Abstract

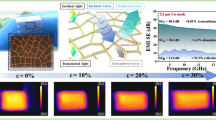

Nowadays, the technical advances call for efficient electromagnetic interference (EMI) shielding of transparent devices which may be subject to data theft. We developed Cu–Ag and Ni–Ag meshes on flexible PET substrate for highly efficiency transparent EMI shielding coating. Cu–Ag and Ni–Ag meshes obtained with galvanic deposition of copper and nickel on thin Ag seed mesh which was made by cracked template method. Coefficients S11, S21 and shielding efficiency (SE) were measured for Cu–Ag and Ni–Ag meshes in X-band (8–12 GHz) and K-band (18–26.5 GHz). 90 s copper deposition increase SE from 23.2 to 43.7 dB at 8 GHz with a transparency of 82.2% and a sheet resistance of 0.25 Ω/sq. The achieved maximum SE was 47.6 dB for Cu–Ag mesh with 67.8% transparency and 41.1 dB for Ni–Ag mesh with 77.8% transparency. Cu–Ag and Ni–Ag meshes have high bending and long-term stability. Minimum bend radius is lower than 100 µm. This effect allows to produce different forms of transparent shielding objects, for example, origami method. Our coatings are the leading among all literary solutions in three-dimensional coordinates: of sheet resistance–optical transmittance–cost of produced.

Graphical abstract

Similar content being viewed by others

References

Guo CF, Ren ZF (2015) Flexible transparent conductors based on metal nanowire networks. Mater Today 18:143–154

Jia LC, Yan DX, Liu XF, Ma RJ, Wu HY, Li ZM (2018) Highly efficient and reliable transparent electromagnetic interference shielding, film. ACS Appl Mater Interfaces 10:11941–11949

Jung J, Lee H, Ha I, Cho H, Kim KK, Kwon J, Won P, Hong S, Ko SH (2017) Highly stretchable and transparent electromagnetic interference shielding film based on silver nanowire percolation network for wearable electronics applications. ACS Appl Mater Interfaces 9:44609–44616

Hu MJ, Gao JF, Dong YC, Li K, Shan GC, Yang SL, Li RKY (2012) Flexible transparent PES/silver nanowires/PET sandwich-structured film for high-efficiency electromagnetic interference shielding. Langmuir 28:7101–7106

Wang RL, Ruan HB (2016) Synthesis of copper nanowires and its application to flexible transparent electrode. J Alloy Compd 656:936–943

Bai XP, Liao SY, Huang Y, Song JA, Liu ZL, Fang MH, Xu CC, Cui Y, Wu H (2017) Continuous draw spinning of extra-long silver submicron fibers with micrometer patterning capability. Nano Lett 17:1883–1891

Wu H, Hu LB, Rowell MW, Kong DS, Cha JJ, McDonough JR, Zhu J, Yang YA, McGehee MD, Cui Y (2010) Electrospun metal nanofiber webs as high-performance transparent electrode. Nano Lett 10:4242–4248

Choi YJ, Kang KM, Lee HS, Park HH (2015) Electromagnetic interference shielding behaviors of Zn-based conducting oxide films prepared by atomic layer deposition. Thin Solid Films 583:226–232

Xu H, Anlage SM, Hu LB, Gruner G (2007) Microwave shielding of transparent and conducting single-walled carbon nanotube films. Appl Phys Lett 90:183119

Hong SK, Kim KY, Kim TY, Kim JH, Park SW, Kim JH, Cho BJ (2012) Electromagnetic interference shielding effectiveness of monolayer graphene. Nanotechnology 23:455704

Zhang HL, Xia Y, Gai JG (2018) Ultrathin active layer for transparent electromagnetic shielding window. ACS Omega 3:2765–2772

Kim BR, Lee HK, Kim E, Lee SH (2010) Intrinsic electromagnetic radiation shielding/absorbing characteristics of polyaniline-coated transparent thin films. Synth Met 160:1838–1842

