Abstract

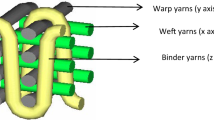

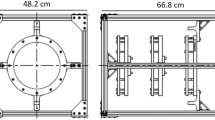

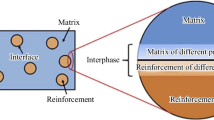

A composite material consisting of carbon fiber fabric and polyurethane resin was used to fabricate circular tubes by resin transfer molding. The composite tubes were tested under both axial static compression and axial impact. To establish delamination criterion for this composite material, short-beam tests and curved-beam tests were executed, and it was verified by step cantilever-beam tests. The short-beam and curved-beam tests indicate that the interlaminar shear and tensile strengths of the composite are around 54.0 MPa and 8.8 MPa, respectively. Also the established delamination criterion has nice prediction for the delamination of the step cantilever-beam test. In addition to the delamination criterion, the finite element analysis with progressive failure was applied and could predict agreeable values on the total absorbed energy and the specific energy absorption of the braided composite tube under both the static and dynamic tests. These indicate that the present analysis could catch the axial crushing behavior of the braided composite tubes.

Similar content being viewed by others

References

Siromani, D., Henderson, G., Mikita, D., Mirarchi, K., Park, R., Smolko, J., Awerbuch, J., Tan, T.M.: An experimental study on the effect of failure trigger mechanisms on the energy absorption capability of CFRP tubes under axial compression. Compos. Part A. 64, 25–35 (2014)

Huang, J., Wang, X.: Numerical and experimental investigations on the axial crushing response of composite tubes. Compos. Struct. 91, 222–228 (2009)

Xiao, X., Botkin, M.E., Johnson, N.L.: Axial crush simulation of braided carbon tubes using MAT 58 in LS-DYNA. Thin Wall. Struct. 47, 740–749 (2009)

McGrefor, C.J., Vaxiri, R., Xiao, X.: Finite element modeling of the progressive crushing of braided composite tubes under axial impact. Int. J. Impact Eng. 37, 662–672 (2010)

Hwang, S.H., Yu, H.L., Liu, Y.J., Chen, Y., Chen, S.C., Hsieh, Y.C.: Progressive failure of metal-composite hybrid wheels under impact. J. Mech. Sci. Technol. 32, 223–229 (2018)

Hou, T., Pearce, G.M.K., Prusty, B.G., Kelly, D.W., Thomson, R.S.: Pressurized composite tubes as variable load energy absorbers. Compos. Struct. 120, 346–357 (2015)

Liu, Q., Xing, H., Ju, Y., Qu, Z., Li, Q.: Quasi-static axial crushing and transverse bending of double hat shaped CFRP tubes. Compos. Struct. 117(1–11), 1–11 (2014)

Mahdi, E., Hamouda, A.M.S., Sahari, B.B., Khalid, Y.A.: On the collapse of cotton/epoxy tubes under axial static loading. Appl. Compos. Mater. 10, 67–84 (2003)

McGrefor, C.J., Vaxiri, R., Poursartip, A., Xiao, X.: Simulation of progressive damage development in braided composite tubes under axial compression. Compos. Part A. 38, 2247–2259 (2007)

Liu, Q., Qu, Z., Mo, Z., Li, Q., Qu, D.: Experimental investigation into dynamic axial impact responses of double hat shaped CFRP tubes. Compos. Part B. 79, 494–504 (2015)

McGrefor, C.J., Vaxiri, R., Xiao, X.: Finite element modeling of the progressive crushing of braided composite tubes under axial impact. Int. J. Impact Eng. 37, 662–672 (2010)

Chen, D., Sun, G., Meng, M., Li, G., Li, Q.: Residual crashworthiness of CFRP structures with pre-impact damage – an experimental and numerical study. Int. J. Mech. Sci. 149, 122–135 (2018)

Boria, S., Scattina, A., Belingardi, G.: Axial energy absorption of CFRP truncated cones. Compos. Struct. 130, 18–28 (2015)

Alkoles, O.M.S., Mahdi, E., Haouda, A.M.S., Sahari, B.B.: Ellipticity ratio effects in the energy absorption of axially crushed composite tubes. Appl. Compos. Mater. 10, 339–363 (2003)

Zhang, Z., Sun, W., Zhao, Y., Hou, S.: Crashworthiness of different composite tubes by experiments and simulations. Compos. Part B. 143, 86–95 (2018)

Sivagurunathan, R., Way, S.L.T., Sivagurunathan, L., Yaakob, M.Y.: The effects of triggering mechanisms on the energy absorption capability of circular jute/epoxy composite tubes under quasi-static axial loading. Appl. Compos. Mater. 25, 1401–1417 (2018)

Tong, Y., Xu, Y.: Improvement of crash energy absorption of 2D braided composite tubes through an innovative chamfer external trigger. Int. J. Impact Eng. 111, 11–20 (2017)

Sun, G., Yu, H., Wang, Z., Hiao, Z., Li, Q.: Energy absorption mechanics and design optimization of CFRP/aluminium hybrid structures for transverse loading. Int. J. Mech. Sci. 150, 767–783 (2019)

Zhu, G., Sun, G., Yu, H., Li, S., Li, Q.: Energy absorption of metal, composite and metal/composite hubrid structures under oblique crushing loading. Int. J. Mech. Sci. 135, 458–483 (2018)

Sun, G., Li, S., Li, G., Li, Q.: On crashing behaviors of aluminium/CFRP tubes subjected to axial and oblique loading: an experimental study. Compos. Part B. 145, 47–56 (2018)

Sun, G., Wang, Z., Hong, J., Song, K., Li, Q.: Experimental investigation of the quasi-static axial crushing behavior of filament-wound CFRP and aluminum/CFRP hybrid tubes. Compos. Struct. 194, 208–225 (2018)

Su, G., Wang, Z., Yu, H., Gong, Z., Li, Q.: Experimental and numerical investigation into the crashworthiness of metal-foam-composite hybrid structures. Compos. Struct. 209, 535–547 (2019)

Reuter, C., Sauerland, K.H., Tröster, T.: Experimental and numerical crushing analysis of circular CFRP tubes under axial impact loading. Compos. Struct. 174, 33–44 (2017)

ASTM D2344/D2344M-13, Standard test method for short-beam strength of polymer matrix composite materials and their laminates, ASTM International, West Conshohocken, PA, (2013)

ASTM D6415/D6415M-06, Standard test method for measuring the curved beam strength of a fiber-reinforced polymer-matrix composite. ASTM International, West Conshohocken, PA, (2006)

Hwang, S.F., Liu, H.T.: Prediction of elastic constants of carbon fabric/polyurethane composites. Solid State Phenom. 258, 233–236 (2017)

Chang, F.K., Chang, K.Y.: A progressive damage model for laminated composites containing stress concentration. J. Compos. Mater. 21, 834–855 (1987)

Acknowledgements

The financial support from Ministry of Science and Technology, Taiwan through MOST 106-2221-E-224-021 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hwang, SF., Chang, YC. Axial Crushing Behavior of Braided Carbon/Polyurethane Composite Tubes. Appl Compos Mater 26, 1281–1297 (2019). https://doi.org/10.1007/s10443-019-09780-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09780-8