Abstract

In this study, a gradually increased hydro-mechanical treatments duration were applied to native hemp bast fibres with a traditional pulp and paper beating device (laboratory Valley beater). There is often a trade-off between the treatment applied to the fibres and the effect on their integrity. The multimodal analysis provided an understanding of the beating impact on the fibres at multiple scales and the experimental design made it possible to distinguish the effects of hydro- and hydro-mechanical treatment. Porosity analyses showed that beating treatment doubled the macroporosity and possibly reduced nanoporosity between the cellulose microfibrils. The beating irregularly extracted the amorphous components known to be preferentially located in the middle lamellae and the primary cell walls rather than in the secondary walls, the overall increasing the crystallinity of cellulose from 49.3 to 59.1%, but a non-significant change in the indentation moduli of the cell wall was observed. In addition, beating treatments with two distinct mechanical severities showed a disorganization of the cellulose conformation, which significant dropped the indention moduli by 11.2 GPa and 8.4 GPa for 10 and 20 min of Valley beater hydro-mechanical treatment, respectively, compared to hydro-treated hemp fibres (16.6 GPa). Pearson’s correlation coefficients between physicochemical features and the final indentation moduli were calculated. Strong positive correlations were highlighted between the cellulose crystallinity and rhamnose, galactose and mannose as non-cellulosic polysaccharide components of the cell wall.

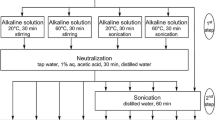

Graphical abstract

Similar content being viewed by others

Abbreviations

- DVS:

-

Dynamic vapour sorption

- HPAEC-PAD:

-

High-performance anion-exchange chromatography with pulsed amperometric detection

- HPLC:

-

High-performance liquid chromatography

- MFA:

-

Microfibrillar angle

- MIP:

-

Mercury intrusion porosimetry

- NCP’s:

-

Non cellulosic polysaccharides

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

References

Adusumalli RB, Passas R, Sreedhar I, Krishnamurthy B, Kombaiah B, Montagne A (2014) Nanoindentation of bleached and refined pulp fibres. IJMatEI 5:138–150. https://doi.org/10.1504/ijmatei.2014.060320

Akmar PF, Yusoff MNM, Kennedy JF, Knill CJ (2000) Compositional analysis of oil palm trunk fibers. In: Cellulosic pulps, fibres and materials. Woodhead Publishing, pp 227–234

Andersons J, Spārniņš E, Poriķe E (2009) Strength and damage of elementary flax fibers extracted from tow and long line flax. J Compos Mater 43:2653–2664. https://doi.org/10.1177/0021998309345035

Arnould O, Siniscalco D, Bourmaud A, Le Duigou A, Baley C (2017) Better insight into the nano-mechanical properties of flax fibre cell walls. Ind Crop Prod 97:224–228. https://doi.org/10.1016/j.indcrop.2016.12.020

Ausias G, Bourmaud A, Coroller G, Baley C (2013) Study of the fibre morphology stability in polypropylene-flax composites. Polym degrad Stabil 98:1216–1224. https://doi.org/10.1016/j.polymdegradstab.2013.03.006

Beaugrand J, Berzin F (2012) Lignocellulosic fiber reinforced composites: influence of compounding conditions on defibrization and mechanical properties. J Appl Polym Sci 128:1227–1238. https://doi.org/10.1002/app.38468

Beaugrand J, Guessasma S (2015) Scenarios of crack propagation in bast fibers: combining experimental and finite element approaches. Compos Struct 133:667–678. https://doi.org/10.1016/j.compstruct.2015.07.119

Beaugrand J, Guessasma S, Maigret J-E (2017) Damage mechanisms in defected natural fibers. Sci Rep UK 7:14041. https://doi.org/10.1038/s41598-017-14514-6

Berzin F, Vergnes B, Beaugrand J (2014) Evolution of lignocellulosic fibre lengths along the screw profile during twin screw compounding with polycaprolactone. Compos Part A Appl S 59:30–36. https://doi.org/10.1016/j.compositesa.2013.12.008

