Abstract

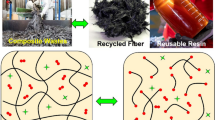

The present research aims to propose a comparative life cycle assessment (LCA) between the coffee capsules recycling process and the process of obtaining composites with coffee capsule outer packaging reinforced with 5 and 10% m/m of sugarcane bagasse fibers to evaluate the environmental impacts of each approach. The impact categories taken into consideration were: global warming, stratospheric ozone depletion, ozone formation, acidification and eutrophication, terrestrial, freshwater, and marine ecotoxicity, human carcinogenic toxicity, and human non-carcinogenic toxicity. The LCA of these materials show that obtaining composites process have favorable results in terms of environmental impacts compared to the recycling process of a coffee capsule in all impact categories. The values of acidification and eutrophication for the obtaining composites process were due to fertilizers’ use to cultivate sugarcane bagasse used to obtain the composite. The contribution analysis showed that the increase of fiber content decreases the amount of coffee capsule outer packaging necessary to acquire the composite and, consequently, reduces the environmental impacts caused by the process. GHG emissions indicated that the recycling process of coffee capsule residues has a higher CO2 eq emission. It was possible to observe that all analyses showed that the environmental performance of the process of obtaining composites of coffee capsule residues reinforced with sugarcane bagasse leads to a more sustainable approach when compared with the process of recycling coffee capsules, which is a sustainable alternative for recycling polymeric materials.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code Availability

The code used by author during the current study is available in the software SimaPro 9.1.1.

References

Gandia RM, Ferreira CA, Guimarães ER, Sugano JY, Rezende DC (2018) The coffee capsules consumption practice. RPCA. https://doi.org/10.12712/rpca.v12i2.1195

Brasil (2019) Ministério do Meio Ambiente. Política Nacional de Resíduos Sólidos Brasília: Ministério do Meio Ambiente. www.mma.gov.br/pol%C3%ADtica-de-res%C3%ADduos-s%C3%B3lidos. Accessed 20 June 2021

Diário do Comércio (2017) Nespresso investe na reciclagem de cápsulas. In: Revista Cafeicultura, Rio Paranaíba. http://revistacafeicultura.com.br/?mat=65407. Accessed 20 June 2021

Ecycle (2014) Sua pegada mais leve. https://www.ecycle.com.br/2243-capsulas-dolce-gusto-espresso-nespresso-de-cafe. Accessed 20 June 2021

Ragaert K, Delva L, Van Geem K (2017) Mechanical and chemical recycling of solid plastic waste. J Waste Manag. https://doi.org/10.1016/j.wasman.2017.07.044

Terracycle (2018) Reciclo: programa nacional de reciclagem de cápsulas de café. https://www.terracycle.com.br/pt-BR/brigades/reciclo-capsulas-de-cafe. Accessed 20 June 2021

Mothé CG, Monteiro DFJ, Mothé MG (2016) Dynamic mechanical and thermal behavior analysis of composites based on polypropylene recycled with vegetal leaves. Mater Sci Appl. https://doi.org/10.4236/msa.2016.77031

Karim R, Rahman F, Hasan M, Islam S, Hassan A (2013) Effect of fiber loading and alkali treatment on physical and mechanical properties of bagasse fiber reinforced polypropylene composites. J Polym Mater 30(4):423–433

Lila MK, Singhal A, Banwait SS, Singh I (2018) A recyclability study of bagasse fiber reinforced polypropylene composites. Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2018.05.001

Rosa CHSS, Mothé MG, Marques MFV, Mothé CG, Monteiro SN (2020) Steam-exploded fibers of almond tree leaves as reinforcement of novel recycled polypropylene composites. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2020.08.069

Joshi SV, Drzal LT, Mohanty AK, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos Part A Appl Sci Manuf. https://doi.org/10.1016/j.compositesa.2003.09.016

