Abstract

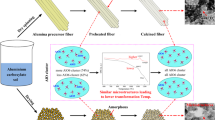

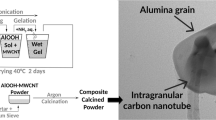

Controlling the density and the nanograin size is challenging but essential to prepare continuous alumina fibers with excellent performance. In this study, the continuous alumina fibers were prepared using the sol-gel method. The fibers calcined under different conditions were characterized to reveal the effect of calcining conditions on the fiber microstructure evolution. The results show that the phase transformation from amorphous Al2O3 to γ-Al2O3 and then to α-Al2O3 takes place during the calcining process. The fiber, prepared using a single-step calcining method, cannot obtain a fully dense and nanocrystal microstructure through optimizing the calcination conditions. Thus, a novel two-step calcining process was proposed, through which an almost fully dense α-Al2O3 fiber with an average grain size of ~150 nm was prepared and the tensile strength of fibers reaches 2.2 GPa. Based on the results, the effect mechanism of residual organics, phase transformation, densifying, and grain growth on the fiber microstructure evolution was discussed in depth.

Graphical abstract

Highlights

-

The full dense alumina fiber with nanograins were prepared using a novel two-step calcination.

-

The tensile strength of alumina fibers reaches up to 2.2 GPa.

-

The influencing mechanism of organics removal, phase transformation, grain growth, and densification on the microstructure regulation of alumina fibers was revealed.

Similar content being viewed by others

References

Hay RS, Armani CJ, Ruggles-Wrenn MB, Fair GE (2014) Creep mechanisms and microstructure evolution of NextelTM 610 fiber in air and steam. J Eur Ceram Soc 34(10):2413–2426. https://doi.org/10.1016/j.jeurceramsoc.2014.01.032

Armani CJ, Ruggles-Wrenn MB, Hay RS, Fair GE (2013) Creep and microstructure of NextelTM 720 fiber at elevated temperature in air and in steam. Acta Mater 61(16):6114–6124. https://doi.org/10.1016/j.actamat.2013.06.053

Almeida RSM, Bergmueller EL, Eggert BGF, Tushtev K, Schumacher T, Luehrs H, Clauss B, Grathwohl G, Rezwan K (2016) Thermal exposure effects on the strength and microstructure of a novel mullite fiber. J Am Ceram Soc 99(5):1709–1716. https://doi.org/10.1111/jace.14093

Armani CJ, Ruggles-Wrenn MB, Hay RS, Fair GE, Keller KA (2014) Creep of polycrystalline yttrium aluminum garnet (YAG) at elevated temperature in air and in steam. Mater Sci Eng, A 589:125–131. https://doi.org/10.1016/j.msea.2013.09.083

Hay RS, Fair GE, Tidball T (2015) Fiber strength after grain growth in NextelTM 610 alumina fiber. J Am Ceram Soc 98(6):1907–1914. https://doi.org/10.1111/jace.13523

Hay RS, Fair GE, Keller KA, Tidball T (2015) Determination of 3-D alumina grain orientation, size, shape, and growth kinetics from 2-D data in NextelTM 610 fibers. J Am Ceram Soc 98(7):2295–2306. https://doi.org/10.1111/jace.13572

Wilson DM, Visser LR (2001) High performance oxide fibers for metal and ceramic composites. Compos Part A 32(8):1143–1153. https://doi.org/10.1016/s1359-835x(00)00176-7

Bunsell AR, Berger MH (2000) Fine diameter ceramic fibres. J Eur Ceram Soc 20(13):2249–2260. https://doi.org/10.1016/s0955-2219(00)00090-x

Liu L, Wang J, Ma Y, Liu W, Yao S (2020) Preparation of continuous alumina fiber with nano grains by the addition of iron sol. Materials 13(23). https://doi.org/10.3390/ma13235442

Venkatesh R, Ramanan SR (2000) Effect of organic additives on the properties of sol-gel spun alumina fibres. J Eur Ceram Soc 20(14-15):2543–2549