Bourmaud A, Baley C (2009) Rigidity analysis of polypropylene/vegetal fibre composites after recycling. Polym Degrad Stabil 94:297–305. https://doi.org/10.1016/j.polymdegradstab.2008.12.010

Bourmaud A, Malvestio J, Lenoir N, Siniscalco D, Habrant A, King A, Legland D, Baley C, Beaugrand J (2017) Exploring the mechanical performance and in-planta architecture of secondary hemp fibres. Ind Crop Prod 108:1–5. https://doi.org/10.1016/j.indcrop.2017.06.010

Bourmaud A, Beaugrand J, Shah DU, Placet V, Baley C (2018) Towards the design of high-performance plant fibre composites. Prog Mater Sci 97:347–408. https://doi.org/10.1016/j.pmatsci.2018.05.005

Burgert I, Keplinger T (2013) Plant micro- and nanomechanics: experimental techniques for plant cell-wall analysis. J Exp Bot 64:4635–4649. https://doi.org/10.1093/jxb/ert255

Carrier M, Loppinet-Serani A, Denux D, Lasnier J-M, Ham-Pichavant F, Cansell F, Aymonier C (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenergy 35:298–307. https://doi.org/10.1016/j.biombioe.2010.08.067

Célino A, Fréour S, Jacquemin F, Casari P (2013) The hygroscopic behavior of plant fibers: a review. Front Chem 1:43. https://doi.org/10.3389/fchem.2013.00043

Célino A, Gonçalves O, Jacquemin F, Fréour S (2014) Qualitative and quantitative assessment of water sorption in natural fibres using ATR-FTIR spectroscopy. Carbohydr Polym 101:163–170. https://doi.org/10.1016/j.carbpol.2013.09.023

Chen M, Coasne B, Guyer R, Derome D, Carmeliet J (2018) Role of hydrogen bonding in hysteresis observed in sorption-induced swelling of soft nanoporous polymers. Nat Commun 9:3507. https://doi.org/10.1038/s41467-018-05897-9

Cheng Q, Wang J, McNeel J, Jacobson P (2010) Water retention value measurements of cellulosic materials using a centrifuge technique. Bioresources 5(3):1945–1954

Chernova TE, Mikshina PV, Salnikov VV, Ibragimova NN, Sautkina OV, Gorshkova TA (2018) Development of distinct cell wall layers both in primary and secondary phloem fibers of hemp (Cannabis sativa L.). Ind Crop Prod 117:97–109. https://doi.org/10.1016/j.indcrop.2018.02.082

Crônier D, Monties B, Chabbert B (2005) Structure and chemical composition of bast fibers isolated from developing hemp stem. J Agric Food Chem 53:8279–8289. https://doi.org/10.1021/jf051253k

Dai D, Fan M (2010) Characteristic and performance of elementary hemp fibre. Mater Sci Appl 1(6):4. https://doi.org/10.4236/msa.2010.16049

Dai D, Fan M (2011) Investigation of the dislocation of natural fibres by Fourier-transform infrared spectroscopy. Vib Spectrosc 55:300–306. https://doi.org/10.1016/j.vibspec.2010.12.009

Del Masto A, Trivaudey F, Guicheret-Retel V, Placet V, Boubakar L (2017) Nonlinear tensile behaviour of elementary hemp fibres: a numerical investigation of the relationships between 3D geometry and tensile behaviour. J Mater Sci 52:6591–6610. https://doi.org/10.1007/s10853-017-0896-x

Dienes D, Kemény S, Egyházi A, Réczey K (2005) Improving the capability of the Schopper–Riegler freeness measurement. Measurement 38:194–203. https://doi.org/10.1016/j.measurement.2005.07.011

Dumas JBA (1831) Procédés de l’analyse organique. Annales de Chimie et de Physique 247:198–213

Ferreira PJ, Matos S, Figueiredo MM (1999) Size characterization of fibres and fines in hardwood kraft pulps. Part Part Syst Charact 16:20–24. https://doi.org/10.1002/(sici)1521-4117(199905)16:1%3c20:aid-ppsc20%3e3.0.co;2-m

Gallos A, Paes G, Allais F, Beaugrand J (2017) Lignocellulosic fibers: a critical review of the extrusion process for enhancement of the properties of natural fiber composites. RSC Adv 7:34638–34654. https://doi.org/10.1039/c7ra05240e