Dornburg V, Lewandowski I, Patel M (2004) Comparing the land requirements,energy savings, and greenhouse gas emissions reduction of biobased polymers and bioenergy. An analysis and system extension of life cycle assessment studies. J Ind Ecol. https://doi.org/10.1162/108819803323059424

Mohanty AK, Misra M, Drzal LT (2002) Sustainable bio-composites from renewable resources: opportunities and challenges in the green materials world. J Polym Environ. https://doi.org/10.1023/A:1021013921916

CONAB (2019) Companhia Nacional de Abastecimento. Observatório agrícola: acompanhamento da safra brasileira de cana-de-açúcar. https://www.conab.gov.br/info-agro/safras/cana/boletim-da-safra-de-cana-de-acucar/. Accessed 20 June 2021

Cardoso AA, Machado CMD, Pereira EA (2008) Biocombustível, o Mito do Combustível Limpo. Química Nova 28:9–14

Luz SM, Caldeira-Pires A, Ferrao PMC (2010) Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: Ecodesign and LCA as strategy for automotive components. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2010.03.009

Boland CS, De Kleine R, Keoleian GA, Lee EC, Kim HC, Wallington TJ (2015) Life cycle impacts of natural fiber composites for automotive applications: effects of renewable energy content and lightweighting. J Ind Ecol. https://doi.org/10.1111/jiec.12286

Riedel U, Nickel J (2003) Biocomposites: state-of-the-art and future perspectives. In: 7th International Conference on Wood Plastic Composites. Madison

Weiss M, Haufe J, Carus M, Brandão M, Bringezu S, Hermann B, Patel MK (2012) A review of the environmental impacts of biobased materials. J Ind Ecol. https://doi.org/10.1111/j.1530-9290.2012.00468.x

La Rosa AD, Recca G, Summerscales J, Latteri A, Cozzo G, Cicala G (2014) Bio-based versus traditional polymer composites. A life cycle assessment perspective. J Clean Prod. https://doi.org/10.1016/j.jclepro.2014.03.017

Saraiva AB, Pacheco EBAV, Gomes GM, Visconte LLY, Bernardo CA, Simões CL, Soares AG (2016) Comparative lifecycle assessment of mango packaging made from a polyethylene/natural fiber-composite and from cardboard material. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.08.135

Broeren MLM, Dellaert SNC, Cok B, Patel MK, Worrell E, Shen L (2017) Life cycle assessment of sisal fibre is exploring how local practices can influence environmental performance. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.02.073

Ramesh M (2019) Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: a review on preparation, properties and prospects. Prog Mater Sci. https://doi.org/10.1016/j.pmatsci.2018.12.004

Xu X, Jayaraman K, Morin C, Pecqueux N (2008) Life cycle assessment of wood-fiber reinforced polypropylene composites. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2007.06.087

Vidal R, Martínez P, Garraín D (2009) Life cycle assessment of composite materials made of recycled thermoplastics combined with rice husks and cotton linters. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-008-0043-7

Dissanayake NPJ, Summerscales J, Grove SM, Singh MM (2009) Energy use in the production of flax fiber for the reinforcement of composites. J Nat Fibers. https://doi.org/10.1080/15440470903345784

Dissanayake NPJ, Summerscales J, Grove SM, Singh MM (2009) Life cycle impact assessment of flax fibre for the reinforcement of composites. J Biobased Mater Bioenergy. https://doi.org/10.1166/jbmb.2009.1029

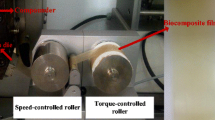

Soares APS, Freitas JS, Mothé MG, Mothé CG (2020) Thermal evaluation of composites from coffee capsules residue with sugarcane bagasse by TG/DTA and DMA. J Therm Anal. https://doi.org/10.1007/s10973-020-10012-6

Marie I, Quiasraei H (2012) Closed-loop recycling of recycled concrete aggregates. J Clean Prod. https://doi.org/10.1016/j.jclepro.2012.07.020