Xia YJ, Fang J, Li PC, Zhang BM, Yao HY, Chen JS, Ding J, Ouyang JY (2017) Solution-processed highly superparamagnetic and conductive PEDOT:PSS/Fe3O4 nanocomposite films with high transparency and high mechanical flexibility. ACS Appl Mater Interfaces 9:19001–19010

Araki T, Jiu JT, Nogi M, Koga H, Nagao S, Sugahara T, Suganuma K (2014) Low haze transparent electrodes and highly conducting air dried films with ultra-long silver nanowires synthesized by one-step polyol method. Nano Res 7:236–245

Song M, You DS, Lim K, Park S, Jung S, Kim CS, Kim DH, Kim DG, Kim JK, Park J, Kang YC, Heo J, Jin SH, Park JH, Kang JW (2013) Highly efficient and bendable organic solar cells with solution-processed silver nanowire electrodes. Adv Funct Mater 23:4177–4184

Rathmell AR, Wiley BJ (2011) The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates. Adv Mater 23:4798–4803

Kim SJ, Yoon HG, Kim SW (2021) Extremely robust and reliable transparent silver nanowire‐mesh electrode with multifunctional optoelectronic performance through selective laser nanowelding for flexible smart devices. Adv Eng Mater 2001310

Deignan G, Goldthorpe IA (2017) The dependence of silver nanowire stability on network composition and processing parameters. RSC Adv 7:35590–35597

Deng B, Hsu PC, Chen GC, Chandrashekar BN, Liao L, Ayitimuda Z, Wu JX, Guo YF, Lin L, Zhou Y, Aisijiang M, Xie Q, Cui Y, Liu ZF, Peng HL (2015) Roll-to-Roll encapsulation of metal nanowires between graphene and plastic substrate for high-performance flexible transparent electrodes. Nano Lett 15:4206–4213

Ye SR, Stewart IE, Chen ZF, Li B, Rathmell AR, Wiley BJ (2016) How copper nanowires grow and how to control their properties. Accounts Chem Res 49:442–451

Choi JH, Lee KY, Kim SW (2019) Ultra-bendable and durable Graphene-Urethane composite/silver nanowire film for flexible transparent electrodes and electromagnetic-interference shielding. Composite Part B Eng 177:107406

Miao L, Liu GJ, McEleney K, Wang JD (2019) Epoxy-embedded silver nanowire meshes for transparent flexible electrodes. J Mater Sci 54:10355–10370

Lim JW, Lee YT, Pandey R, Yoo TH, Sang BI, Ju BK, Hwang DK, Choi WK (2014) Effect of geometric lattice design on optical/electrical properties of transparent silver grid for organic solar cells. Opt Express 22:26891–26899

Ok JG, Kwak MK, Huard CM, Youn HS, Guo LJ (2013) Photo-roll lithography (PRL) for continuous and scalable patterning with application in flexible electronics. Adv Mater 25:6554–6561

Qi LF, Li J, Zhu CT, Yang Y, Zhao SJ, Song WJ (2016) Realization of a flexible and mechanically robust Ag mesh transparent electrode and its application in a PDLC device. RSC Adv 6:13531–13536

Kang MG, Guo LJ (2007) Nanoimprinted semitransparent metal electrodes and their application in organic light-emitting diodes. Adv Mater 19:1391–1396

Kim HJ, Lee SH, Lee J, Lee ES, Choi JH, Jung JH, Jung JY, Choi DG (2014) High-durable AgNi nanomesh film for a transparent conducting electrode. Small 10:3767–3774

Keith TJ, Matthew WP, Jennifer IH, Keith AR (2009) Predicted and measured EMI shielding effectiveness of a metallic mesh coating on a sapphire window over a broad frequency range Proc.SPIE:7302

Wang WQ, Bai BF, Zhou Q, Ni K, Lin H (2018) Petal-shaped metallic mesh with high electromagnetic shielding efficiency and smoothed uniform diffraction. Opt Mater Express 8:3485–3493

Wang HY, Lu ZG, Tan JB (2016) Generation of uniform diffraction pattern and high EMI shielding performance by metallic mesh composed of ring and rotated sub-ring arrays. Opt Express 24:22989–23000

