Abstract

In this research work we study the influence of Co doping on structural, optical, dielectric and magnetic properties of γ-Fe2O3 (maghemite), which is synthesized by chemical co-precipitation process. The inverse spinel structure of γ-Fe2O3 and Co (5 wt%) doped γ-Fe2O3 nanoparticles is confirmed by X-ray Diffraction (XRD), Fourier transform Infrared and Raman techniques. The average particle size is calculated, using Transmission electron microscope is about 10.83 ± 1.83 nm and 14.76 ± 2.41 nm for undoped and Co doped maghemite nanoparticles respectively, also confirmed by XRD measurements. The introduction of Co to γ-Fe2O3 nanoparticles improves crystallization. The dielectric measurement (ϵr, tanδ) gives the deep insight of the microstructure of the samples. The dielectric constant (ϵr) reduced in case of Co doped γ-Fe2O3 nanoparticles, which is more likely due to reduction in defect density and enhancement in grain size and crystallization by introduction of Co into γ-Fe2O3 lattice. The enhancement in ac conductivity (σac) in case of Co doped γ-Fe2O3 is due to fast hopping process between Fe2+/Fe3+ in undoped maghemite, increase in conducting grain volume and charge density (detached from traps + conducting charge carriers) in Fe2+/Fe3+ and Co2+/Co3+ in doped maghemite nanoparticles. The blocking temperature shifted from 62 to 88 K, which is most possibly due to increased grain size, enhanced interaction of dipole–dipole and probably increase the potential barrier for thermal instabilities. Both samples show superparamagnetic characteristic and the saturation magnetization (Ms) is increased from 30 to 35 emu/g in case of Co doped maghemite nanoparticles. This is due to Co and lattice spins parallel alignment in maghemite nanoparticles.

Similar content being viewed by others

1 Introduction

Maghemite nanoparticles (γ-Fe2O3) are focus of the research groups due to their applications including magnetic separation, drug delivery, hyperthermia, Magnetic Resonance imaging (MRI) and information storage [1,2,3]. Besides these applications, maghemite nanoparticles are also known for their usage in magnetic storage industry [4,5,6,7,8]. γ-Fe2O3 nanoparticles have Inverse spinel structure having the formula (\({\text{Fe}}_{8}^{\text{III}}\))A [\({\text{Fe}}_{40/3}^{\text{III}}\)⊡8/3]BO32, here A, B and ⊡ represent tetrahedral, octahedral sites and vacancies, respectively [9, 10]. The vacancies are distributed with different degree of order–disorder and confined to the octahedral sites. γ-Fe2O3 has ferrimagnetic ordering and notable saturation magnetization (Ms) at room temperature [2, 11]. Maghemite nanoparticles having size less than 20 nm show super paramagnetic behaviour at room temperature. When the particles size reduces to 10 nm, the disorder in the cations along with randomly oriented (disordered) surface spins layer around the particle, decreases saturation magnetization and coercivity. Therefore, it is very important to employ and develop different techniques to control the size and surface engineering of maghemite nanoparticles. Reduction in size causes large surface to volume ratio and hence in nanostructure surface plays the dominant role. But reduction in size of maghemite nanoparticles beyond a certain limit is not favorable, because it causes problems of reduction in saturation magnetization and coercivity and limiting their applications. In order to control the saturation magnetization and coercivity of very small sized maghemite nanoparticles, methods of doping and coating are used. So maghemite nanoparticles are either doped with appropriate dopants or their surface is coated with suitable surfactant to obtain small sized nanoparticles with almost no decrease in saturation magnetization and coercivity [12].

Besides magnetic properties, dielectric properties especially the conductivity, dielectric loss and dielectric constant of maghemite nanoparticles are very important for the applications of microelectronic devices. Information about the conduction (frequency dependent ac conductivity) can be carried out from the dielectric properties [13, 14].

Because of many different chemical and physical properties, different methods could be used for synthesis of nanostructured maghemite. The γ-Fe2O3 nanoparticles synthesized by ceramic method are non-uniform, larger in size and have low density. In order to synthesize homogeneous and ultra-fine grained ferrites co-precipitation, hydrothermal process and wet chemical methods are used [15].

