Abstract

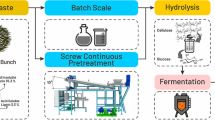

This research aimed to study bioethanol production from Oil Palm Empty Fruit Bunches (OPEFB) with Simultaneous Saccharification and Fermentation (SSF) and Separate Hydrolysis and Fermentation (SHF) by Klyveromyces marxinus. The basic steps for bioethanol production from lignocellulosic biomass are (1) pretreatment for delignification, which is necessary to liberate cellulose and hemicellulose; (2) hydrolysis of cellulose and hemicellulose to generate fermentable sugars; and (3) fermentation of bioethanol from sugars. In step (1) OPEFB was subjected to acid–alkali pretreatment with a dilute acid solution (at substrate loading 12.50%w/v, sulfuric acid concentration 0.2 M, at 121 °C for 53 min) followed by an alkali solution (NaOH 5%w/v, at 121 °C for 20 min), which resulted in 72.10%wt cellulose yield with hemicellulose and lignin yields of 3.24%wt and 17.60%wt, respectively. Then the optimal conditions for ethanol production by SSF process were investigated by Response Surface Methodology. The four manipulated factors were temperature (30–45 °C), substrate loading (5–15% w/v), pH (4–6), and yeast concentration (1–5%v/v), and the maximal 0.281 g/g bioethanol yield was found at 12.24%w/v, pH 4.5, yeast concentration 2.04%v/v, and 36.94 °C. In SHF, hydrolysis and fermentation steps were conducted at the optimal conditions for SSF, giving 0.584 g/g reducing sugar and 0.258 g/g bioethanol yield. The results demonstrate that an acid–alkali pretreatment could remove hemicellulose and lignin from lignocellulosic biomass, increasing cellulose yield, while SSF performed better than SHF with both quicker processing and higher bioethanol concentration.

Similar content being viewed by others

References

Abdul AA, Husin M, Mokhtar A (2002) Preparation of cellulose from oil palm empty fruit bunches via ethanol digestion: effect of acid and alkali catalysts. J Oil Palm Res 14:9–14

AOAC, Arlington (1997) Method 973.18, fiber (acid detergent) and lignin in animal feed. In: Official methods of analysis of AOAC international, 16th edn, ASA-SSA Inc

Barlianti V, Dahnan D, Hendarsyah H, Abimanyu H (2015) Effect of alkaline pretreatment on properties of lignocellulosic oil palm waste. Procedia Chem 16:195–201

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76:965–977

Bujang N, Muhd Rodhi MN, Musa M, Subari F, Idris N, Mohd Makhtar NS, Ku Hamid KH (2013) Effect of dilute sulfuric acid hydrolysis of coconut dregs on chemical and thermal properties, international tribology conference, Malaysia. Procedia Eng 68:372–378

Castro RCA, Roberto IC (2014) Selection of a thermotolerant Kluyveromyces marxianus strain with potential application for cellulosic ethanol production by simultaneous saccharification and fermentation. Appl Biochem Biotechnol 172:1553–1564

Chandel AK, Antunes FAF, Anjos V, Bell MJV, Rodrigues LN, Polikarpov I, Azevedo ERD, Bernardinelli OD, Rosa CA, Pagnocca FC, Silva SSD (2014) Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid–base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels 7:1–17

Chen Y, Sharma-Shivappa RR, Keshwani D, Chen C (2007) Potential of agricultural residues and hay for bioethanol production. Appl Biochem Biotechnol 142:276–290

Chongkhong S (2017) Response surface optimization of ethanol production from banana peels by organic acid hydrolysis and fermentation. Songklanakarin J Sci Technol 39(2):245–252

Correia RTP, Mccue P, Magalhaes MMA, Macedo GR, Shetty K (2004) Production of phenolic antioxidants by the solid-state bioconversion of pineapple waste mixed with soy flour using Rhizopus oligosporus. Process Biochem 39:2167–2172

Cotana F, Cavalaglio G, Gelosia M, Coccia V, Petrozzi A, Ingles D, Pompili E (2015) A comparison between SHF and SSSF processes from cardoon for ethanol production. Ind Crops Prod 69:424–432

Duangwang S, Sangwichien C (2015) Utilization of oil palm empty fruit bunch hydrolysate for ethanol production by Baker’s yeast and loog-pang. Energy Procedia 79:157–162

Duangwang S, Ruengpeerakul T, Cheirsilp B, Yamsaengsung R, Sangwichien C (2016) Pilot-scale steam explosion for xylose production from oil palm empty fruit bunches and the use of xylose for ethanol production. Bioresour Technol 203:252–258

Eklund R, Zacchi G (1995) Simultaneous saccharification and fermentation of steam-pretreated willow. Enzyme Microbial Technol 17:255–259

Folakemi OP, Priscilla JO, Ibiyemi SA (2008) Cellulase production by some fungi cultured on pineapple waste. Nat Sci 6(2):64–79