Han B, Pei K, Huang YL, Zhang XJ, Rong QK, Lin QG, Guo YF, Sun TY, Guo CF, Carnahan D, Giersig M, Wang Y, Gao JW, Ren ZF, Kempa K (2014) Uniform self-forming metallic network as a high-performance transparent conductive electrode. Adv Mater 26:873–877

Kiruthika S, Gupta R, Rao KDM, Chakraborty S, Padmavathy N, Kulkarni GU (2014) Large area solution processed transparent conducting electrode based on highly interconnected Cu wire network. J Mater Chem C 2:2089–2094

Gupta R, Rao KDM, Srivastava K, Kumar A, Kiruthika S, Kulkarni GU (2014) Spray coating of crack templates for the fabrication of transparent conductors and heaters on flat and curved surfaces. ACS Appl Mater Interfaces 6:13688–13696

Voronin AS, Ivanchenko FS, Simunin MM, Shiverskiy AV, Aleksandrovsky AS, Nemtsev IV, Fadeev YV, Karpova DV, Khartov SV (2016) High performance hybrid rGO/Ag quasi-periodic mesh transparent electrodes for flexible electrochromic devices. Appl Surf Sci 364:931–937

Tokuno T, Nogi M, Jiu JT, Sugahara T, Suganuma K (2012) Transparent electrodes fabricated via the self-assembly of silver nanowires using a bubble template. Langmuir 28:9298–9302

Guo CF, Sun TY, Liu QH, Suo ZG, Ren ZF (2014) Highly stretchable and transparent nanomesh electrodes made by grain boundary lithography. Nat Commun 5:3121

Zhu JF, Zhu XD, Hoekstra R, Li L, Xiu FX, Xue M, Zeng BQ, Wang KL (2012) Metallic nanomesh electrodes with controllable optical properties for organic solar cells. Appl Phys Lett 100:143109

Gao TC, Wang BM, Ding B, Lee JK, Leu PW (2014) Uniform and ordered copper nanomeshes by microsphere lithography for transparent electrodes. Nano Lett 14:2105–2110

Han Y, Lin J, Liu YX, Fu H, Ma Y, Jin P, Tan JB (2016) Crackle template based metallic mesh with highly homogeneous light transmission for high-performance transparent EMI shielding. Sci Rep 6:25601

Zoski CG (2007) Handbook of electrochemistry. Elsevier, p 934

Voronin AS, Simunin MM, Fadeev YV, Ivanchenko FS, Karpova DV, Tambasov IA, Khartov SV (2019) Technological basis of the formation of micromesh transparent electrodes by means of a self-organized template and the study of their properties. Tech Phys Lett 45:366–369

Kiruthika S, Rao KDM, Kumar A, Gupta R, Kulkarni GU (2014) Metal wire network based transparent conducting electrodes fabricated using interconnected crackled layer as template. Mater Res Express 1:026301

Periodic Table of Elements and X-ray Energies, https://www.bruker.com/products/x-ray-diffraction-and-elemental-analysis.

Lee HB, Jin WY, Ovhal MM, Kumar N, Kang JW (2019) Flexible transparent conducting electrodes based on metal meshes for organic optoelectronic device applications: a review. J Mater Chem C 7:1087–1110

Kim DH, Park MR, Lee GH (2006) Preparation of high quality ITO films on a plastic substrate using RF magnetron sputtering. Surf Coat Tech 201:927–931

Song JZ, Kulinich SA, Li JH, Liu YL, Zeng HB (2015) A general one-pot strategy for the synthesis of high-performance transparent-conducting-oxide nanocrystal inks for all-solution-processed devices. Angew Chem Int Edit 54:462–466

Hecht DS, Heintz AM, Lee R, Hu LB, Moore B, Cucksey C, Risser S (2011) High conductivity transparent carbon nanotube films deposited from superacid. Nanotechnology 22:075201

Kaskela A, Nasibulin AG, Timmermans MY, Aitchison B, Papadimitratos A, Tian Y, Zhu Z, Jiang H, Brown DP, Zakhidov A, Kauppinen EI (2010) Aerosol-synthesized SWCNT networks with tunable conductivity and transparency by a dry transfer technique. Nano Lett 10:4349–4355