The properties of γ-Fe2O3 nanoparticles changes with type and concentration of dopants. Among various dopants, Cobalt (Co) is selected because Co doped γ-Fe2O3 nanoparticles shows high chemical stability, better mechanical hardness, remarkably greater electrical resistivity, and large permeability at higher frequencies [16]. The coercivity (Hc) in Cobalt-doped γ-Fe2O3 can be enhanced because it is the function of the anisotropy and Cobalt ions orientation in the γ-Fe2O3 lattice. Mainly it is considered due to effective uniaxial anisotropy instead of magneto-crystalline anisotropy in Cobalt-doped γ-Fe2O3. The crystalline anisotropy could be different when Cobalt ions are doped into the lattice in comparison to that of the surface doped particles. The anisotropy varies with particle size, concentration, distribution of dopant (Cobalt ions) and the nature of surface of particles [7, 17, 18]. In spite of reported literature related to Cobalt-doped γ-Fe2O3 [19,20,21,22] both in bulk and at nanoscale [23, 24], less attention is paid to its dielectric and magnetic behaviors.

The present work describes the variation in optical, dielectric and magnetic properties of Cobalt-doped γ-Fe2O3 nanoparticles synthesized by co-precipitation method. Furthermore, variation in structural, optical, dielectric and magnetic properties of Co doped γ-Fe2O3 nanoparticles is reported in a more clear and systematic way.

2 Experimental details

2.1 Materials

Ferrous chloride tetra-hydrate (FeCl2·4H2O) with purity above 99%, Ferric chloride hexa-hydrate (FeCl3·6H2O) with purity above 98% and Cobalt chloride (CoCl2) with purity above 98% was purchased from Daejung. Sodium hydroxide (NaOH) with purity above 98% was purchased from Sigma-Aldrich. All reagents have been used directly without any further purification. For nanoparticles synthesis, distilled water were used.

2.2 Synthesis

The nanoparticles of un-doped and cobalt doped maghemite were synthesized by co-precipitation method. For preparing pure maghemite nanoparticles 0.228 M FeCl2·4H2O was used to mix in 25 ml of deionized water, and 0.444 M FeCl3·6H2O was added in 25 ml of distilled water. Then, both solutions (FeCl2·4H2O and FeCl3·6H2O) were added at room temperature (Fe2+/Fe3+=1/2) and stirred for about 15 min. 50 ml of the mixture was added in the form of drops through the burette into 450 ml of 1 M NaOH solution under stirring for about 30 min with constant drop rate. Precipitates were separated by applying a magnetic field, and washed (6 times) by centrifugation at 6000 rpm with distilled water. The precipitates dried at 60 °C. The precursor decomposed into maghemite (γ-Fe2O3) by annealing it in furnace at 250 °C for 3 h in air.

For the preparation of Cobalt doped maghemite nanoparticles, 5 wt% of Cobalt chloride (CoCl2) was used as cobalt source. The 5 wt% of Cobalt chloride (CoCl2) was added to ferrite solution in order to obtain γ-Fe(2−x)CoxO3 (x = 0.05) nanoparticles and rest of the process is same as that of undoped maghemite nanoparticles.

2.3 Material measurements

The samples after synthesis were characterized by X-ray diffraction (XRD) using XRD X-ray diffractometer (PANalytical Empyrean-Expert-3 powder), operating at 30 kV and 40 mA with Cu Kα radiation of wavelength λ = 0.15418 nm at 2θ values in the range between 20° and 70°. The morphologies of the sample was investigated by a JSM-5910, JEOL (Japan) scanning electron microscope (SEM) with an accelerating potential of 20 kV. For transmission electron microscopy, TEM FEI F20 (USA) system was used to record the images of the sample. The chemical composition was investigated, using an energy dispersive X-ray (EDS) spectroscopy SEM–EDX (INCA200/Oxford instruments, UK) coupled to SEM. The Fourier transform infrared spectroscopy (FTIR) was used for different vibrational modes in the sample. The dielectric behavior and frequency dependent conductivity were investigated on centered Gold electrode pellet with a typical Impedance analyzer (Agilent 4292) in frequency range between 15 and 40 MHz. A Quantum Design magnetic properties measurement system (MPMS) was used to measure the Dc magnetization (M(H) at room temperature.

