Abstract

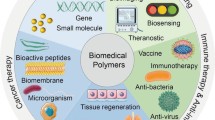

CO2 mitigation by cycloaddition to bis-epoxides to obtain bis-cyclocarbonates (CC) paved one way to a new class of polyurethanes (PUs), the non-isocyanate polyurethanes (NIPUs). By using molecules functionalized with alkoxysilyl groups as end chain it is possible to obtain hybrid NIPUs, also called urethanesils, by sol–gel chemistry. Using bis-cyclocarbonate polydimethylsiloxane (CCPDMS) with proper diamines and end-chain amino silanes followed by sol–gel processing leads to versatile hybrid non-isocyanate polydimethylsiloxane urethanes (PDMS-urethanesil). This review reports—besides our recent studies about PDMS-urethanesil materials—the sol–gel chemistry applied to synthesize urethanesil and its applications. While the antimicrobial, photochromic, and anticorrosion properties of urethanesil loaded with phosphotungstic acid as well as the luminescent effect of material loaded with Eu3+ have already been reported, antimicrobial features of urethanesil loaded with phosphoric acid are our newest findings which we herein report for the first time. The impact of the inorganic acid used on the sol–gel process is highlighted together with the importance of antibiofouling properties. Although the antibiofouling mechanism is still under investigation, the broad spectrum of action of phosphoric acid-loaded urethanesil is worth mentioning, since it has been tested to be efficient against some pathogenic bacteria including a drug resistant Staphylococcus aureus strain as well as pathogenic fungi and yeast. Due to the simple, straightforward, and highly reproducible synthesis as well as the opportunity to obtain versatile materials with tuneable mechanical and physical properties, this new class of hybrid materials promises to be applicable in different industrial fields.

Highlights

-

Combining CO2 use and sol–gel processing yields versatile PDMS-urethanesils with tunable properties.

-

Key approach: combine non-isocyanate PU with silica and PDMS through aminolysis of cyclocarbonate.

-

Morphology control using inorganic acid as catalyst for sol–gel process.

-

Inorganic loading defines the application, e.g., as anticorrosion coating or as white-light emitter.

-

Novel finding with new applications, e.g., antimicrobial activity against pathogenic microorganisms.

Similar content being viewed by others

References

Sharmin, Zafar, F (2012) Polyurethane: an introduction. In: Sharmin, Zafar, F (eds) Polyurethane. Intech Open, London, pp 3–16

Cornille A, Auvergne R, Figovsky O et al. (2017) A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur Polym J 87:535–552. https://doi.org/10.1016/j.eurpolymj.2016.11.027

Akindoyo JO, Beg MDH, Ghazali S et al. (2016) Polyurethane types, synthesis and applications—a review. RSC Adv 6:114453–114482. https://doi.org/10.1039/C6RA14525F

Biesmans G (2010) The global polyurethane market. In: Randall D, Lee S (eds) The Huntsmann polyurethanes book. John Wiley & Sons, Everberg, pp 9–22

Sanchez C, Rozes L, Ribot F et al. (2010) “Chimie douce”: a land of opportunities for the designed construction of functional inorganic and hybrid organic-inorganic nanomaterials. Comptes Rendus Chim 13:3–39. https://doi.org/10.1016/j.crci.2009.06.001

Bello D, Herrick CA, Smith TJ et al. (2007) Skin exposure to isocyanates: reasons for concern. Environ Health Perspect 115:328–335. https://doi.org/10.1289/ehp.9557

Kathalewar MS, Joshi PB, Sabnis AS, Malshe VC (2013) Non-isocyanate polyurethanes: from chemistry to applications. RSC Adv 3:4110. https://doi.org/10.1039/c2ra21938g

Blattmann H, Fleischer M, Bähr M, Mülhaupt R (2014) Isocyanate- and phosgene-free routes to polyfunctional cyclic carbonates and green polyurethanes by fixation of carbon dioxide. Macromol Rapid Commun 35:1238–1254. https://doi.org/10.1002/marc.201400209

