Abstract

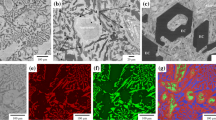

The components made out of hypereutectic high-chromium cast iron (HCCI), featured with high abrasion resistance and hardness, are usually subjected to destabilization treatment before use, to improve their hardness and wear resistance by destabilizing the retained austenite which transforms to martensite. This study investigates the effects of destabilization and tempering heat treatment on the microstructure and mechanical properties of an HCCI with and without modification of primary carbides. For the unmodified HCCI, the destabilization simultaneously increased both hardness and the transverse rupture strength (TRS). Increasing the destabilization temperature from 970 to 1090 °C led to a marginal decrease in hardness and slight increase in TRS. Destabilization at 1090 °C increased the transverse rupture strength (TRS) by 54% compared to the as-cast HCCI without reduction in wear resistance due to the coarsening of the secondary carbides. In addition, tempering within a temperature range from 200 to 280 °C after destabilization at 1090 °C led to a slight decrease in hardness, but an increase in TRS and wear resistance. Further increasing the tempering temperature to 310, 340 and 400 °C did not vary the properties. Tempering at 280 °C after destabilization at 1090 °C enabled more than 85% increase in TRS compared to the as-cast HCCI. The influence of destabilization temperature on the TiB2-modified HCCI is similar to the unmodified alloy. But, tempering after destabilization at 1090 °C decreased both hardness and TRS without significant variation of wear resistance even though a TRS peak was obtained at 310 °C tempering. Hence, to achieve the best performance an optimized heat treatment for the unmodified HCCI is destabilization at 1090 °C followed by tempering at 280 °C. For the TiB2-modified HCCI, tempering is not needed. Rationalizations of the mechanical properties are also discussed in terms of microstructure.

Graphical abstract

Similar content being viewed by others

References

Gahr KHZ, Doane DV (1980) Optimizing fracture toughness and abrasion resistance in white cast irons. Metall Trans A 11(4):613–620

Gahr KHZ, Scholz WG (1980) Fracture toughness of white cast irons. J Metals 32:38–44

Anon, (1978) Cast Iron- A review of recent developments, Eng Mater Des 22(3), 60–65

Bedolla-Jacuinde A, Correa R, Quezada JG, Maldonado C (2005) Effect of titanium on the as-cast microstructure of a 16%chromium white iron. Mater Sci Eng A 398(1–2):297–308

Sare BKAIR (1995) The effect of heat treatment on the gouging abrasion resistance of alloy white cast irons. Metall Mater Trans A 26A:357–370

Dogan GLIÖN, Hawk JA (1995) Abrasion resistance of the columnar zone in high Cr white cast irons. Wear 181–183:342–349

Powell JVBGLF (1996) Secondary carbide precipitation in an 18 wt %Cr-1 wt % Mo white iron. J Mater Sci 31:707–711. https://doi.org/10.1007/BF00367889

Tabrett IRSCP, Ghomashchi MR (1996) Microstructure-property relationships in high chromium white iron alloys. Int Mater Rev 41:59–82

Zhang MX, Kelly PM, Gates JD (2001) The effect of heat treatment on the toughness, hardness and microstructure of low carbon white cast irons. J Mater Sci 36:3865–3875

Wang J, Li C, Liu H, Yang H, Shen B, Gao S, Huang S (2006) The precipitation and transformation of secondary carbides in a high chromium cast iron. Mater Charact 56(1):73–78

Hinckley KFDB, Wuhrer R, Yeung W, Ray A (2008) SEM investigation of heat treated high-chromium cast irons. Mater Forum 32:55–71

Karantzalis AE, Lekatou A, Mavros H (2008) Microstructural modifications of as-cast high-chromium white iron by heat treatment. J Mater Eng Perform 18(2):174–181

Zhi X, Xing J, Gao Y, Fu H, Peng J, Xiao B (2008) Effect of heat treatment on microstructure and mechanical properties of a Ti-bearing hypereutectic high chromium white cast iron. Mater Sci Eng A 487(1–2):171–179