3 Results and discussion

3.1 XRD analysis of maghemite

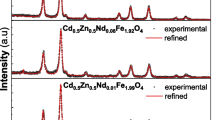

Figure 1 shows the XRD patterns of un-doped maghemite (γ-Fe2O3) and Cobalt-doped maghemite nanoparticles. Six main diffraction peaks were observed at 2θ = 30°, 35.4°, 43.6°, 52.8°, 58.4°, 64°, which correspond to the planes (200), (311), (400), (422), (511) and (440) respectively, and are in agreement with the card (JCPDS No. 22-1086). Both patterns excluded the formation of impurity phases; the only phase present is that of maghemite nanoparticles.

The XRD peaks in case of Co doped maghemite nanoparticles are shifted slightly towards smaller angles as compared to undoped sample. This indicates that Co replaced Fe in maghemite lattice. Lattice parameters are calculated from XRD patterns for both samples. The lattice parameters for un-doped and Co doped maghemite are 8.365 Å and 8.496 Å respectively. Increase in lattice parameters with substitution of Co is observed. The increase in lattice parameters and shift of peaks are due to the large ionic radii of Co2+ as compared to Fe3+ [25]. The dislocation density given in Table 1 is decreased in case of Co doped Maghemite indicating the improvement in crystallization with Co doping [26]. The increase in lattice constants, lattice volume and crystallite size are the indication of effective substitution of Co in maghemite to replace Fe. The average crystallite size of the un-doped and Cobalt-doped maghemite nanoparticles were calculated by using Debye–Scherer’s formula [27].

where D is the size of the crystallite, λ is the wavelength of the X-rays, β is full width at half maximum (FWHM) of the diffraction peak and θ is the angle of incidence. The average crystallite sizes of the un-doped and Cobalt-doped nanoparticles calculated are 9.45 ± 1.29 and 15.28 ± 5.51 nm respectively. Different parameters like crystallite size, lattice parameters, d-spacing, lattice volume, sample density, X-ray density, porosity and specific surface area are determined from XRD and tabulated in Table 1.

3.2 FTIR spectra analysis

FTIR is used to investigate the composition and quality of the material. The spectra of the un-doped maghemite and Cobalt-doped maghemite are depicted in Fig. 2. FTIR is used in the frequency range from 400 to 4000 cm−1. The peaks near to 480 and 580 cm−1 are assigned to Fe–O stretching vibrational mode in maghemite. The band at 865 cm−1 is observed only in Cobalt-doped maghemite, which is attributed to Co–O [28, 29]. The broad absorption band is due to O–H stretching vibrational mode of H2O absorption at γ-Fe2O3 nanoparticles surface around 3415 cm−1 [30]. FTIR analysis confirmed the formation of maghemite and Co doped maghemite nanoparticles.

3.3 SEM analysis

The SEM micrographs of un-doped and Cobalt-doped maghemite are given in Fig. 3a, b. The SEM image of un-doped Maghemite shows a rough surface consisting of broken pieces of spherical shape morphology. SEM micrograph of Cobalt-doped Maghemite shows that surface roughness is enhanced along agglomeration and the particles are of irregular shape. The morphology of the particles changed with Co doping.

3.4 EDX analysis

Figure 3c–d shows the energy dispersive spectra of pure Maghemite and Cobalt-doped maghemite respectively. Figure 3c, d show that the sample contains only Fe and O in case undoped sample and Fe, Co and O in cased of doped sample excluding the presence of impurity phases. Pt appears due to sputtered coating of the samples for SEM. In case of doped sample the Fe content reduced from 67.54 to 61.21 wt% with addition of Co, which confirms that Co replaced Fe in maghemite lattice.