Pfeifer S, Bischoff M, Niewa R, Clauss B, Buchmeiser MR (2014) Structure formation in yttrium aluminum garnet (YAG) fibers. J Eur Ceram Soc 34(5):1321–1328. https://doi.org/10.1016/j.jeurceramsoc.2013.10.036

Ma X, Lv Z, Tan H, Wang C, Li L, Wang Y (2019) Preparation of YAG nano-fibers using polyvinyl butyral from nitrate solution. J Phys Chem Solids 130:276–281. https://doi.org/10.1016/j.jpcs.2019.02.029

Xie Y, Wang L, Ma D, Peng Y, Zhu L, Wang X, Zhang G, Wang T, Jia Z, Zhang J (2019) Preparation, mechanical properties, and diffuse reflectance of YAG continuous fibers and nanofibers. Ceram Int 45(17):21213–21219. https://doi.org/10.1016/j.ceramint.2019.07.102

Jiang J, Ni N, Hao W, Zhao X, Guo F, Fan X, Xiao P (2019) Effects of sintering atmosphere on the densification and microstructure of yttrium aluminum garnet fibers prepared by sol-gel process. J Eur Ceram Soc 39(16):5332–5337. https://doi.org/10.1016/j.jeurceramsoc.2019.08.033

Gao Y, Cheng M, Liu Q, Li C, Liu J, Yao S, Wang J, Ma Y, Liu W (2019) Thermal decomposition of aluminum carboxylates based precursor for alumina fibers. Mater Res Express 6(11). https://doi.org/10.1088/2053-1591/ab4ab1

Song X, Gao Y, Liu Q, Wang J, Yao S, Liu W, Ma Y, Cai Q (2019) Thermally stable boron-containing mullite fibers derived from a monophasic mullite sol. Ceram Int 45(1):1171–1178. https://doi.org/10.1016/j.ceramint.2018.09.301

Liang C, Liu W, Liu Q, Gao Y, Liu J, Wang J, Yao S, Ma Y (2021) The formation of core-sheath structure and its effects on thermal decomposition and crystallization of alumina fibers. Ceram Int 47(4):5145–5155. https://doi.org/10.1016/j.ceramint.2020.10.092

Pfeifer S, Demirci P, Duran R, Stolpmann H, Renfftlen A, Nemrava S, Niewa R, Clauss B, Buchmeiser MR (2016) Synthesis of zirconia toughened alumina (ZTA) fibers for high performance materials. J Eur Ceram Soc Soc 36(3):725–731. https://doi.org/10.1016/j.jeurceramsoc.2015.10.028

Lucuta PG, Halliday JD, Christian B (1992) Phase evolution in Al2O3 fibre prepared from an oxychloride precursor. J Mater Sci 27(22):6053–6061. https://doi.org/10.1007/BF01133749

Zhao Z, Shen X, Yao H, Wang J, Chen J, Li Z (2014) Alumina nanofibers obtained via electrospinning of pseudo-boehmite sol/PVP solution. J Sol-Gel Sci Technol 70(1):72–80. https://doi.org/10.1007/s10971-014-3276-x

Hafid Roque-Ruiz J, Medellin-Castillo NA, Yobanny Reyes-Lopez S (2019) Fabrication of α-alumina fibers by sol-gel and electrospinning of aluminum nitrate precursor solutions. Results Phys 12:193–204. https://doi.org/10.1016/j.rinp.2018.11.068

Nordahl CS, Messing GL (2002) Sintering of α-Al2O3-seeded nanocrystalline γ-Al2O3 powders. J Eur Ceram Soc 22(4):415–422. https://doi.org/10.1016/s0955-2219(01)00285-0

Schmuecker M, Flucht F, Mechnich P (2012) Degradation of oxide fibers by thermal overload and environmental effects. Mater Sci Eng A 557:10–16. https://doi.org/10.1016/j.msea.2012.05.107

Li X, Xu H, Wang Q, Li S, Xiao H, Zhang L, Tang M, Chen L (2019) Control of continuous α-Al2O3 fibers by self-seeding and SiO2-Sol doping. Ceram Int 45(9):12053–12059. https://doi.org/10.1016/j.ceramint.2019.03.101

