Abstract

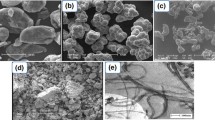

A novel technology was proposed to fabricate non-stoichiometric titanium dioxide (TiO2−x) compacts in one-step thermal process by in-situ reduction of rutile TiO2 with carbon powder via spark plasma sintering (SPS). The rutile TiO2 powder was reduced with three different carbon powders for comparison, and the effect of the sintering conditions on the fabricated compacts was investigated. It is found that the in-situ reduction of rutile TiO2 with charcoal powder was easily achieved at a low pressure and high temperature (above 1473 K). Besides, the design of dynamic sintering pressure during SPS was proposed, and the results suggest that the dynamic sintering pressure contributes to the reduction of TiO2 and the fabrication of the compacts with high-density. In addition, density methods, X-ray diffraction, scanning electronic microscopy and laser micro-Raman spectrometer were performed to analyze the sintering sates, microstructures, crystal structures and phase distributions. The results show that a stable sintering environment without an increase in the pressure caused by reaction gas is a crucial role for the reduction of TiO2 and the TiO2−x fabrication, even the formation of Magnéli phases TinO2n−1. Finer charcoal powder is more conducive to fabricating the compact with a single Magnéli phase Ti6O11. It is expected to achieve a new breakthrough in fabrication method of the non-stoichiometric TiO2 by a safe and economically viable method.

Similar content being viewed by others

References

F.J. Disalvo, Science 285, 703–705 (1999)

G.J. Snyder, E.S. Toberer, Nat. Mater. 7, 105–114 (2008)

G.P. Meisner, D.T. Morelli, S. Hu, J. Yang, C. Uher, Phys. Rev. Lett. 80, 3551–3554 (1998)

C. Ou, A.L. Sangle, A. Datta, Q. Jing, T. Busolo, T. Chalklen, V. Narayan, S. Kar-Narayan, A.C.S. Appl, Mater. Inter. 10, 19580–19587 (2018)

T. Favet, D. Ihiawakrim, V. Keller, T. Cottineau, Mat. Sci. Semicond. Process. 73, 22–29 (2018)

T. Zhu, Y. Liu, C. Fu, J.P. Heremans, J.G. Snyder, X. Zhao, Adv. Mater. 29, 1605884 (2017)

H. Liu, H. Ma, C. Wang, F. Wang, B. Liu, J. Chen, G. Ji, Y. Zhang, X. Jia, Ceram. Int. 44, 19859–19865 (2018)

J. Schneider, M. Matsuoka, M. Takeuchi, J. Zhang, Y. Horiuchi, M. Anpo, D.W. Bahnemann, Chem. Rev. 114, 9919–9986 (2014)

L. Yang, Z. Chen, M.S. Dargusch, J. Zou, Adv. Energy Mater. 8, 1701797 (2018)

A.E. Shalan, M. Mohammed, N. Govindan, RSC Adv. 11(8), 4417–4424 (2021)

H.R. An, S.Y. Park, H. Kim, C.Y. Lee, S. Choi, S.C. Lee, S. Seo, E.C. Park, Y.K. Oh, C.G. Song, J. Won, Y.J. Kim, J. Lee, H.U. Lee, Y.C. Lee, Sci. Rep. 6, 29683 (2016)

N. Okinaka, T. Akiyama, Jpn. J. Appl. Phys. 45, 7009–7010 (2006)

Q. He, Q. Hao, G. Chen, B. Poudel, X. Wang, D. Wang, Z. Ren, Appl. Phys. Lett. 91, 052505 (2007)

C. Liu, L. Miao, J. Zhou, R. Huang, C. Fisher, S. Tanemura, J. Phys. Chem. C 117, 11487–11497 (2013)

K. Fuda, T. Shoji, S. Kikuchi, Y. Kunihiro, S. Sugiyama, J. Electron. Mater. 42, 2209–2213 (2013)

W. Fang, M. Xing, J. Zhang, J. Photochem. Photobiol. C 32, 21–39 (2017)

I. Tsuyumoto, T. Hosono, M. Murata, J. Am. Ceram. Soc. 89(7), 2301–2303 (2006)

C. Tang, D. Zhou, Q. Zhang, Mater. Lett. 79, 42–44 (2012)

M. Mikami, K. Ozaki, J. Phys. Conf. Ser. 379, 012006 (2012)

S. Eslava, M. Mcpartlin, R.I. Thomson, J.M. Rawson, D.S. Wright, Inorg. Chem. 49, 11532–11540 (2010)

Y. Lu, Y. Matsuda, K. Sagara, L. Hao, T. Otomitsu, H. Yoshida, Adv. Mater. Res. 415, 1291–1296 (2012)

L. Hao, Y. Kikuchi, H. Yoshida, Y. Jin, Y. Lu, J. Alloy. Compd. 722, 846–851 (2017)

S. Conze, I. Veremchuk, M. Reibold, B. Matthey, A. Michaelis, Y. Grin, I. Kinski, J. Solid State Chem. 229, 235–242 (2015)

A.A. Gusev, E.G. Avvakumov, A.Z. Medvedev, A.I. Masliy, Sci. Sinter. 39, 51–57 (2007)

Y. Mikami, Development of the titanium oxynitride thermoelectric material, Report on achievements of scientific research grant. https://kaken.nii.ac.jp/file/KAKENHI-PROJECT-21760571/21760571seika.pdf. Accessed 19 March 2021

S. Guan, L. Hao, H. Yoshida, Y. Lu, X. Zhao, Mater. Express 7, 509–515 (2017)

L. Hao, S. Guan, Y. Lu, W. Qiu, Y. He, J. Liu, Surf. Coat. Tech. 291, 325–333 (2016)

J.V. Badding, Annu. Rev. Mater. Sci. 28, 631–665 (1998)

X.H. Wang, J.G. Li, H. Kamiyama, M. Katada, N. Ohashi, Y. Moriyoshi, T. Ishigaki, J. Am. Chem. Soc. 127, 10982–10990 (2005)

H. Yanagita, Particle Engineering System (Applied Technologies Inc., Osaka, 2002), pp. 89–90

M. Ali, P. Basu, J. Alloy. Compd. 500, 220–223 (2010)

Acknowledgements

This work is supported by the Scientific Research Foundation of the Japan Society for the Promotion of Science (JSPS, No. JP19K05053) and the China Scholarship Council.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Li, Z., Ohira, S. et al. Study on the fabricated non-stoichiometric titanium dioxide by in-situ reduction with carbon powder via spark plasma sintering. J Mater Sci: Mater Electron 32, 24698–24709 (2021). https://doi.org/10.1007/s10854-021-06861-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06861-y