3.5 Raman spectra analysis

The Raman spectra of the un-doped maghemite and Cobalt-doped maghemite are shown in Fig. 4. The Raman spectra depicted in Fig. 4 is consistent with the Raman spectra of maghemite nanoparticles reported, somewhere else in Table 2 [31]. The Maghemite nanoparticles having three Raman active phonon modes T2g at 360.16 cm−1, Eg at 503.83 cm−1, and A1g at 703.45 cm−1 In Cobalt-doped maghemite spectra the peaks shifted to lower wavelengths, which is most probably due to tensile stress developed in the sample with incorporation of Co2+ ions. Furthermore, the increase in intensities is the indication that Cobalt is incorporated in maghemite and its crystallization is improved as compared to undoped sample.

3.6 TEM and size distribution

Figure 5a, b show the TEM images of maghemite and Co doped maghemite nanoparticles. Both the samples show spherical shaped nanoparticles. The particle size distribution of the undoped maghemite nanoparticles lies between 8 and 14 nm having mean particle size of 10.83 ± 1.76 nm as shown in Fig. 5c. The substitution of Cobalt (Co) in maghemite lattice increases the particle size. The size distribution of Co doped maghemite nanoparticles lies between 12 and 17 nm with an average particle size of 14.76 ± 2.41 nm as shown in Fig. 5d. TEM and XRD results agree firmly well.

3.7 Dielectric constant (εr)

The variation of εr with frequencies for the Cobalt-doped and un-doped maghemite nanoparticles are presented in Fig. 6. The values of εr decreases with increasing frequencies as shown by the dispersion behavior. At low frequencies the charge carriers in the material align themselves along the field till they reach the grain boundaries, where the charge carriers are accumulated to produce large polarization and hence the dielectric constant increases. The dielectric behavior can be interpreted by the following three theories.

- 1.

Maxwell–Wagner theory (MWT) of polarization, according to which at low frequencies grain boundaries (Resistive) are responsible for the enhancement of dielectric constant [32].

- 2.

The hopping model (HM) describes that at low frequencies hopping of charge carriers is responsible for the increase in dielectric constant. At low frequencies the electrons takes longer time to reach grain boundaries, where all the charge carries are assembled (due to resistive nature of grain boundaries) and hence large polarization is induced.

- 3.

Hopping of charge carriers and Rezlescue model, according to which carriers can be exchanged between Co2+/Co3+ and Fe2+/Fe3+ ions, that transfer between the substituted metallic ions to produce polarization [33, 34].

However at higher frequencies, charge carriers lag behind the applied electric field (field switches direction so fast that charge carriers cannot follow it), which ultimately reduce polarization and thus dielectric constant becomes frequency independent. At lower frequencies the observed εr is maximum for un-doped maghemite nanoparticles due to small particle size having large surface area, which can accommodate large number of defects. These defects trap conduction charge carriers to contribute rotational direction polarization (RDP) and space charge polarization (SCP) and resulting in large εr.

3.8 Dielectric loss tangent (tan δ)

The dielectric loss is the measure of dissipated electromagnetic energy within the material, when an alternating (ac) electromagnetic field is applied. The dielectric loss takes place when the polarization switches direction in the applied ac field. The materials having large defect density (impurities and imperfections in the crystal etc.) have large dielectric loss. The variation of dielectric loss tangent with frequency at room temperature for un-doped and Cobalt doped Maghemite nanoparticles are shown in Fig. 7. The dielectric loss for both samples is larger at lower frequencies and decreases with increasing frequencies. In the low frequency region (high resistivity) more energy is essential for carriers exchange between Fe2+/Fe3+ ions and hence the loss is high. In the region of high frequency (low resistivity) a small energy is needed for electron transfer between the two Fe ions. The loss in dielectric of a material is given by the relation [35]:

here σ is the ac conductivity, ω the angular frequency.