Maga D, Thonemann N, Markus HM, Sebastião D, Lopes TF, Fonseca C, Gírio F (2019) Comparative life cycle assessment of first- and second-generation ethanol from sugarcane in Brazil. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-018-1505-1

ISO (2006) ISO 14044: Environmental management—life cycle assessment—requirements and guidelines. The International Organization for Standardization (ISO), Geneva

Carpio LGT, Souza FS (2017) Optimal allocation of sugarcane bagasse for producing bioelectricity and second-generation ethanol in Brazil: scenarios of cost reductions. Renew Energy. https://doi.org/10.1016/j.renene.2017.05.015

Bomfim ASC, Voorwald HJC, Cioffi MOH, Benini KCCC (2018) Thermal properties study of recycled espresso coffee capsules for biocomposite application. In: 4th Brazilian conference on composite materials, pp 801–806

Hesser F (2015) Environmental advantage by choice: ex-ante LCA for a new Kraft pulp fibre reinforced polypropylene composite in comparison to reference materials. Compos Part B Eng. https://doi.org/10.1016/j.compositesb.2015.04.038

Câmara VB, Gallotti ME, Carvalho SMP, Peralta PP, Pereira EA, Pinheiro VS (2017) Cápsula de café: uma análise com base em teoria da inovação buscando agregar valor à balança comercial brasileira. Cad Prospec. https://doi.org/10.9771/cp.v10i2.17925

Spinacé MAS, Paoli MA (2005) The technology of polymer recycling. Quim Nova. https://doi.org/10.1590/S0100-40422005000100014

ILCD (2011) ILCD Handbook: recommendations for life cycle impact assessment in the European context. European Commission, Joint Research Centre, Institute for Environment and Sustainability

Mendes NC, Bueno C, Ometto AR (2013) Avaliação de Impacto do Ciclo de Vida: revisão dos principais métodos. Prod. https://doi.org/10.1590/0103-6513.153213

Brasil (2020) Ministry of Agriculture. Plano Setorial de Mitigação e de Adaptação às Mudanças Climáticas para a Consolidação de uma Economia de Baixa Emissão de Carbono na Agricultura (Sector Plan for Mitigation and Adaptation to Climate Change for the Consolidation of Economy Low Carbon in Agriculture). www.agricultura.gov.br/desenvolvimento-sustentavel/plano-abc. Accessed 20 Jan 2021

GHG Protocol (2021) https://ghgprotocol.org/about-us. Accessed 20 June 2021

Muller-Samann KM, Reinhardt GA, Vetter R, Gartner SO (2002) Biomass resources in Baden-Wurttemberg: Identifying environmentally favorable bio-based products. Report FZKA-BWPLUS, BWA 20002. Muhlheim, Germany: Institut fur umweltgerechte Landbewirtschaftung (IfuL) and Heidelberg. Institut fur Energie- und Umweltforschung Heidelberg GmbH (IFEU)

Harding KG, Dennis JS, von Blottnitz H, Harrison STL (2007) Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol. https://doi.org/10.1016/j.jbiotec.2007.02.012

Shen L, Patel MK (2010) Life cycle assessment of man-made cellulose fibres. Lenzinger Ber 88:1–59

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. The authors express gratitude to Thermal Analysis RJ Professor Ivo Giolito Laboratory and Leni Leite Rheology Laboratory, School of Chemistry/UFRJ- Brazil.

Author information

Authors and Affiliations

Contributions

APSS: conceptualization, methodology, formal analysis, investigation, writing—original draft, visualization. MGM: resources, writing—review & editing, supervision, project administration. CGM: resources, writing—review & editing, supervision, project administration.

Corresponding author

Ethics declarations

Competing interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soares, A.P.S., Mothé, C.G. & Mothé, M.G. Comparative Life Cycle Assessment of Coffee Capsule Recycling Process and Its Composites Reinforced with Natural Fibers. J Polym Environ 30, 1380–1390 (2022). https://doi.org/10.1007/s10924-021-02282-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02282-4