Gharehkhani S, Sadeghinezhad E, Kazi SN, Yarmand H, Badarudin A, Safaei MR, Zubir MNM (2015) Basic effects of pulp refining on fiber properties—a review. Carbohydr Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

Giummarella N, Henriksson G, Salmén L, Laoko M (2017) On the effect of hemicellulose removal cellulose–lignin interactions. Nord Pulp Pap Res J 32:542–549. https://doi.org/10.3183/NPPRJ-2017-32-04-p542-549

González López CV, García MDCC, Fernández FGA, Bustos CS, Chisti Y, Sevilla JMF (2010) Protein measurements of microalgal and cyanobacterial biomass. Bioresour Technol 101:7587–7591. https://doi.org/10.1016/j.biortech.2010.04.077

Gourier C, Bourmaud A, Le Duigou A, Baley C (2017) Influence of PA11 and PP thermoplastic polymers on recycling stability of unidirectional flax fibre reinforced biocomposites. Polym Degrad Stabil 136:1–9. https://doi.org/10.1016/j.polymdegradstab.2016.12.003

Guerriero G, Mangeot-Peter L, Legay S, Behr M, Lutts S, Siddiqui KS, Hausman J-F (2017) Identification of fasciclin-like arabinogalactan proteins in textile hemp (Cannabis sativa L.): in silico analyses and gene expression patterns in different tissues. BMC Genom 18:741. https://doi.org/10.1186/s12864-017-3970-5

Guessasma S, Beaugrand J (2019) Damage kinetics at the sub-micrometric scale in bast fibers using finite element simulation and high-resolution X-ray micro-tomography. Front Plant Sci. https://doi.org/10.3389/fpls.2019.00194

Guicheret-Retel V, Cisse O, Placet V, Beaugrand J, Pernes M, Boubakar ML (2015) Creep behaviour of single hemp fibres. Part II: influence of loading level, moisture content and moisture variation. J Mater Sci 50:2061–2072. https://doi.org/10.1007/s10853-014-8768-0

Herbaut M, Zoghlami A, Habrant A, Falourd X, Foucat L, Chabbert B, Paës G (2018) Multimodal analysis of pretreated biomass species highlights generic markers of lignocellulose recalcitrance. Biotechnol Biofuels 11:52. https://doi.org/10.1186/s13068-018-1053-8

Hill Callum AS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. J Appl Polym Sci 112:1524–1537. https://doi.org/10.1002/app.29725

Hughes M (2012) Defects in natural fibres: their origin, characteristics and implications for natural fibre-reinforced composites. J Mater Sci 47:599–609. https://doi.org/10.1007/s10853-011-6025-3

Jäger A, Hofstetter K, Buksnowitz C, Gindl-Altmutter W, Konnerth J (2011) Identification of stiffness tensor components of wood cell walls by means of nanoindentation. Compos Part A Appl Sci Manuf 42:2101–2109. https://doi.org/10.1016/j.compositesa.2011.09.020

Komuraiah A, Kumar NS, Prasad BD (2014) Chemical composition of natural fibers and its influence on their mechanical properties. Mech Compos Mater 50:359–376. https://doi.org/10.1007/s11029-014-9422-2

Le Gall M, Davies P, Martin N, Baley C (2018) Recommended flax fibre density values for composite property predictions. Ind Crop Prod 114:52–58. https://doi.org/10.1016/j.indcrop.2018.01.065

Le Moigne N, Otazaghine B, Stéphane C, Angellier-Coussy H, Anne B (2018) Surfaces and interfaces in natural fibre reinforced composites. Springer, New York

Lee KY, Bismarck A (2014) 3-Creating hierarchical structures in cellulosic fibre reinforced polymer composites for advanced performance. In: Hodzic A, Shanks R (eds) Natural fibre composites. Woodhead Publishing, Cambridge, pp 84–102

Lefeuvre A, Bourmaud A, Morvan C, Baley C (2014) Elementary flax fibre tensile properties: correlation between stress–strain behaviour and fibre composition. Ind Crop Prod 52:762–769. https://doi.org/10.1016/j.indcrop.2013.11.043