Maisonneuve L, Lamarzelle O, Rix E et al. (2015) Isocyanate-free routes to polyurethanes and poly(hydroxy urethane)s. Chem Rev 115:12407–12439. https://doi.org/10.1021/acs.chemrev.5b00355

Bossion A, Jones GO, Taton D et al. (2017) Non-Isocyanate polyurethane soft nanoparticles obtained by surfactant-assisted interfacial polymerization. Langmuir 33:1959–1968. https://doi.org/10.1021/acs.langmuir.6b04242

Rockström J, Schellnhuber HJ, Hoskins B et al. (2016) The world’s biggest gamble. Earth’s Futur 4:465–470. https://doi.org/10.1002/2016EF000392

Aresta M (2010) Carbon dioxide as chemical feedstock. Wiley, Chichester, UK

Duraccio V, Gnoni MG, Elia V (2015) Carbon capture and reuse in an industrial district: a technical and economic feasibility study. J CO2 Util 10:23–29. https://doi.org/10.1016/j.jcou.2015.02.004

Beniah G, Uno BE, Lan T et al. (2017) Tuning nanophase separation behavior in segmented polyhydroxyurethane via judicious choice of soft segment. Polymer 110:218–227. https://doi.org/10.1016/j.polymer.2017.01.017

Beniah G, Heath WH, Torkelson JM (2017) Functionalization of hydroxyl groups in segmented polyhydroxyurethane eliminates nanophase separation. J Polym Sci Part A Polym Chem 55:3347–3351. https://doi.org/10.1002/pola.28722

Pan WC, Lin C-H, Dai SA (2014) High-performance segmented polyurea by transesterification of diphenyl carbonates with aliphatic diamines. J Polym Sci Part A Polym Chem 52:2781–2790. https://doi.org/10.1002/pola.27302

Figovsky O, Leykin A, Shapovalov L (2016) Non-isocyanate polyurethanes—yesterday, today and tomorrow. Alter Energy Ecol 3–4:95–108. https://doi.org/10.15518/isjaee.2016.03-04.009

Figovsky O, Beilin D (2013) Advanced polymer concretes and compounds. CRC Press, Boca Raton, USA

Figovsky OL, Shapovalov L, Leykin A et al. (2013) Progress in elaboration of nonisocyanate polyurethanes based on cyclic carbonates. Int Lett Chem Phys Astron 3:52–66. https://doi.org/10.18052/www.scipress.com/ILCPA.3.52

Pilch-Pitera B (2014) Polyurethane powder coatings containing polysiloxane. Prog Org Coat 77:1653–1662. https://doi.org/10.1016/j.porgcoat.2014.05.021

Henderson CMB (1987) Structural chemistry of silicates; structure, bonding and classification. Earth-Sci Rev 24:154–155. https://doi.org/10.1016/0012-8252(87)90019-5

Willerth S (2017) Engineering neural tissue from stem cells. Academic Press, Cambridge, Massachusetts

Liu C (2015) Development of anti-fouling coating using in marine environment. Int J Environ Monit Anal 3:373. https://doi.org/10.11648/j.ijema.20150305.30

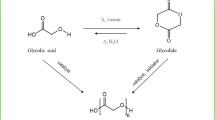

Aguiar KR, Santos VG, Eberlin MN et al. (2014) Efficient green synthesis of bis(cyclic carbonate) poly(dimethylsiloxane) derivative using CO2 addition: a novel precursor for synthesis of urethanes. RSC Adv 24334–24343. https://doi.org/10.1039/c4ra03846k

Rossi de Aguiar KMF, Alves VS, Noeske P-LM et al (2019) Hybrid films based on nonisocyanate polyurethanes with antimicrobial activity. In: Materials for biomedical engineering. Elsevier, Amsterdam, pp 77–116

Simões MB, Ullah S, Hazra C et al. (2018) Eco-friendly polydimethylsiloxane-based self-supporting film containing europium-polyoxometalate: a flexible luminescent material for white light generation. J Lumin 201:384–389. https://doi.org/10.1016/j.jlumin.2018.04.041