Karantzalis AE, Lekatou A, Diavati E (2009) Effect of destabilization heat treatments on the microstructure of high-chromium cast iron: a microscopy examination approach. J Mater Eng Perform 18(8):1078–1085

Liu Q, Hedström P, Zhang H, Wang Q, Jönsson P, Nakajima GK (2012) Effect of heat treatment on microstructure and mechanical properties of Ti-alloyed hypereutectic high chromium cast iron. ISIJ Int 52(12):2288–2294

Gasan H, Erturk F (2013) Effects of a destabilization heat treatment on the microstructure and abrasive wear behavior of high-chromium white cast iron investigated using different characterization techniques. Metall Mater Trans A 44(11):4993–5005

Lai JP, Pan QL, Wang ZB, Cui HR, Wang XD, Gao ZZ (2017) Effects of destabilization temperature on the microstructure and mechanical properties of high chromium cast iron. J Mater Eng Perform 26(10):4667–4675

Guitar MA, Suárez S, Prat O, Duarte Guigou M, Gari V, Pereira G, Mücklich F (2018) High chromium cast irons: destabilized-subcritical secondary carbide precipitation and its effect on hardness and wear properties. J Mater Eng Perform 27(8):3877–3885

Gelfi M, Pola A, Girelli L, Zacco A, Masotti M, La Vecchia GM (2019) Effect of heat treatment on microstructure and erosion resistance of white cast irons for slurry pumping applications. Wear 428–429:438–448

Sare IR, Arnold BK (1995) The influence of heat treatment on the high-stress abrasion resistance and fracture toughness of alloy white cast irons. Metall Mater Trans A 26:1785–1793

Abdel-Aziz K, El-Shennawy M, Omar AA (2017) Microstructural characteristics and mechanical properties of heat treated high-Cr white cast iron alloys. Int J Appl Eng Res 12:4675–4686

Al-Rubaie KS, Preti O, Pohl M (2016) On the abrasion of heat-treated 2.8 C21Cr1Mo white cast iron. Int J Mater Res 107:815–823

Liu H-H, Wang J, Yang H-S, Shen B-L, Gao S-J, Huang S-J (2006) Effect of cryogenic treatment on property of 14Cr2Mn2V high chromium cast iron subjected to subcritical treatment. J Iron Steel Res Int 13(6):43–48

Yilmaz SO, Teker T (2016) Effect of TiBAl inoculation and heat treatment on microstructure and mechanical properties of hypereutectic high chromium white cast iron. J Alloy Compd 672:324–331

Karantzalis AE, Lekatou A, Kapoglou A, Mavros H, Dracopoulos V (2011) Phase transformations and microstructural observations during subcritical heat treatments of a high-chromium cast iron. J Mater Eng Perform 21(6):1030–1039

Guo Z-H, Xiao F-R, Lu S-L, Li H-Y, Liao B (2016) Effects of heat-treatment on the microstructure and wear resistance of a high-chromium cast iron for rolls. Adv Mater Sci Eng 2016:1–7

Efremenko VG, Wu KM, Chabak YG, Shimizu K, Isayev OB, Kudin VV (2018) Alternative heat treatments for complex-alloyed high-Cr cast iron before machining. Metall Mater Trans A 49(8):3430–3440

Huang JXZ, Zhang A (2006) Investigation of microstructure and impact toughness of semisolid hypereutectic high chromium cast iron prepared by slope cooling body method. J Appl Sci 6:1635–1640

Fu H-G, Wu X-J, Li X-Y, Xing J-D, Lei Y-P, Zhi X-H (2009) Effect of TiC particle additions on structure and properties of hypereutectic high chromium cast iron. J Mater Eng Perform 18(8):1109–1115

Jain A-S, Chang H, Tang X, Hinckley B, Zhang M-X (2020) Refinement of primary carbides in hypereutectic high-chromium cast irons: a review. J Mater Sci 56(2):999–1038. https://doi.org/10.1007/s10853-020-05260-8

Jain AS, Chang H, Zhang MX (2021) Effect of TiB2 addition on microstructure and mechanical properties of a hypereutectic high chromium cast iron. J Mater Sci 56:19047–19059. https://doi.org/10.1007/s10853-021-06429-5