Lefeuvre A, Duigou AL, Bourmaud A, Kervoelen A, Morvan C, Baley C (2015) Analysis of the role of the main constitutive polysaccharides in the flax fibre mechanical behaviour. Ind Crop Prod 76:1039–1048. https://doi.org/10.1016/j.indcrop.2015.07.062

Legland D, Beaugrand J (2013) Automated clustering of lignocellulosic fibres based on morphometric features and using clustering of variables. Ind Crop Prod 45:253–261. https://doi.org/10.1016/j.indcrop.2012.12.021

Legland D, Arganda Carreras I, Andrey P (2016) MorphoLibJ: integrated library and plugins for mathematical morphology with ImageJ. Bioinformatics 32:3532–3534. https://doi.org/10.1093/bioinformatics/btw413

Liu M, Thygesen A, Summerscales J, Meyer AS (2017) Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: a review. Ind Crop Prod 108:660–683. https://doi.org/10.1016/j.indcrop.2017.07.027

Marrot L, Lefeuvre A, Pontoire B, Bourmaud A, Baley C (2013) Analysis of the hemp fiber mechanical properties and their scattering (Fedora 17). Ind Crop Prod 51:317–327. https://doi.org/10.1016/j.indcrop.2013.09.026

Mazian B, Bergeret A, Benezet J-C, Malhautier L (2018) Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Ind Crop Prod 116:170–181. https://doi.org/10.1016/j.indcrop.2018.02.062

Meng X, Ragauskas AJ (2014) Recent advances in understanding the role of cellulose accessibility in enzymatic hydrolysis of lignocellulosic substrates. Curr Opin Biotechnol 27:150–158. https://doi.org/10.1016/j.copbio.2014.01.014

Mohanty AK, Vivekanandhan S, Pin J-M, Misra M (2018) Composites from renewable and sustainable resources: challenges and innovations. Science 362:536

Morvan C, Andème-Onzighi C, Girault R, Himmelsbach DS, Driouich A, Akin DE (2003) Building flax fibres: more than one brick in the walls. Plant Physiol Biochem 41:935–944. https://doi.org/10.1016/j.plaphy.2003.07.001

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. https://doi.org/10.1557/jmr.1992.1564

Page DH (1989) The beating of chemical pulps—the action and the effects. In: Baker CF, Punton V (eds) Fundamentals of papermaking. 9th Fundamental research symposium notes, vol 1. Wiley, Cambridge, pp 1–38

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos Part A Appl Sci Manuf 83:98–112. https://doi.org/10.1016/j.compositesa.2015.08.038

Placet V, Méteau J, Froehly L, Salut R, Boubakar ML (2014) Investigation of the internal structure of hemp fibres using optical coherence tomography and focused ion beam transverse cutting. J Mater Sci 49:8317–8327. https://doi.org/10.1007/s10853-014-8540-5

Placet V, Day A, Beaugrand J (2017) The influence of unintended field retting on the physicochemical and mechanical properties of industrial hemp bast fibres. J Mater Sci 52:5759–5777. https://doi.org/10.1007/s10853-017-0811-5

Pönni R, Vuorinen T, Kontturi E (2012) Proposed nano-scale coalescence of cellulose in chemical pulp fibers during technical treatments. Bioresources 7(4):6077–6108

Rask M, Madsen B, Sørensen BF, Fife JL, Martyniuk K, Lauridsen EM (2012) In situ observations of microscale damage evolution in unidirectional natural fibre composites. Compos Part A Appl Sci Manuf 43:1639–1649. https://doi.org/10.1016/j.compositesa.2012.02.007

Roux J-C, Bloch J-F, Bordin R, Nortier P (2009) The net normal force per crossing point: a unified concept for the low consistency refining of pulp suspensions. In: 14th Fundamental research symposium: advances in pulp and paper research, FRC, Oxford, pp 51–83

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Shah DU (2013) Developing plant fibre composites for structural applications by optimising composite parameters: a critical review. J Mater Sci 48:6083–6107. https://doi.org/10.1007/s10853-013-7458-7