Rossi de Aguiar KMF, Nascimento MV, Faccioni JL et al. (2019) Urethanes PDMS-based: functional hybrid coatings for metallic dental implants. Appl Surf Sci 484:1128–1140. https://doi.org/10.1016/j.apsusc.2019.04.058

Rossi de Aguiar KMF, Specht U, Maass JF et al. (2016) Surface modification by physical treatments on biomedical grade metals to improve adhesion for bonding hybrid non-isocyanate urethanes. RSC Adv 6:47203–47211. https://doi.org/10.1039/C6RA05397A

Rossi De Aguiar KMF, Ferreira-Neto EP, Blunk S et al. (2016) Hybrid urethanesil coatings for inorganic surfaces produced by isocyanate-free and sol-gel routes: Synthesis and characterization. RSC Adv 6:19160–19172. https://doi.org/10.1039/c5ra24331a

de Aguiar KR, Rischka K, Gätjen L et al. (2018) Biomimetic PDMS-hydroxyurethane terminated with catecholic moieties for chemical grafting on transition metal oxide-based surfaces. Appl Surf Sci 427:166–175. https://doi.org/10.1016/j.apsusc.2017.08.142

Lima EF de S, Imasato H, Cavalheiro ETG et al. (2019) Effect of hydroxyapatite nanoparticles silanization on the preparation of nanocomposites of Hydroxyurethane polydimethylsiloxane with hydroxyapatite. In: Encontro da Sociedade Brasileira de Pesquisa em Materiais—SBPMat. Sociedade Brasileira de Pesquisa em Materiais—SBPMat. Camboriú, SC, Brazil

Bayer O (1947) Das Di-Isocyanat-Polyadditionsverfahren (Polyurethane). Angew Chemie. https://doi.org/10.1002/ange.19470590901

Boiteux G, Cuvé L, Pascault JP (1994) Synthesis and properties of polyurethanes based on polyolefin: 3. monitoring of phase separation by dielectric relaxation spectroscopy of segmented semicrystalline polyurethane prepared in bulk by the use of emulsifiers. Polymer. https://doi.org/10.1016/0032-3861(94)90068-X

Urbano J, Manzarbetia F, Caramelo C (2008) Cholesterol embolism evaluated by polarized light microscopy after primary renal artery stent placement with filter protection. J Vasc Inter Radio 19:189–194. https://doi.org/10.1016/j.jvir.2007.10.006

St. John KR (2014) The use of polyurethane materials in the surgery of the spine: a review. Spine J 14:3038–3047. https://doi.org/10.1016/j.spinee.2014.08.012

Usman A, Zia KM, Zuber M et al. (2016) Chitin and chitosan based polyurethanes: a review of recent advances and prospective biomedical applications. Int J Biol Macromol 86:630–645. https://doi.org/10.1016/j.ijbiomac.2016.02.004

Korthagen NM, Brommer H, Hermsen G et al. (2019) A short-term evaluation of a thermoplastic polyurethane implant for osteochondral defect repair in an equine model. Vet J 251:105340. https://doi.org/10.1016/j.tvjl.2019.105340

de Vita R, Buccheri EM, Villanucci A, Pozzi M (2019) Breast reconstruction actualized in nipple-sparing mastectomy and direct-to-implant, prepectoral polyurethane positioning: early experience and preliminary results. Clin Breast Cancer 19:e358–e363. https://doi.org/10.1016/j.clbc.2018.12.015

Alves P, Ferreira P, Gil MH (2012) Biomedical polyurethanes-based materials. In: Polyurethane: properties, structure and applications. Nova Publishers, New York, NY, pp 1–25

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2019) Bio-based routes to synthesize cyclic carbonates and polyamines precursors of non-isocyanate polyurethanes: a review. Eur Polym J 118:668–684. https://doi.org/10.1016/j.eurpolymj.2019.06.032

Tersac G (2007) Chemistry and technology of polyols for polyurethanes. Milhail Ionescu. Rapra Technology, Shrewsbury, UK. Polym Int 56:820–820. https://doi.org/10.1002/pi.2159

Zia KM, Anjum S, Zuber M et al. (2014) Synthesis and molecular characterization of chitosan based polyurethane elastomers using aromatic diisocyanate. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2014.01.073

