Abstract

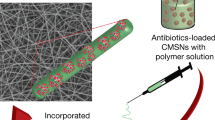

Nanofibrous materials have often been reported as carriers for clinical drugs but face the limitation of releasing the drugs in a burst fashion during use. The aim of this study is to produce composite nanofibrous mats with sustained release, using the broad spectrum antibiotic levofloxacin (LVF) as a model. Sustained release was achieved through two approaches, i.e. by firstly loading LVF into mesoporous silica nanoparticles (MSN) and then incorporating the MSN in the core regions of poly(ɛ-caprolactone) (PCL) nanofibres via core–shell electrospinning. Uniform PCL/LVF nanofibrous mats were also produced as controls. Loading of LVF into the MSN nanopores was confirmed by FTIR, BJH and BET measurements (100 mg LVF/g MSN). After electrospinning, electron microscopy revealed that the MSN were indeed confined in the core regions of the nanofibres. Drug release profiles showed that burst release was decreased from 59 % in the uniform PCL/LVF electrospun mats to 39 % in the core–shell PCL/LVF–MSN mats after 1 day in phosphate buffer at 37 °C, and gradual release in the latter was observed over the next 13 days. Antimicrobial assays showed that the composite electrospun mats were highly effective in killing Escherichia coli even after the mats had been incubated in a phosphate buffer for 14 days while the uniform PCL/LVF mats lost the ability after only 7 days. The results indicate that adsorption of the drug onto MSN and confining them in the core of nanofibres are effective ways of minimizing burst release and achieving sustained release of the drug.

Similar content being viewed by others

References

Langer R (1998) Drug delivery and targeting. Nature 392(6679 Suppl):5–10

De Jong WH, Borm PJ (2008) Drug delivery and nanoparticles: applications and hazards. Int J Nanomed 3(2):133

Jain K (2008) Drug delivery systems—an overview. In: Jain K (ed) Drug delivery systems. Humana Press, Totowa, pp 1–50

Lavan DA, McGuire T, Langer R (2003) Small-scale systems for in vivo drug delivery. Nat Biotechnol 21(10):1184–1191

Ranade VV, Cannon JB (2011) Drug delivery systems. CRC Press, Boca Raton

Ramakrishna S et al (2005) An introduction to electrospinning and nanofibers, vol 90. World Scientific, Singapore

Wang X et al (2002) Electrospinning technology: a novel approach to sensor application. J Macromol Sci Part A 39(10):1251–1258

Huang Z-M et al (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63(15):2223–2253

Kenawy E-R et al (2009) Processing of polymer nanofibers through electrospinning as drug delivery systems. Mater Chem Phys 113(1):296–302

Sill TJ, von Recum HA (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29(13):1989–2006

Zeng J et al (2003) Biodegradable electrospun fibers for drug delivery. J Control Release 92(3):227–231

Kenawy E-R et al (2007) Controlled release of ketoprofen from electrospun poly (vinyl alcohol) nanofibers. Mater Sci Eng A 459(1):390–396

He CL et al (2006) Coaxial electrospun poly (L-lactic acid) ultrafine fibers for sustained drug delivery. J Macromol Sci Part B 45(4):515–524

Zong X et al (2002) Structure and process relationship of electrospun bioabsorbable nanofiber membranes. Polymer 43(16):4403–4412

Xiaoqiang L et al (2009) Fabrication and properties of core-shell structure P (LLA-CL) nanofibers by coaxial electrospinning. J Appl Polym Sci 111(3):1564–1570

Huang ZM et al (2006) Encapsulating drugs in biodegradable ultrafine fibers through co-axial electrospinning. J Biomed Mater Res Part A 77(1):169–179

Song W et al (2013) Coaxial PCL/PVA electrospun nanofibers: osseointegration enhancer and controlled drug release device. Biofabrication 5(3):035006

Yu D et al (2013) Electrospun biphasic drug release polyvinylpyrrolidone/ethyl cellulose core/sheath nanofibers. Acta Biomater 9(3):5665–5672

Qian W et al (2014) Dual drug release electrospun core-shell nanofibers with tunable dose in the second phase. Int J Mol Sci 15(1):774–786

Su Y et al (2011) Encapsulation and controlled release of heparin from electrospun poly (l-lactide-co-ε-caprolactone) nanofibers. J Biomater Sci Polym Ed 22(1–3):165–177

Wang C et al (2010) Biodegradable core/shell fibers by coaxial electrospinning: processing, fiber characterization, and its application in sustained drug release. Macromolecules 43(15):6389–6397

Meng ZX et al (2011) Fabrication, characterization and in vitro drug release behavior of electrospun PLGA/chitosan nanofibrous scaffold. Mater Chem Phys 125(3):606–611

Li L et al (2011) Electrospun poly (ɛ-caprolactone)/silk fibroin core-sheath nanofibers and their potential applications in tissue engineering and drug release. Int J Biol Macromol 49(2):223–232