Shah DU, Nag RK, Clifford MJ (2016) Why do we observe significant differences between measured and ‘back-calculated’ properties of natural fibres? Cellulose 23:1481–1490. https://doi.org/10.1007/s10570-016-0926-x

Sharma B, Shah DU, Beaugrand J, Janeček E-R, Scherman OA, Ramage MH (2018) Chemical composition of processed bamboo for structural applications. Cellulose. https://doi.org/10.1007/s10570-018-1789-0

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Michailof CM, Pilavachi PA, Lappas AA (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrol 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Tanguy M, Bourmaud A, Beaugrand J, Gaudry T, Baley C (2018) Polypropylene reinforcement with flax or jute fibre; influence of microstructure and constituents properties on the performance of composite. Compos Part B Eng 139:64–74. https://doi.org/10.1016/j.compositesb.2017.11.061

Thygesen A, Daniel G, Lilholt H, Thomsen AB (2006a) Hemp fiber microstructure and use of fungal defibration to obtain fibers for composite materials. J Nat Fibers 2:19–37. https://doi.org/10.1300/J395v02n04_02

Thygesen LG, Bilde-Sørensen JB, Hoffmeyer P (2006b) Visualisation of dislocations in hemp fibres: a comparison between scanning electron microscopy (SEM) and polarized light microscopy (PLM). Ind Crop Prod 24:181–185. https://doi.org/10.1016/j.indcrop.2006.03.009

Turner S, Kumar M (2018) Cellulose synthase complex organization and cellulose microfibril structure. Philos Trans A Math Phys Eng Sci 376:2112. https://doi.org/10.1098/rsta.2017.0048

Tze WTY, Wang S, Rials TG, Pharr GM, Kelley SS (2007) Nanoindentation of wood cell walls: continuous stiffness and hardness measurements. Compos Part A Appl Sci Manuf 38:945–953. https://doi.org/10.1016/j.compositesa.2006.06.018

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: Can they replace glass in fibre reinforced plastics? Compos Sci Technol 63:1259–1264. https://doi.org/10.1016/S0266-3538(03)00096-4

Wang B, Sain M, Oksman K (2007) Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl Compos Mater 14:89. https://doi.org/10.1007/s10443-006-9032-9

Washburn EW (1921) The dynamics of capillary flow. Phys Rev 17:273–283. https://doi.org/10.1103/PhysRev.17.273

Westenbroek APH (2000) Extrusion pulping of natural fibers, determination, implementation and verification of constitutive equations required for modelling. Ph.D. Thesis. Wageningen University and Research Centre, Wageningen, 150 p

Xu F, Shi Y-C, Wang D (2013) X-ray scattering studies of lignocellulosic biomass: a review. Carbohydr Polym 94:904–917. https://doi.org/10.1016/j.carbpol.2013.02.008

Yao K, Wu Q, An R, Meng W, Ding M, Li B, Yuan Y (2018) Hydrothermal pretreatment for deconstruction of plant cell wall: part II. Effect on cellulose structure and bioconversion. Aiche J 0. https://doi.org/10.1002/aic.16106

Zhong LX, Fu SY, Zhou XS, Zhan HY (2011) Effect of surface microfibrillation of sisal fibre on the mechanical properties of sisal/aramid fibre hybrid composites. Compos Part A Appl Sci Manuf 42:244–252. https://doi.org/10.1016/j.compositesa.2010.11.010

Acknowledgment

As this project is part of the SINFONI program, the authors would like to thank BPI France for their financial support. The authors would like to thank Bernard Kurek, Anouck Habrant, Olivier Delfosse and François Gaudard from FARE laboratory, for their complementary support. Thanks also to Julien Hubert from Gegenaa for performing the porosimetry experiments. Finally, the authors are grateful to Gilles Bajul from Celodev (Aÿ, France) for his help and scientific discussions on the beating process.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Padovani, J., Legland, D., Pernes, M. et al. Beating of hemp bast fibres: an examination of a hydro-mechanical treatment on chemical, structural, and nanomechanical property evolutions. Cellulose 26, 5665–5683 (2019). https://doi.org/10.1007/s10570-019-02456-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02456-3