\) is considered:

The pressure gradients in the dynamic meniscus regions are no longer equal and their difference is proportional to the deformation of the interface \(r=R-H\). Under the assumption of a quasi-parallel flow, and neglecting the viscous contribution in view of the lubrication assumption, the Laplace’s law imposes:

Knowing \(q_i\) and \(q_o\), Eqs. (58), (59) can be solved for the unknown pressure gradients \(\mathrm{{d}}p_i/\mathrm{{d}}z\), \(\mathrm{{d}}p_o/\mathrm{{d}}z\) as a function of H:

and substituted into Eq. (62). Following Bretherton (1961), the resulting equation can be put in an universal form by the substitutions \(H = H_{\infty } \eta\) and \(z = H_{\infty } (3 Ca)^{-1/3} \xi\). In the limit of \(H_{\infty }/R\rightarrow 0\), the governing equation for the interface profile reads:

where

is the rescaled viscosity ratio.

Appendix 3: Derivation of the droplet velocity model for the planar configuration

The velocity profiles in the uniform film region have been derived in “Appendix 1”. In particular, the inner and outer volumetric fluxes are given by Eqs. (58) and (59), respectively. At the location where \(H=H_{\infty }\) the interface is flat and the pressure gradients are equal, \(\mathrm{{d}}p_i/\mathrm{{d}}z=\mathrm{{d}}p_o/\mathrm{{d}}z=\mathrm{{d}}p/\mathrm{{d}}z\). Furthermore, mass conservation imposes that \(q_o= 2R (U_{\infty }-U_d)\) and since we are in the reference frame of the droplet, \(q_i=0\). The system of two equations can be solved for the pressure gradient

and the droplet velocity

The relative velocity of the planar droplet reads

Appendix 4: Derivation of the critical uniform film thickness for the appearance of the recirculation regions

The velocity profile in the channel away from the droplet is given by Eq. (11) for the axisymmetric configuration and by

for the planar one. The droplet velocity for the former case is given by Eq. (32), whereas for the latter it is given by Eq. (68). With the use of Eqs. (32) and (68), the velocity \(u_{\infty }\) can be expressed as a function of \(H_{\infty }/R\). The critical uniform film thickness for the appearance of recirculation regions, \(H_{\infty }^{\star }\), is obtained by solving \(u_{\infty }(0) = 0\), resulting in Eqs. (12) and (13) for the axisymmetric and planar configurations, respectively.

Appendix 5: Fitting laws for the model coefficients

The model coefficients Q in Eq. (30), G in Eq. (38), \(T_{f,r}\) and \(Z_{f,r}\) in Eq. (41) and \(M_{f,r}\), \(N_{f,r}\) and \(O_{f,r}\) in Eq. (44) can be well approximated by the rational function

where the constants \(a_i\) with \(i=0,..,3\) and \(b_j\) with \(j=0,..,2\) are given in Tables 1 and 2 for the axisymmetric and planar geometries, respectively.

Appendix 6: Additional results

For the sake of clarity, the results for \(\lambda = 0\) and 100 are shown in the appendix rather than in the main text, except for the normal viscous stresses jump, whose results for \(\lambda = 0\) are presented in the main text as for \(\lambda = 1\) the normal viscous stress jumps are small (Figs. 25, 26, 27, 28, 29, 30).

Uniform film thickness given by Eq. (30) (lines) and FEM-ALE numerical results (symbols) as a function of the droplet capillary number for \(\lambda = 0\) (a) and 100 (b) and both axisymmetric (blue solid line, full symbols) and planar (dashed red line, empty symbols) geometries. (Color figure online)

Minimum film thickness given by Eq. (38) (lines) and FEM-ALE numerical results (symbols) as a function of the droplet capillary number for \(\lambda = 0\) (a) and 100 (b) and both axisymmetric (blue solid line, full symbols) and planar (dashed red line, empty symbols) geometries. (Color figure online)

Curvature \(\kappa _f\) of the front meniscus predicted by the model Eq. (41) (lines) and FEM-ALE data (symbols) versus Ca for both axisymmetric (blue line, full symbols) and planar (red dashed line, empty symbols) geometries, where the viscosity ratio is \(\lambda = 0\) (a) and 100 (b). (Color figure online)

The rear counterpart \(\kappa _r\) of Fig. 27. (Color figure online)

Front pressure jump \(\Delta p_f\) given by Eq. (43) (solid lines) and front normal viscous stress jump \(\Delta \tau _{{zz}_{f}}\) by Eq. (44) (inset, solid lines) and FEM-ALE data (symbols) versus Ca for both axisymmetric (blue line, full symbols) and planar (red line, empty symbols) geometries, where the viscosity ratio is \(\lambda = 1\) (a) and 100 (b). The dashed lines correspond to the improved pressure jump model Eq. (46). Note the different scale in the insets. (Color figure online)

The rear counterpart, pressure jump \(\Delta p_r\) and normal viscous stress jump \(\Delta \tau _{{zz}_{r}}\), of Fig. 29. (Color figure online)

Pressure correction due to non-parallel flow effects at the rear (a) and front (b) outer sides of the interface for \(\lambda = 0.04\) (blue squares), 0.12 (red crosses), 1 (yellow circles), 15 (purple stars) and 50 (green diamonds) for the axisymmetric configuration. The results are obtained from FEM-ALE numerical simulations. (Color figure online)

Pressure correction due to non-parallel flow effects at the rear (a) and front (b) inner sides of the interface for \(\lambda = 0.04\) (blue squares), 0.12 (red crosses), 1 (yellow circles), 15 (purple stars) and 50 (green diamonds) for the axisymmetric configuration. The results are obtained from FEM-ALE numerical simulations. (Color figure online)

Appendix 7: Pressure corrections due to non-parallel flow

Some typical total stresses corrections at the outer and inner sides of the droplet interface as a function of Ca and for different viscosity ratios \(\lambda\) are shown in Figs. 31 and 32, respectively.

Rights and permissions

About this article

Cite this article

Balestra, G., Zhu, L. & Gallaire, F. Viscous Taylor droplets in axisymmetric and planar tubes: from Bretherton’s theory to empirical models. Microfluid Nanofluid 22, 67 (2018). https://doi.org/10.1007/s10404-018-2084-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-018-2084-y