Gao YL, Ju XR, Jiang HH (2006) Use of response surface methodology to investigate the effect of food constituents on Staphylococcus aureus inactivation by high pressure and mild heat. Process Biochem 41:362–369

Garcia-Aparicio MP, Oliva JM, Manzanares P, Ballesteros M, Ballesteros I, González A, Negro MJ (2011) Second-generation ethanol production from steam exploded barley straw by Kluyveromyces marxianus CECT 10875. Fuel 90:1624–1630

Gundupalli MP, Bhattacharyya D (2008) Ethanol production from acid pretreated food waste hydrolysate using Saccharomyces cerevisiae 74D694 and optimizing the process using response surface methodology. Waste Biomass Valor. https://doi.org/10.1007/s12649-017-0077-9

Hamzah F, Idris A, Shuan KT (2011) Preliminary study on enzymatic hydrolysis of treated oil palm (Elaeis) empty fruit bunches fibre (EFB) by using combination of cellulase and ß 1-4 glucosidase. Biomass Bioenergy 35:1055–1059

Hsu TC, Guo GL, Chen HW, Hwang WS (2010) Effect of dilute acid pretreatment of rice straw on structural properties and enzymatic hydrolysis. Bioresour Technol 101:4907–4913

Ishola MM, Isroi Taherzadeh MJ (2014) Effect of fungal and phosphoric acid pretreatment on ethanol production from oil palm empty fruit bunches (OPEFB). Bioresour Technol 165:9–12

Kadar Z, Szengyel Z, Réczey K (2004) Simultaneous saccharification and fermentation (SSF) of industrial wastes for the production of ethanol. Ind Crops Prod 20:103–110

Kang HW, Kim Y, Kim SW, Choi GW (2012) Cellulosic ethanol production on temperature-shift simultaneous saccharification and fermentation using the thermostable yeast Kluyveromyces marxianus CHY1612. Bioprocess Biosyst Eng 35:115–122

Kim S, Kim CH (2013) Bioethanol production using the sequential acid/alkali-pretreated empty palm fruit bunch fiber. Renew Energy 54:150–155

Kim JK, Oh BR, Shin HJ, Eom CY, Kim SW (2008) Statistical optimization of enzymatic saccharification and ethanol fermentation using foo waste. Process Biochem 43:1308–1312

Kim S, Park JM, Seo JW, Kim CH (2012) Sequential acid-/alkali-pretreatment of empty palm fruit bunch fiber. Bioresour Technol 109:229–233

Kumneadklang S, Larpkiattaworn S, Niyasom C, Thong SO (2015) Bioethanol production from oil palm frond by simultaneous saccharification and fermentation. Energy Procedia 79:784–790

Limtong S, Sringiew C, Yongmanitchai W (2007) Production of fuel ethanol at high temperature from sugarcane juice by a newly isolated Kluyveromyces marxianus. Bioresour Technol 98(17):3367–3374

Loaces I, Schein S, Noya F (2017) Ethanol production by Escherichia coli from Arundo donax biomass under SSF, SHF or CBP process configurations and in situ production of a multifunctional glucanase and xylanase. Bioresour Technol 224:307–313

Martínez PM, Bakker R, Harmsen P, Gruppen H, Kabel M (2015) Importance of acid or alkali concentration on the removal of xylanand lignin for enzymatic cellulose hydrolysis. Ind Crops Prod 64:88–96

Medina JDC, Woiciechowski A, Filho AZ, Nigam PS, Ramos LP, Soccol CR (2016) Steam explosion pretreatment of oil palm empty fruit bunches (EFB) using autocatalytic hydrolysis: a biorefinery approach. Bioresour Technol 199:173–180

Meneses de Barros E, Carvalho VM, Rodrigues THS, Rocha MVP, Gonçalves LRB (2017) Comparison of strategies for the simultaneous saccharification and fermentation of cashew apple bagasse using a thermotolerant Kluyveromyces marxianus to enhance cellulosic ethanol production. Chem Eng J 307:939–947

Merino ST, Cherry J (2007) Progress and challenges in enzyme development for biomass utilization. Adv Biochem Eng Biotechnol 108:95–120

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Ministry of Agriculture and Cooperatives (Thailand). http://www.oae.go.th/download/document_tendency/journal-ofecon2558.pdf. Accessed 20 2015

Mojovic L, Pejin D, Grujic O, Markov S, Penjin J, Rakin M, Vukasinovic M, Nikolic S, Savic D (2009) Progress in the production of bioethanol on starch-based feedstocks. CI&CEQ 15(4):211–226

Montgomery DC (2001) Design and analysis of experiments, 5th edn, Wiley, Arizona State University

Muryanto TE, Abimayu H, Cahyono A, Cahyono ET, Sudiyani Y (2015) Alkaline delignification of oil palm empty fruit bunch using black liquor from pretreatment. Procedia Chem 16:99–105