Engels H-W, Pirkl H-G, Albers R et al. (2013) Polyurethanes: versatile materials and sustainable problem solvers for today’s challenges. Angew Chem Int Ed 52:9422–9441. https://doi.org/10.1002/anie.201302766

Cypryk M, Apeloig Y (2002) Mechanism of the acid-catalyzed Si-O bond cleavage in siloxanes and siloxanols. A theoretical study. Organometallics 21:2165–2175. https://doi.org/10.1021/om011055s

Fugel M, Hesse MF, Pal R et al. (2018) Covalency and ionicity do not oppose each other-relationship between Si−O bond character and basicity of siloxanes. Chem Eur J 24:15275–15286. https://doi.org/10.1002/chem.201802197

Weinhold F, West R (2011) The nature of the silicon–oxygen bond. Organometallics 30:5815–5824. https://doi.org/10.1021/om200675d

Gillespie RJ, Johnson SA (1997) Study of bond angles and bond lengths in disiloxane and related molecules in terms of the topology of the electron density and its Laplacian. Inorg Chem 36:3031–3039. https://doi.org/10.1021/ic961381d

Kickelbick G (2006) Hybrid materials. Wiley, Chichester, UK

Whan Cho J, Il Sul K (2001) Characterization and properties of hybrid composites prepared from poly(vinylidene fluoride–tetrafluoroethylene) and SiO2. Polymer 42:727–736. https://doi.org/10.1016/S0032-3861(00)00371-2

Kim K-M, Adachi K, Chujo Y (2002) Polymer hybrids of functionalized silsesquioxanes and organic polymers utilizing the sol–gel reaction of tetramethoxysilane. Polymer 43:1171–1175. https://doi.org/10.1016/S0032-3861(01)00732-7

Wen J, Wilkes GL (1996) Organic/inorganic hybrid network materials by the sol−gel approach. Chem Mater 8:1667–1681. https://doi.org/10.1021/cm9601143

Pavličević J, Špírková M, Jovičić M et al. (2019) Structure—functional property relationship of aliphatic polyurethane-silica hybrid films. Prog Org Coat 126:62–74. https://doi.org/10.1016/j.porgcoat.2018.10.011

He Z, Gao T, Duan D, Soucek MD (2019) Effect of mixed sol-gel precursors on inorganic-organic polyurethane hybrid thermosets: DOE study. Prog Org Coat. https://doi.org/10.1016/j.porgcoat.2019.04.023

Alasti Bonab S, Moghaddas J, Rezaei M (2019) In-situ synthesis of silica aerogel/polyurethane inorganic-organic hybrid nanocomposite foams: characterization, cell microstructure and mechanical properties. Polymer 172:27–40. https://doi.org/10.1016/j.polymer.2019.03.050

Son S-J, Kim K-B, Lee Y-H et al. (2011) Effect of acrylic monomer content on the properties of waterborne poly(urethane-urea)/acrylic hybrid materials J Appl Polym Sci 124. https://doi.org/10.1002/app.35662

Athawale VD, Kulkarni MA (2009) Preparation and properties of urethane/acrylate composite by emulsion polymerization technique. Prog Org Coat 65:392–400

Ping T, Zhou Y, He Y et al. (2016) Preparation and characterization of yellowing resistance and low volume shrinkage of fluorinated polysiloxane urethane acrylate. Prog Org Coat 97:74–81. https://doi.org/10.1016/j.porgcoat.2016.03.023

Cakić SM, Valcic MD, Ristić IS et al. (2019) Waterborne polyurethane-silica nanocomposite adhesives based on castor oil-recycled polyols: effects of (3-aminopropyl)triethoxysilane (APTES) content on properties. Int J Adhes Adhes 90:22–31. https://doi.org/10.1016/j.ijadhadh.2019.01.005

Kreye O, Mutlu H, Meier MAR (2013) Sustainable routes to polyurethane precursors. Green Chem 15:1431. https://doi.org/10.1039/c3gc40440d