According to Eq. (2) \(\varepsilon_{r}\) and tanδ are inversely related as observed in Figs. 6, 7 and 8. With the increase in ω, \(\varepsilon_{r}\) decreases while σ increases. The increase of tanδ before the occurrence of relaxation peak is attributed to the rapid decrease \(\varepsilon_{r}\) and abrupt increase of σ. Anomalous dielectric behavior or relaxation peaks are achieved for both the samples. This behavior can be interpreted by Rezlescu model [33, 34]. According to this model, the peak behavior is observed when the hopping frequency of charge carriers between the Fe2+/Fe3+ and Co2+/Co3+ ions matches the frequency of external applied field.

here \(\upomega = 2\pi f_{max}\) and \(\tau\) is the relaxation time.

So the maxima is observed when the jumping or hopping frequency of electrons between Fe2+/Fe3+ and Co2+/Co3+ is equal to the frequency of the field. The relaxation peak enhanced with Cobalt doping is due to enhancement in hopping of charge carriers with contribution from Co2+/Co3+ ions along with Fe2+/Fe3+ ions. Also with Cobalt doping the thermally dissociated oxygen causes to increase the number of vacancies [36]. Thus the relaxation peak shifted slightly to higher frequency and its intensity increased. Furthermore, the multiple relaxation peaks in case of Co doped maghemite nanoparticles are most probably due to change in activation energy of conduction process.

3.9 Conductivity

Figure 8 depicts the frequency dependence of ac conductivity at room temperature of un-doped and Cobalt-doped Maghemite. At low frequency the graph shows almost frequency independent behavior, while strong frequency dependence at higher frequency region. According to Pollack, if the hopping process takes place then conductivity increases with frequency [37]. Thus from the Fig. 8 it is clear that, in our samples the electrical conduction is due to the hopping of carriers between the ions (Co2+/Co3+ and Fe2+/Fe3+) which are randomly distributive. The total conduction is given by:

The first term in Eq. (4) doesn’t depends on frequency (dc conductivity) and represents conduction band. The second term depends on frequency and refers to hopping conduction which is purely ac conductivity. The below Eq. (5) shows that the ac conductivity obey power law [35]:

here B and n are constants which depends on temperature and composition, n has no dimension and B has the unit of electrical conductivity. In ferrites, hopping of charge carriers between Fe2+/Fe3+ ions is responsible for the conduction. The applied frequency acts as a pump force and hence increases the ac conductivity. This enables transferring of charge carriers between the different localized states as well as some trapped charges become free from traps (defects, vacancies) and contribute to the conduction of the material simultaneously. Figure 8 clearly indicates that the conductivity of Cobalt doped Maghemite is greater than the un-doped Maghemite. The increase in conductivity with cobalt doping is due to the reduction in surface area, decreases defects, increase in conducting volume of the grains (grain growth), which reduces number of resistive grain boundaries and also the contribution of fast hopping of carriers between Co3+/Co2+ and Fe2+/Fe3+.

The exponent “n” can be calculated by plotting lnσ against lnω using Eq. (5) [38], representing straight lines and having slope equal to exponent n. Figure 9 shows ln (σ) versus ln (ω) graph. The slops of the graphs equal to the exponent n. The reported values for n are between 0 and 1. For dc conduction the value of n = 0 while for frequency dependent conduction (hopping) the magnitude of n > 0. In current work the values of “n” for both samples is 0 < n < 1. Thus in our samples the conduction takes place due to hopping process.

3.10 Magnetic properties

Magnetic properties of the un-doped Maghemite and Cobalt doped samples are obtained from field-cooled (FC) and zero field-cooled (ZFC) magnetization M (T), indicated in Fig. 10. In case of ZFC, the magnetization data of the samples were recorded until it is cooled down up to 5 K in the absence of external applied field. The same procedure is used in case of FC also, until the samples were cooled up to 5 K in the presence of 1 kOe external applied field. We observed an increase in both magnetization and blocking temperature TB of Cobalt doped un-doped sample. The blocking temperature TB is shifted to higher temperatures due to the size effect of their particle (already confirmed from XRD) of Cobalt doped maghemite nanoparticles and enhanced inter-particles dipole–dipole interactions resulting to increase the energy barrier due to increased thermal fluctuations. In the current work the value of TB is enhanced from 62 to 88 K for un-doped and Cobalt doped maghemite nanoparticles, respectively. The maximum (peak) of the ZFC curve for Cobalt doped particles is comparatively sharp as compared to the ZFC curve of un-doped maghemite nanoparticles and it shows the wide size distribution of particles.