Tarn D et al (2013) Mesoporous silica nanoparticle nanocarriers: biofunctionality and biocompatibility. Acc Chem Res 46(3):792–801

Liu X (2013) Fabrication of heparinized mesoporous silica nanoparticles as multifunctional drug carriers. J Chem 2013:430459

Grumezescu AM et al (2013) Biocompatible magnetic hollow silica microspheres for drug delivery. Curr Org Chem 17(10):1029–1033

Song B, Wu C, Chang J (2012) Dual drug release from electrospun poly(lactic-co-glycolic acid)/mesoporous silica nanoparticles composite mats with distinct release profiles. Acta Biomater 8(5):1901–1907

Tsai C-H et al (2011) Surfactant-assisted controlled release of hydrophobic drugs using anionic surfactant templated mesoporous silica nanoparticles. Biomaterials 32(26):6234–6244

He Q, Shi J (2011) Mesoporous silica nanoparticle based nano drug delivery systems: synthesis, controlled drug release and delivery, pharmacokinetics and biocompatibility. J Mater Chem 21(16):5845–5855

He Q et al (2009) Intracellular localization and cytotoxicity of spherical mesoporous silica nano- and microparticles. Small 5(23):2722–2729

Yang P, Gai S, Lin J (2012) Functionalized mesoporous silica materials for controlled drug delivery. Chem Soc Rev 41(9):3679–3698

Kortesuo P et al (2000) Silica xerogel as an implantable carrier for controlled drug delivery—evaluation of drug distribution and tissue effects after implantation. Biomaterials 21(2):193–198

Slowing II et al (2008) Mesoporous silica nanoparticles as controlled release drug delivery and gene transfection carriers. Adv Drug Deliv Rev 60(11):1278–1288

Douroumis D (2011) Encapsulation of water insoluble drugs in mesoporous silica nanoparticles using supercritical carbon dioxide. J Nanomed Nanotechnol 2:111

Levine MM (1984) Escherichia coli infections. In: Germanier R (ed) Bacterial vaccines. Academic Press, Inc., New York, pp 187–235

Allen T (1997) Particle size measurement: volume 2: surface area and pore size determination, vol 2. Springer, New York

Zhang Y et al (2010) Spherical mesoporous silica nanoparticles for loading and release of the poorly water-soluble drug telmisartan. J Control Release 145(3):257–263

Shi Y-T et al (2010) The size-controllable synthesis of nanometer-sized mesoporous silica in extremely dilute surfactant solution. Mater Chem Phys 120(1):193–198

Middleton JC, Tipton AJ (2000) Synthetic biodegradable polymers as orthopedic devices. Biomaterials 21(23):2335–2346

Nair LS, Laurencin CT (2007) Biodegradable polymers as biomaterials. Prog Polym Sci 32(8):762–798

Li Z-Z et al (2004) Fabrication of porous hollow silica nanoparticles and their applications in drug release control. J Control Release 98(2):245–254

Kanehata M, Ding B, Shiratori S (2007) Nanoporous ultra-high specific surface inorganic fibres. Nanotechnology 18(31):315602

Park H et al (2012) Fabrication of levofloxacin-loaded nanofibrous scaffolds using coaxial electrospinning. J Pharm Investig 42:1–5

Kim TG, Lee DS, Park TG (2007) Controlled protein release from electrospun biodegradable fiber mesh composed of poly (ɛ-caprolactone) and poly (ethylene oxide). Int J Pharm 338(1):276–283

Pawlak A, Mucha M (2003) Thermogravimetric and FTIR studies of chitosan blends. Thermochim Acta 396(1):153–166

Torres-Giner S et al (2012) Controlled delivery of gentamicin antibiotic from bioactive electrospun polylactide-based ultrathin fibers. Adv Eng Mater 14(4):B112–B122

Nguyen TTT, Chung OH, Park JS (2011) Coaxial electrospun poly(lactic acid)/chitosan (core/shell) composite nanofibers and their antibacterial activity. Carbohydr Polym 86(4):1799–1806

Lu F et al (2011) Effects of amphiphilic PCL–PEG–PCL copolymer addition on 5-fluorouracil release from biodegradable PCL films for stent application. Int J Pharm 419(1):77–84

McDonald PF et al (2010) In vitro degradation and drug release from polymer blends based on poly (dl-lactide), poly (l-lactide-glycolide) and poly (ε-caprolactone). J Mater Sci 45(5):1284–1292. doi:10.1007/s10853-009-4080-9

Acknowledgements

This work has been supported by CSIRO’s Manufacturing flagship. We would also like to thank Chi Huynh for her help with TEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jalvandi, J., White, M., Truong, Y.B. et al. Release and antimicrobial activity of levofloxacin from composite mats of poly(ɛ-caprolactone) and mesoporous silica nanoparticles fabricated by core–shell electrospinning. J Mater Sci 50, 7967–7974 (2015). https://doi.org/10.1007/s10853-015-9361-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9361-x