Joshi M, Adak B, Butola BS (2018) Polyurethane nanocomposite based gas barrier films, membranes and coatings: a review on synthesis, characterization and potential applications. Prog Mater Sci 97:230–282. https://doi.org/10.1016/j.pmatsci.2018.05.001

Błażek K, Datta J (2019) Renewable natural resources as green alternative substrates to obtain bio-based non-isocyanate polyurethanes-review. Crit Rev Environ Sci Technol 49:173–211. https://doi.org/10.1080/10643389.2018.1537741

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2020) Synthesis of green hybrid materials using starch and non-isocyanate polyurethanes. Carbohydr Polym 229:115535. https://doi.org/10.1016/j.carbpol.2019.115535

Suryawanshi Y, Sanap P, Wani V (2019) Advances in the synthesis of non-isocyanate polyurethanes. Polym Bull 76:3233–3246. https://doi.org/10.1007/s00289-018-2531-7

Datta J, Włoch M (2016) Progress in non-isocyanate polyurethanes synthesized from cyclic carbonate intermediates and di- or polyamines in the context of structure–properties relationship and from an environmental point of view. Polym Bull 73:1459–1496. https://doi.org/10.1007/s00289-015-1546-6

Heilig ML (1994) United States patent office. ACM SIGGRAPH Comput Graph 28:131–134. https://doi.org/10.1145/178951.178972

Zabalov MV, Tiger RP, Berlin AA (2012) Mechanism of urethane formation from cyclocarbonates and amines: a quantum chemical study. Russ Chem Bull 61:518–527. https://doi.org/10.1007/s11172-012-0076-8

Zabalov MV, Levina MA, Krasheninnikov VG, Tiger RP (2014) Bifunctional catalysis by acetic acid in the urethane formation from cyclocarbonates and amines: quantum chemical and kinetic study. Russ Chem Bull 63:1740–1752. https://doi.org/10.1007/s11172-014-0662-z

Tomita H, Sanda F, Endo T (2001) Model reaction for the synthesis of polyhydroxyurethanes from cyclic carbonates with amines: substituent effect on the reactivity and selectivity of ring-opening direction in the reaction of five-membered cyclic carbonates with amine. J Polym Sci Part A Polym Chem 39:3678–3685. https://doi.org/10.1002/pola.10009

Günther F, Batista Simões M, Imasato H, Pereira Rodrigues-Filho U (2019) Experimental and theoretical assessment of the aminolysis of cyclo carbonate to form polyhydroxyurethanes. Mater Today Commun 21:100604. https://doi.org/10.1016/j.mtcomm.2019.100604

Lambeth RH, Rizvi A (2019) Mechanical and adhesive properties of hybrid epoxy-polyhydroxyurethane network polymers. Polymer 183:121881. https://doi.org/10.1016/j.polymer.2019.121881

Sukumaran Nair A, Cherian S, Balachandran N et al. (2019) Hybrid poly(hydroxy urethane)s: folded-sheet morphology and thermoreversible adhesion. ACS Omega 4:13042–13051. https://doi.org/10.1021/acsomega.9b00789

North M, Pasquale R, Young C (2010) Synthesis of cyclic carbonates from epoxides and CO2. Green Chem 12:1514. https://doi.org/10.1039/c0gc00065e

Martín C, Fiorani G, Kleij AW (2015) Recent advances in the catalytic preparation of cyclic organic carbonates. ACS Catal 5:1353–1370. https://doi.org/10.1021/cs5018997

Subramaniam A, Sethuraman S (2014) Biomedical applications of nondegradable polymers. In: Kumbar SG, Laurencin CT, Deng M (eds) Natural and Synthetic Biomedical Polymers. Elsevier Science, Amsterdam, pp. 301–308

Schindler WD, Hauser PJ (2004) Chemical finishing of textiles. Woodhead Publishing Limited, Sawston, Cambridge, UK

Ben Soltane H, Roizard D, Favre E (2013) Effect of pressure on the swelling and fluxes of dense PDMS membranes in nanofiltration: an experimental study. J Memb Sci 435:110–119. https://doi.org/10.1016/j.memsci.2013.01.053