Tsapenko AP, Goldt AE, Shulga E, Popov ZI, Maslakov KI, Anisimov AS, Sorokin PB, Nasibulin AG (2018) Highly conductive and transparent films of HAuCl4-doped single-walled carbon nanotubes for flexible applications. Carbon 130:448–457

Bae S, Kim H, Lee Y, Xu XF, Park JS, Zheng Y, Balakrishnan J, Lei T, Kim HR, Song YI, Kim YJ, Kim KS, Ozyilmaz B, Ahn JH, Hong BH, Iijima S (2010) Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotechnol 5:574–578

Lee SJ, Kim YH, Kim JK, Baik H, Park JH, Lee J, Nam J, Park JH, Lee TW, Yi GR, Cho JH (2014) A roll-to-roll welding process for planarized silver nanowire electrodes. Nanoscale 6:11828–11834

Ye SR, Rathmell AR, Stewart IE, Ha YC, Wilson AR, Chen ZF, Wiley BJ (2014) A rapid synthesis of high aspect ratio copper nanowires for high-performance transparent conducting films. Chem Commun 50:2562–2564

Kim HJ, Kim Y, Jeong JH, Choi JH, Lee J, Choi DG (2015) A cupronickel-based micromesh film for use as a high-performance and low-voltage transparent heater. J Mater Chem A 3:16621–16626

Vishwanath SK, Kim DG, Kim J (2014) Electromagnetic interference shielding effectiveness of invisible metal-mesh prepared by electrohydrodynamic jet printing. Japanese J Appl Phys 53: 05HB11.

Bonninghoff N, Chu JP, Chang CW, Mehretie M, Lai BZ (2018) Preparation and characterization of micron-scale molybdenum metal mesh electrodes. Surf Coat Tech 349:224–232

Wu H, Kong DS, Ruan ZC, Hsu PC, Wang S, Yu ZF, Carney TJ, Hu LB, Fan SH, Cui Y (2013) A transparent electrode based on a metal nanotrough network. Nat Nanotechnol 8:421–425

Kim MH, Joh H, Hong SH, Oh SJ (2019) Coupled Ag nanocrystal-based transparent mesh electrodes for transparent and flexible electro-magnetic interference shielding films. Curr Appl Phys 19:8–13

Rao KDM, Kulkarni GU (2014) A highly crystalline single Au wire network as a high temperature transparent heater. Nanoscale 6:5645–5651

Peng Q, Li SR, Han B, Rong QK, Lu XB, Wang QM, Zeng M, Zhou GF, Liu JM, Kempa K, Gao JW (2016) Colossal figure of merit in transparent-conducting metallic ribbon networks. Adv Mater Technol 1:1600095

Tran DP, Lu HI, Lin CK (2015) Effects of cyclic deformation on conductive characteristics of indium tin oxide thin film on polyethylene terephthalate substrate. Surf & Coat Tech 283:298–310

Park JW, Kim G, Lee SH, Kim EH, Lee GH (2010) The effect of film microstructures on cracking of transparent conductive oxide (TCO) coatings on polymer substrates. Surf Coat Tech 205:915–921

Ahn S, Choe A, Park J, Kim H, Son JG, Lee SS, Park M, Ko H (2015) Directed self-assembly of rhombic carbon nanotube nanomesh films for transparent and stretchable electrodes. J Mater Chem C 3:2319–2325

Lee P, Lee J, Lee H, Yeo J, Hong S, Nam KH, Lee D, Lee SS, Ko SH (2012) Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv Mater 24:3326–3332

An BW, Gwak EJ, Kim K, Kim YC, Jang J, Kim JY, Park JU (2016) Stretchable, Transparent electrodes as wearable heaters using nanotrough networks of metallic glasses with superior mechanical properties and thermal stability. Nano Lett 16:471–478