3.11 Magnetization

Figure 11 shows the M–H plots for un-doped Maghemite and Cobalt doped Maghemite samples at room temperature. Both samples show superparamagnetic characteristics at room temperature. The saturation magnetization for un-doped and Cobalt doped samples are 30 and 35.8 emu/g, respectively. This variation in magnetization with Cobalt incorporation in maghemite results due to strong interactions of Co and lattice spins. The spin–lattice contact aligns the Cobalt spins parallel to the lattice. The magnetic behavior of Cobalt doped Maghemite strongly depends on the dissemination of Co2+ ions in the spinel structure. The distributions of Co2+ ions are expecting to be on both the octahedral site (B) and tetrahedral site (A) in the spinel structure of Maghemite. The homogeneity in embodiment of the Co2+ ions results to elevate the magnetization of the nanoparticles caused due to the uniaxial anisotropy along the direction of magnetization [7].

4 Conclusion

Maghemite and 5 wt% Co doped maghemite nanoparticles are prepared by chemical precipitation method. XRD confirmed the inverse spinel structure of undoped and co doped maghemite nanoparticles. The mean particle size is increased from 10.83 ± 1.83 nm and 14.76 ± 2.41 nm with Co doping. EDX confirmed the presence of Fe and O for maghemite and Fe, O and Co for doped samples and ruled out the possibilities of impurities. FTIR and Raman spectra agree with XRD. Dielectric measurements revealed that Co doping improved the crystallization, volume of conducting grains has grown resulting in reduced number of grain boundaries and hence dielectric constant. In dielectric loss the relaxation peaks are observed, whose intensity enhanced with incorporation of cobalt in maghemite nanoparticles. Ac conductivity increased with Co doping which is due to fast hopping process between Fe2+/Fe3+ and Co2+/Co3+ ions, increase in volume of conducting grains and increase in charge density (conduction charge carriers and charge carriers from traps). The shift in blocking temperature towards larger values of temperature with Co doping is most probably due to increased dipole–dipole interactions and increase in potential barrier with enhancement in thermal fluctuations. The increased magnetization in Co doped maghemite nanoparticles is due to incorporation of Co on both tetrahedral and octahedral sites and interaction of Co and lattice spins to favor parallel alignment. The Co doped maghemite nanoparticles are potential candidates to be used in the fields of optoeletronics, diluted magnetic semiconductors and high frequency dielectrics.

Change history

20 December 2019

The original version of this article unfortunately published with few errors in Figure 1 and Table 1 which was reported to the Editorial Office. This has been corrected by publishing this Erratum.

References

S. Sun, Recent advances in chemical synthesis, self-assembly, and applications of FePt nanoparticles. Adv. Mater. 18, 393–403 (2006)

P. Tartaj, M. del Puerto Morales, S. Veintemillas-Verdaguer, T. González-Carreño, C.J. Serna, The preparation of magnetic nanoparticles for applications in biomedicine. J. Phys. D Appl. Phys. 36, R182 (2003)

Q.A. Pankhurst, J. Connolly, S. Jones, J. Dobson, Applications of magnetic nanoparticles in biomedicine. J. Phys. D Appl. Phys. 36, R167 (2003)

Y.S. Kang, D.K. Lee, C.S. Lee, P. Stroeve, In situ observation of domain structure in monolayers of arachidic acid/γ-Fe2O3 nanoparticle complexes at the air/water interface. J. Phys. Chem. B 106, 9341–9346 (2002)

A. Dyal et al., Activity of Candida rugosa lipase immobilized on γ-Fe2O3 magnetic nanoparticles. J. Am. Chem. Soc. 125, 1684–1685 (2003)