Stefanis E, Panayiotou C (2008) Prediction of hansen solubility parameters with a new group-contribution method. Int J Thermophys 29:568–585. https://doi.org/10.1007/s10765-008-0415-z

Belmares M, Blanco M, Goddard WA et al. (2004) Hildebrand and hansen solubility parameters from molecular dynamics with applications to electronic nose polymer sensors. J Comput Chem 25:1814–1826. https://doi.org/10.1002/jcc.20098

Bahri S, Jonsson CM, Jonsson CL et al. (2011) Adsorption and surface complexation study of L-DOPA on rutile (α-TiO2) in NaCl solutions. Environ Sci Technol 45:3959–3966. https://doi.org/10.1021/es1042832

Grunwald I, Rischka K, Kast SM et al. (2009) Mimicking biopolymers on a molecular scale: nano(bio)technology based on engineered proteins. Philos Trans R Soc A Math Phys Eng Sci 367:1727–1747. https://doi.org/10.1098/rsta.2009.0012

Zdyb A, Krawczyk S (2016) Characterization of adsorption and electronic excited states of quercetin on titanium dioxide nanoparticles. Spectrochim Acta Part A Mol Biomol Spectrosc 157:197–203. https://doi.org/10.1016/j.saa.2016.01.006

Liu G, Wu G, Huo S et al. (2017) Synthesis and properties of non-isocyanate polyurethane coatings derived from cyclic carbonate-functionalized polysiloxanes. Prog Org Coat 112:169–175. https://doi.org/10.1016/j.porgcoat.2017.07.013

Lana SLB, Seddon AB (1998) X-ray diffraction studies of sol-gel derived ORMOSILs based on combinations of tetramethoxysilane and trimethoxysilane. J Sol-Gel Sci Technol 13:461–466. https://doi.org/10.1023/A:1008685614559

Moreno EM, Levy D (2000) Role of the comonomer GLYMO in ORMOSILs as reflected by nile red spectroscopy. Chem Mater 12:2334–2340. https://doi.org/10.1021/cm001048e

Brennan JD, Hartman JS, Ilnicki EI, Rakic M (1999) Fluorescence and NMR characterization and biomolecule entrapment studies of sol−gel-derived organic−inorganic composite materials formed by sonication of precursors. Chem Mater 11:1853–1864. https://doi.org/10.1021/cm9910097

Ferreira-Neto EP, Ullah S, Ysnaga OAE, Rodrigues-Filho UP (2014) Zn2+ doped ormosil–phosphotungstate hybrid films with enhanced photochromic response. J Sol-Gel Sci Technol 72:290–300. https://doi.org/10.1007/s10971-014-3404-7

Frenkel-Mullerad H, Ben-Knaz R, Avnir D (2014) Preserving the activity of enzymes under harsh oxidizing conditions: sol–gel entrapped alkaline phosphatase exposed to bromine. J Sol-Gel Sci Technol 69:453–456. https://doi.org/10.1007/s10971-013-3226-z

Cuéllar-Franca RM, Azapagic A (2015) Carbon capture, storage and utilisation technologies: a critical analysis and comparison of their life cycle environmental impacts. J CO2 Util 9:82–102. https://doi.org/10.1016/j.jcou.2014.12.001

Rubio F, Rubio J, Oteo JL (2000) Effect of TiO2 on the pore structure of SiO2-PDMS ormosils. J Sol-Gel Sci Technol. https://doi.org/10.1023/A:1008704701204

Almeida JC, Wacha A, Gomes PS et al. (2016) PDMS-SiO2-TiO2-CaO hybrid materials—cytocompatibility and nanoscale surface features. Mater Sci Eng C 64:74–86. https://doi.org/10.1016/j.msec.2016.03.071

Doro FG, Ramos AP, Schneider JF et al. (2014) Deposition of organic−inorganic hybrid coatings over 316L surgical stainless steel and evaluation on vascular cells. Can J Chem 92:987–995. https://doi.org/10.1139/cjc-2014-0034