A. International, Standard Test Method for Transverse Rupture Strength of Powder Metallurgy (PM) Specimens, (2016)

Tabrett IRSCP (1998) Effect of high temperature and sub-ambient treatments on the matrix structure and abrasion resistance of a high-chromium white iron. Scripta Mater 38:1747–1753

Babu SS, Bhadeshia HKDH (1995) Diffusion of carbon in substitutionally alloyed austenite. J Mater Sci Lett 14:314–316

Wiengmoon TCA, Pearce JTH (2004) A microstructural study of destabilised 30wt%Cr–2.3wt%C high chromium cast iron. ISIJ Int 44:396–403

Wiengmoon A, Chairuangsri T, Poolthong N, Pearce JTH (2008) Electron microscopy and hardness study of a semi-solid processed 27wt%Cr cast iron. Mater Sci Eng A 480(1–2):333–341

Wang J, Xiong J, Fan H, Yang H-S, Liu H-H, Shen B-L (2009) Effects of high temperature and cryogenic treatment on the microstructure and abrasion resistance of a high chromium cast iron. J Mater Process Technol 209(7):3236–3240

Purba RH, Shimizu K, Kusumoto K, Gaqi Y, Todaka T (2022) Effect of boron addition on three-body abrasive wear characteristics of high chromium based multi-component white cast iron. Mater Chem Phys 275:125232

Pearce JTH (1983) Examination of M7C3 carbides in high chromium cast irons using thin foil transmission electron microscopy. J Mater Sci Lett 2:428–432

Higuera-Cobos FDDOF, Mesa-Grajales DH (2016) Improvement of abrasive wear resistance of the high chromium cast iron ASTM A-532 through thermal treatment cycles. Fac Ing 25:93–103

Guitar MA, Nayak UP, Britz D, Mücklich F (2020) The effect of thermal processing and chemical composition on secondary carbide precipitation and hardness in high-chromium cast irons. Int J Metalcast 14(3):755–765

Kopyciński EGD, Siekaniec D, Szczesny A (2014) Analysis of the high chromium cast iron microstructure after the heat treatment. Arch Foundry Eng 14:43–46

Ortega-Cubillos P, Nannetti-Bernardini PA, Celso-Fredel M, Antonio Campos R, (2015) Wear resistance of high chromium white cast iron for coal grinding rolls, Revista Facultad de Ingeniería Universidad de Antioquia (76)

Maratray F, Poulalion A (1982) Austenite retention in high-chromium white irons. (retroactive coverage). Trans Am Foundrymen’s Soc 90:795–804

Inthidech S, Sricharoenchai P, Matsubara Y (2006) Effect of alloying elements on heat treatment behavior of hypoeutectic high chromium cast iron. Mater Trans 47:72–81

Biner SB (1985) The role of eutectic carbide morphology on the fracture behaviour of high-chromium cast irons-ii. martensitic alloys. Can Metall Q 24:163–167

Biner SB (1985) The role of eutectic carbide morphology on the fracture behavior of high-chromium cast irons-i. austenitic alloys. Can Metall Q 24:155–162

Sare IR (1979) Abrasion resistance and fracture toughness of white cast irons. Metals Technol 6:412–419

Gahr KHZ (1987) Microstructure and wear of materials. Elsevier, Amsterdam

Acknowledgements

The authors are very grateful to Australia Research Council (ARC) Industrial Transformation Training Centre program (IC160100036) for funding support. The authors would also like to thank Australian Microscopy & Microanalysis Research Facility at the Centre for Microscopy and Microanalysis (CMM) at The University of Queensland for the scientific and technical assistance. Abhi-Shek Jain would like to acknowledge the financial support of UQ Research Training Scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, AS., Mustafa, M.I., Sazili, M.I.I.M. et al. Effects of destabilization and tempering on microstructure and mechanical properties of a hypereutectic high-chromium cast iron. J Mater Sci 57, 15581–15597 (2022). https://doi.org/10.1007/s10853-022-07583-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07583-0