K. Woo, H.J. Lee, J.P. Ahn, Y.S. Park, Sol–gel mediated synthesis of Fe2O3 nanorods. Adv. Mater. 15, 1761–1764 (2003)

S. Chakrabarti, S. Mandal, S. Chaudhuri, Cobalt doped γ-Fe2O3 nanoparticles: synthesis and magnetic properties. Nanotechnology 16, 506 (2005)

A. Ngo, P. Bonville, M. Pileni, Spin canting and size effects in nanoparticles of nonstoichiometric cobalt ferrite. J. Appl. Phys. 89, 3370–3376 (2001)

X. Battle, A. Labarta, Finite-size effects in fine particles: magnetic and transport properties. J. Phys. D Appl. Phys. 35(6), R15–R42 (2002)

K.-J. Lee et al., Protective effect of maghemite nanoparticles on ultraviolet-induced photo-damage in human skin fibroblasts. Nanotechnology 18, 465201 (2007)

Zulfiqar, R. Khan, M.U. Rahman, Z. Iqbal, Variation of structural, dielectric and magnetic properties of PVP coated γ-Fe2O3 nanoparticles. J. Mater. Sci. Mater. Electron. 27, 12490–12498 (2016)

G. Goya, T. Berquo, F. Fonseca, M. Morales, Static and dynamic magnetic properties of spherical magnetite nanoparticles. J. Appl. Phys. 94, 3520–3528 (2003)

Zulfiqar, M.U. Rahman, M. Usman, S.K. Hasanain, A. Ullah, I.W. Kim, Static magnetic properties of Maghemite nanoparticles. J. Korean Phys. Soc. 65, 1925–1929 (2014)

P. Sahay, R. Mishra, S. Pandey, S. Jha, M. Shamsuddin, Structural, dielectric and photoluminescence properties of co-precipitated Zn-doped SnO2 nanoparticles. Curr. Appl. Phys. 13, 479–486 (2013)

A. Sheikh, V. Mathe, Anomalous electrical properties of nanocrystalline Ni–Zn ferrite. J. Mater. Sci. 43, 2018–2025 (2008)

Y. Yamazaki, M. Satou, High frequency conductivity in cobalt–iron ferrite. Jpn. J. Appl. Phys. 12, 998 (1973)

T. Orth, M. Möller, J. Pelzl, W. Schmitt, B. Köhler, Characterisation of the anisotropy behaviour of different cobalt modified γ-Fe2O3 tapes. J. Magn. Magn. Mater. 145, 243–254 (1995)

E. Koster, Magnetic anisotropy of cobalt-doped gamma ferric oxide. IEEE Trans. Magn. 8, 428–429 (1972)

T. Tsuji, K. Ando, K. Naito, Y. Matsui, Coercivity and Mössbauer spectroscopy studies of cobalt-adsorbed γ-Fe2O3. J. Appl. Phys. 69, 4472–4474 (1991)

H. Sun, J. Coey, Y. Otani, D. Hurley, Magnetic properties of a new series of rare-earth iron nitrides: R2Fe17Ny (y approximately 2.6). J. Phys. Condens. Matter 2, 6465 (1990)

Y. Fukumoto, K. Matsumoto, Y. Matsui, Influence of IIA metals (Mg, Ca, Sr, Ba) on the Co modification of γ-Fe2O3 particles. J. Appl. Phys. 69, 4469–4471 (1991)

F. Spada, F. Parker, A. Berkowitz, T. Cox, Hc enhancement of Co-adsorbed γ-Fe2O3 particles via surface treatment with sodium polyphosphate. J. Appl. Phys. 75, 5562–5564 (1994)

A. Ngo, P. Bonville, M. Pileni, Nanoparticles of: synthesis and superparamagnetic properties. Eur. Phys. J. B Condens. Matter Complex Syst. 9, 583–592 (1999)