Rodrigues-Filho UP, de Aguiar KMF, Rischka K (2017) Processo de obtenção de materiais derivados de polidimetilsiloxano (Pdms) materiais derivados de polidimetilsiloxano (Pdms) E Seus Usos. BR 102015024615-3 A2. The National Institute of Industrial Property (INPI)

Mackenzie JD, Bescher E (2003) Some factors governing the coating of organic polymers by sol-gel derived hybrid materials. J Sol-Gel Sci Technol 27:7–14. https://doi.org/10.1023/A:1022659323517

Wu Y, Guo P, Zhao Y et al. (2019) Hydrophobic, transparent waterborne polyurethane-polydimethylsiloxane composites prepared from aqueous sol-gel process and applied in corrosion protection. Prog Org Coat 127:231–238. https://doi.org/10.1016/j.porgcoat.2018.06.002

de Aguiar KMFR (2015) Síntese de hidroxiuretana-poli (dimetilsiloxano) com diferentes terminações de cadeia via fixação de CO2: síntese, caracterizações e potenciais aplicações. Universidade de São Paulo, São Paulo

Ferreira-Neto EP, de Carvalho FLS, Ullah S et al. (2013) Surface structure and reactivity study of phosphotungstic acid-nitrogenated ormosils. J Sol-Gel Sci Technol 66:363–371. https://doi.org/10.1007/s10971-013-3018-5

Souza AL, Marques LA, Eberlin MN et al. (2012) Self-assembled hybrid films of phosphotungstic acid and aminoalkoxysilanes on SiO2/Si surfaces. Thin Solid Films 520:3574–3580. https://doi.org/10.1016/j.tsf.2011.12.069

Leroy F, Miró P, Poblet JM et al. (2008) Keggin polyoxoanions in aqueous solution: ion pairing and its effect on dynamic properties by molecular dynamics simulations. J Phys Chem B 112:8591–8599. https://doi.org/10.1021/jp077098p

Marcus Y (2009) Effect of ions on the structure of water: structure making and breaking. Chem Rev 109:1346–1370. https://doi.org/10.1021/cr8003828

Ball P, Hallsworth JE (2015) Water structure and chaotropicity: their uses, abuses and biological implications. Phys Chem Chem Phys 17:8297–8305. https://doi.org/10.1039/C4CP04564E

Collins KD, Neilson GW, Enderby JE (2007) Ions in water: characterizing the forces that control chemical processes and biological structure. Biophys Chem 128:95–104. https://doi.org/10.1016/j.bpc.2007.03.009

Costa AO, Oliveira LB, Lins MPE et al. (2013) Sustainability analysis of biodiesel production: a review on different resources in Brazil. Renew Sustain Energy Rev 27:407–412. https://doi.org/10.1016/j.rser.2013.06.005

Thangaraj B, Solomon PR, Muniyandi B et al. (2019) Catalysis in biodiesel production—a review. Clean Energy 3:2–23. https://doi.org/10.1093/ce/zky020

Mousdale D (2008) Diversifying the biofuels portfolio. In: Biofuels. CRC Press, Boca Raton, pp 285–320

Danaei SM, Safavi A, Roeinpeikar SMMM et al. (2011) Ion release from orthodontic brackets in 3 mouthwashes: An in-vitro study. Am J Orthod Dentofac Orthop 139:730–734. https://doi.org/10.1016/j.ajodo.2011.03.004

De Morais LS, Guimarães GS, Elias CN (2007) Liberação de íons por biomateriais metálicos. Rev Dent Press Ortod e Ortop Facial 12:48–53. https://doi.org/10.1590/S1415-54192007000600006

Nuevo-Ordóñez Y, Montes-Bayón M, Blanco-González E et al. (2011) Titanium release in serum of patients with different bone fixation implants and its interaction with serum biomolecules at physiological levels. Anal Bioanal Chem 401:2747–2754. https://doi.org/10.1007/s00216-011-5232-8

Yang X, Vang C, Tallman D et al. (2001) Weathering degradation of a polyurethane coating. Polym Degrad Stab 74:341–351. https://doi.org/10.1016/S0141-3910(01)00166-5