Zhang CP, Khan A, Cai JX, Liang CW, Liu YJ, Deng JH, Huang SY, Li GX, Li WD (2018) Stretchable transparent electrodes with solution-processed regular metal mesh for an electroluminescent light-emitting film. ACS Appl Mater Interfaces 10:21009–21017

Khan A, Lee S, Jang T, Xiong Z, Zhang CP, Tang JY, Guo LJ, Li WD (2016) High-Performance flexible transparent electrode with an embedded metal mesh fabricated by cost-effective solution process. Small 12:3021–3030

Zhou Y, Azumi R, Shimada S (2019) A highly durable, stretchable, transparent and conductive carbon nanotube–polymeric acid hybrid film. Nanoscale 11:3804–3813

Jiang S, Hou PX, Chen ML, Wang BW, Sun DM, Tang DM, Jin Q, Guo QX, Zhang DD, Du JH, Tai KP, Tan J, Kauppinen EI, Liu C, Cheng HM (2018) Ultrahigh-performance transparent conductive films of carbon-welded isolated single-wall carbon nanotubes. Sci Adv 4:9264

Gunes F, Shin HJ, Biswas C, Han GH, Kim ES, Chae SJ, Choi JY, Lee YH (2010) Layer-by-layer doping of few-layer graphene film. ACS Nano 4:4595–4600

Qiu TF, Luo B, Liang MH, Ning J, Wang B, Li XL, Zhi LJ (2015) Hydrogen reduced graphene oxide/metal grid hybrid film: towards high performance transparent conductive electrode for flexible electrochromic devices. Carbon 81:232–238

Seo KW, Noh YJ, Na SI, Kim HK (2016) Random mesh-like Ag networks prepared via self-assembled Ag nanoparticles for ITO-free flexible organic solar cells. Solar Energy Mater Solar Cells 155:51–59

Geetha S, Kumar KKS, Rao CRK, Vijayan M, Trivedi DC (2009) EMI shielding: methods and materials-a review. J Appl Polym Sci 112:2073–2086

Yang YL, Gupta MC (2005) Novel carbon nanotube-polystyrene foam composites for electromagnetic interference shielding. Nano Lett 5:2131–2134

Shukla V (2019) Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv 1:1640–1671

Han Y, Liu YX, Han L, Lin J, Jin P (2017) High-performance hierarchical graphene/metal-mesh film for optically transparent electromagnetic interference shielding. Carbon 115:34–42

Liu YM, Tan JB (2013) Frequency dependent model of sheet resistance and effect analysis on shielding effectiveness of transparent conductive mesh coatings. Prog Electromagn Res 140:353–368

Maniyara RA, Mkhitaryan VK, Chen TL, Ghosh DS, Pruneri V (2016) An antireflection transparent conductor with ultralow optical loss (<2 %) and electrical resistance (<6 Ω sq−1). Nat Commun 7:13771

Lu ZG, Ma LM, Tan JB, Wang HY, Ding XM (2016) Transparent multi-layer graphene/polyethylene terephthalate structures with excellent microwave absorption and electromagnetic interference shielding performance. Nanoscale 8:16684–16693

Kim DH, Kim Y, Kim JW (2016) Transparent and flexible film for shielding electromagnetic interference. Mater Design 89:703–707

Shen S, Chen SY, Zhang DY, Liu YH (2018) High-performance composite Ag-Ni mesh based flexible transparent conductive film as multifunctional devices. Opt Express 26:27545–27554

Acknowledgements

This work was supported by Russian Foundation for Basic Research project «mol_a» № 18-38-00852 and a scholarship from the President of the Russian Federation SP-2235.2019.1. The sputtering Ag seed mesh and physicochemical analysis of materials was carried out on the equipment of Krasnoyarsk Regional Center of Research Equipment of Federal Research Center «Krasnoyarsk Science Center SB RAS».

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Voronin, A.S., Fadeev, Y.V., Govorun, I.V. et al. Cu–Ag and Ni–Ag meshes based on cracked template as efficient transparent electromagnetic shielding coating with excellent mechanical performance. J Mater Sci 56, 14741–14762 (2021). https://doi.org/10.1007/s10853-021-06206-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06206-4