Li X, Su X, Xiao H, Chen L, Li S, Tang M (2020) Continuous α-Al2O3 fibers grown by seeding with in-situ suspension. Ceram Int 46(10):15638–15645. https://doi.org/10.1016/j.ceramint.2020.03.112

Almeida RSM, Tushtev K, Clauss B, Grathwohl G, Rezwan K (2015) Tensile and creep performance of a novel mullite fiber at high temperatures. Compos Part A 76:37–43. https://doi.org/10.1016/j.compositesa.2015.05.013

Poulon-Quintin A, Berger MH, Bunsell AR (2004) Mechanical and microstructural characterisation of Nextel 650 alumina-zirconia fibres. J Eur Ceram Soc 24(9):2769–2783. https://doi.org/10.1016/j.jeurceramsoc.2003.08.011

Chen IW, Wang XH (2000) Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 404(6774):168

Li JG, Ye YP (2006) Densification and grain growth of Al2O3 nanoceramics during pressureless sintering. J Am Ceram Soc 89(1):139–143. https://doi.org/10.1111/j.1551-2916.2005.00654.x

Li C, Liu W, Luo T, Cheng M, Liu Q, Wang J, Yao S, Ma Y (2021) Effect of formic-acid-to-acetic-acid ratio on the structure and spinnability of aqueous aluminium sol of alumina fibre. Ceram Int 47(18):26034–26041. https://doi.org/10.1016/j.ceramint.2021.06.009

Cheng M, Liu W, Yao S, Wang J, Ma Y (2021) Comparing the phase transformation of continuous alumina fiber and xerogels derived from the same precursor. J Sol-Gel Sci Technol 99(1):169–177. https://doi.org/10.1007/s10971-021-05572-4

Liu J, Ma Y, Liu W, Song X, Yao S, Wang J, Cheng M, Li C (2019). Preparation of alumina precursor sols with a high solid content for alumina fibers. Mater Res Express 6(4). https://doi.org/10.1088/2053-1591/aafcbf

Wu L-Y, Tong S-R, Hou S-Q, Ge M-F (2012) Influence of temperature on the heterogeneous reaction of formic acid on α-Al2O3. J Phys Chem A 116(42):10390–10396. https://doi.org/10.1021/jp3073393

Xue M, Gao B, Li R, Sun J (2018) Aluminum formate (AF): synthesis, characterization and application in dye wastewater treatment. J Environ Sci 74:95–106. https://doi.org/10.1016/j.jes.2018.02.013

Gao Y, Liu W, Song X, Liu Q, Yao S, Wang J, Cai Q, Ma Y (2019) Preparation, characterization and mechanical properties of continuous mullite fibers derived from the diphasic sol-gel route. J Sol-Gel Sci Technol 92(1):75–83. https://doi.org/10.1007/s10971-019-05078-0

Venkatesh R, Ramanan SR (2002) Influence of processing variables on the microstructure of sol-gel spun alumina fibres. Mater Lett 55(3):189–195. https://doi.org/10.1016/s0167-577x(01)00644-9

Gutiérrez G, Johansson B (2002) Molecular dynamics study of structural properties of amorphous Al2O3. Phys Rev B 65(10):104202. https://doi.org/10.1103/PhysRevB.65.104202

Levin I, Brandon D (1998) Metastable alumina polymorphs: crystal structures and transition sequences. J Am Ceram Soc 81(8):1995–2012. https://doi.org/10.1111/j.1151-2916.1998.tb02581.x

Kwon S, Messing GL (2000) Sintering of mixtures of seeded boehmite and ultrafine α-alumina. J Am Ceram Soc 83(1):82–88. https://doi.org/10.1111/j.1151-2916.2000.tb01152.x

Acknowledgements

This work was supported by the National Nature Science Foundation of China (Grant no. U20A20240) and the Natural Science Foundation of Hunan Province (Grant no. 2021JJ40769, 2020JJ5733).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Y., Peng, S., Liu, W. et al. Preparation of a dense alumina fiber with nanograins by a novel two-step calcination. J Sol-Gel Sci Technol 103, 125–138 (2022). https://doi.org/10.1007/s10971-022-05813-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05813-0