Kowalczyk K, Łuczka K, Grzmil B, Spychaj T (2012) Anticorrosive polyurethane paints with nano- and microsized phosphates. Prog Org Coat 74:151–157. https://doi.org/10.1016/j.porgcoat.2011.12.003

Yang XF, Tallman DE, Bierwagen GP et al. (2002) Blistering and degradation of polyurethane coatings under different accelerated weathering tests. Polym Degrad Stab 77:103–109. https://doi.org/10.1016/S0141-3910(02)00085-X

Drago RS, Dias JA, Maier TO (1997) An acidity scale for brönsted acids including H3PW12O40. J Am Chem Soc 119:7702–7710. https://doi.org/10.1021/ja9639123

Dhivya S, Padma VV, Santhini E (2015) Wound dressings—a review. BioMedicine 5:22. https://doi.org/10.7603/s40681-015-0022-9

Fu S, Chu J, Chen X et al. (2015) Well-Dispersed H3PW12O40/H4SiW12O40 nanoparticles on mesoporous polymer for highly efficient acid-catalyzed reactions. Ind Eng Chem Res 54:11534–11542. https://doi.org/10.1021/acs.iecr.5b03385

Essayem N, Frety R, Coudurier G, Vedrine JC (1997) Ammonia adsorption-desorption over the strong solid acid catalyst H3PW12O4o and its Cs+ and NH4+ salts comparison with sulfated zirconia. J Chem Soc Faraday Trans 93:3243–3248. https://doi.org/10.1039/a701097d

Medilanski E, Kaufmann K, Wick LY et al. (2002) Influence of the surface topography of stainless steel on bacterial adhesion. Biofouling 18:193–203. https://doi.org/10.1080/08927010290011370

Piva RH, Rocha MC, Piva DH et al. (2018) Acidic dressing based on agarose/Cs2.5H0.5PW12O40 nanocomposite for infection control in wound care. ACS Appl Mater Interfaces 10:30963–30972. https://doi.org/10.1021/acsami.8b09066

Liu B, Wang YL, Bai W et al. (2017) Fluorescent linear CO2-derived poly(hydroxyurethane) for cool white LED. J Mater Chem C. https://doi.org/10.1039/c7tc01236e

Xu W, Liu B, Cai X et al. (2018) Fluorescent poly(hydroxyurethane): biocompatibility evaluation and selective detection of Fe(III). J Appl Polym Sci 135:46723. https://doi.org/10.1002/app.46723

Carlos LD, Sá Ferreira RA, De Zea Bermudez V, Ribeiro SJL (2001) Full-color phosphors from amine-functionalized crosslinked hybrids lacking metal activator ions. Adv Funct Mater 11:111–115. https://doi.org/10.1002/1616-3028(200104)11:2<111::AID-ADFM111>3.0.CO;2-V3.0.CO;2-V

Neves CS, Granadeiro CM, Cunha-Silva L et al. (2013) Europium polyoxometalates encapsulated in silica nanoparticles—characterization and photoluminescence studies Eur J Inorg Chem 2877–2886. https://doi.org/10.1002/ejic.201201482

Landau R (1998) The process of innovation in the chemical industry. In: Arora A, Landau R, Rosenberg N (eds) Chemicals and long-term economic growth. insights from the chemical industry. John Wiley & Sons Inc, New York, USA, pp 139–180

Acknowledgements

The authors would like to thank the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) for the grants 2011/06019-0, 2013/05279-3, 2011/08120-0, 2018/19785-1, and 2018/15670-5. Furthermore, the support of Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for the grants 302185/2017-8 is acknowledged, as well as the German Academic Exchange Service (DAAD) for grant 57210526. Further thanks go to the joint PROBRAL program between Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and DAAD for grant 8881.198673/2018-01 for fostering the Brazilian-German bilateral collaboration.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Günther, F., Lima, E.F.S., Rossi de Aguiar, K.M.F. et al. PDMS-urethanesil hybrid multifunctional materials: combining CO2 use and sol–gel processing. J Sol-Gel Sci Technol 95, 693–709 (2020). https://doi.org/10.1007/s10971-020-05376-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05376-y