A. Giri, E. Kirkpatrick, P. Moongkhamklang, S. Majetich, V. Harris, Photomagnetism and structure in cobalt ferrite nanoparticles. Appl. Phys. Lett. 80, 2341–2343 (2002)

S. Singhal, T. Namgyal, S. Bansal, K. Chandra, Effect of Zn substitution on the magnetic properties of cobalt ferrite nano particles prepared via sol–gel route. J. Electromagn. Anal. Appl. 2, 376 (2010)

Zulfiqar, S. Afzal, R. Khan, T. Zeb, M.U. Rahman, Burhanullah, S. Ali, G. Khan, Z. ur Rahman, A. Hussain, Structural, optical, dielectric and magnetic properties of PVP coated magnetite (Fe3O4) nanoparticles. J. Mater. Sci. Mater. Electron. 29, 20040–20050 (2018).

B.D. Cullity, Elements of X-ray Diffraction (Prentice Hall, Upper Saddle River, 2001)

M. Ivashchenko, I. Buryk, B. Khudenko, in International Conference on Nanomaterials: Application & Properties (NAP) (IEEE, 2016), pp. 01NTF12-01-01NTF12-04

S. Anjum, R. Tufail, K. Rashid, R. Zia, S. Riaz, Effect of cobalt doping on crystallinity, stability, magnetic and optical properties of magnetic iron oxide nano-particles. J. Magn. Magn. Mater. 432, 198–207 (2017)

C. Pecharromán, T. Gonzalez-Carreno, J.E. Iglesias, The infrared dielectric properties of maghemite, γ-Fe2O3, from reflectance measurement on pressed powders. Phys. Chem. Miner. 22, 21–29 (1995)

A.M. Jubb, H.C. Allen, Vibrational spectroscopic characterization of hematite, maghemite, and magnetite thin films produced by vapor deposition. ACS Appl. Mater. Interfaces 2, 2804–2812 (2010)

P. Miles, W. Westphal, A. Von Hippel, Dielectric spectroscopy of ferromagnetic semiconductors. Rev. Mod. Phys. 29, 279 (1957)

N. Rezlescu, E. Rezlescu, Dielectric properties of copper containing ferrites. Phys. Status Solidi a 23, 575–582 (1974)

D. Ravinder, K. Latha, Electrical conductivity of Mn–Zn ferrites. J. Appl. Phys. 75, 6118–6120 (1994)

S. Mehraj, M.S. Ansari, Structural, electrical and magnetic properties of (Fe, Co) co-doped SnO2 diluted magnetic semiconductor nanostructures. Physica E 65, 84–92 (2015)

Y. Yuan, J. Yang, W. Wang, Z. Ye, J. Lu, Structural, dielectric and ferromagnetic behavior of (Zn, Co) co-doped SnO2 nanoparticles. Ceram. Int. 42, 17128–17136 (2016)

M. Pollak, Some aspects of non-steady state conduction in bands and hopping processes. In: Proceedings of the International Conference on Physics of Semiconductors (Exeter, 1962), p. 86

A.A. El Ata, M. El Nimr, S. Attia, D. El Kony, A. Al-Hammadi, Studies of AC electrical conductivity and initial magnetic permeability of rare-earth-substituted Li–Co ferrites. J. Magn. Magn. Mater. 297, 33–43 (2006)

Acknowledgements

This work is done by the support Higher Education Commission of Pakistan (HEC) under START-UP RESEARCH GRANT PROGRAM abbreviated as SRGP with Grant Nos 21-1732/SRGP/R&D/HEC/2017 and 21-1553/SRGP/R&D/HEC/2017, the Fundamental Research Funds for the HEC Pakistan. Higher Education Research Endowment Fund by Khyberpukhtunkhwa (KP) Government Grant No. PMU1-22/HEREF/2014–2015/Vol/IV-.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hussain, M., Khan, R., Zulfiqar et al. Dielectric and magnetic properties of cobalt doped γ-Fe2O3 nanoparticles. J Mater Sci: Mater Electron 30, 13698–13707 (2019). https://doi.org/10.1007/s10854-019-01747-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01747-6