Nachaiwieng W, Lumyong S, Yoshioka K, Watanabe T, Khanongnuch C (2015) Bioethanol production from rice husk under elevated temperature simultaneous saccharification and fermentation using Kluyveromyces marxianus CK8. Biocatal Agric Biotechnol 4:543–549

Nazir MS, Wahjoedi BA, Yossof AW, Abdulloh MA (2013) Eco-friendly extraction and characterization of cellulose from oil palm empty fruit bunches. BioResources 8:2161–2171

Nguyen QA, Tucker MP, Keller FA, Eddy FP (2000) Two-stage dilute acid pretreatment of softwoods. Appl Biochem Biotechnol 84–86:561–576

Ohgren K, Bura R, Lesnicki G, Saddler J, Zacchi G (2007) A comparison between simultaneous saccharification and fermentation and separate hydrolysis and fermentation using steam-pretreated corn stover. Process Biochem 42:834–839

Pan X, Arato C, Gilkes N, Gregg D, Mabee W, Pye K, Xiao Z, Zhang X, Saddler J (2005) Biorefining of softwoods using ethanol organosolv pulping: preliminary evaluation of process streams for manufacture of fuel-grade ethanol and coproducts. Biotechnol Bioeng 90:473–481

Preechajarn S, Prasertsri P (2014) Thailand biofuels annual. USDA, F. A. S., Ed. Bangkok. EIA. Thailand-Analysis. GAIN report number: TH4057,, Bangkok, 2014. http://www.agrochart.com/en/news/news/290814/thailand-biofuels-annual-aug-2014. Accessed 6 2014

Quintero JA, Montoya MI, Sanchez OJ, Giraldo OH, Cardona CA (2008) Fuel ethanol production from sugarcane and corn: comparative analysis for a Colombian case. Energy 33:385–399

Rani P, Sharma S, garg FC, Raj K, Wati L (2010) Ethanol production from potato flour by Saccharomyces cerevisiae. Indian J Sci Technol 3(7). ISSN: 0974-6846

Renewable Fuels Association (RFA) (2017) Ethanol industry outlook 2017. http://ethanolrfa.org/wp-content/uploads/2017/02/Ethanol-Industry-2017.pdf. Accessed 15 Aug 2017

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37:19–27

Siti SM, Roshanida AR, Norzita N (2013) Pretreatment of oil palm fronds for improving hemicelluloses content for higher recovery of xylose. J Teknol 62:39–42

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Tomas-Pejo E, Oliva JM, Ballesteros M, Olsson L (2008) Comparison of SHF and SSF processes from steam-exploded wheat straw for ethanol production by xylose-fermenting and robust glucose-fermenting Saccharomyces cerevisiae strains. Biotechnol Bioeng 100:1122–1131

Triwahyuni E, Hariyanti S, Dahnum D, Nurdin M, Abimanyu H (2015) Optimization of saccharification and fermentation process in bioethanol production from oil palm fronds. Procedia Chem 16:141–148

Wang Z, Keshwani DR, Redding AP, Cheng JJ (2010) Sodium hydroxide pretreatment and enzymatic hydrolysis of coastal Bermuda grass. Bioresour Technol 101:3583–3585. https://doi.org/10.1016/j.biortech.2009.12.097

Wirawan F, Cheng CL, Kao WC, Lee DJ, Chang JS (2012) Cellulosic ethanol production performance with SSF and SHF processes using immobilized Zymomonas mobilis. Appl Energy 100:19–26

Zakaria MR, Hirata S, Hassan MA (2014) Combined pretreatment using alkaline hydrothermal and ball milling to enhance enzymatic hydrolysis of oil palm mesocarp fiber. Bioresour Technol 169:236–243

Zhou Y, Chen H, Qi F, Zhou X, Liu D (2015) Non-ionic surfactants do not consistently improve the enzymatic hydrolysis of pure cellulose. Bioresour Technol 182:136–143

Zhu Y, Xin F, Zhao Y, Chang Y (2014) An integrative process of bioconversion of oil palm empty fruit bunch fiber to ethanol with on-site cellulase production. Bioprocess Biosyst Eng 37:2317–2324

Acknowledgments

This work was supported by Prince of Songkla University Funding (ENG590710S) and the Graduate School Research Support Funding. Also thanks to the PSU research and development office (RDO) and Assoc. Prof. Seppo Karrila for suggestions to improve the draft manuscript. We gratefully thank the Department of Chemical Engineering, Faculty of Engineering, PSU, for facilities and equipment support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sukhang, S., Choojit, S., Reungpeerakul, T. et al. Bioethanol production from oil palm empty fruit bunch with SSF and SHF processes using Kluyveromyces marxianus yeast. Cellulose 27, 301–314 (2020). https://doi.org/10.1007/s10570-019-02778-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02778-2