Abstract

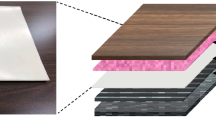

The building sector is known to make a large contribution to total energy consumption and CO2 emissions. Phase change materials (PCMs) have been considered for thermal energy storage (TES) in buildings. They can balance out the discrepancies between energy demand and energy supply, which are temporally out of phase. However, traditional PCMs need special latent storage devices or containers to encapsulate the PCM, in order to store and release the latent heat of the PCM. The proper design of TES systems using a PCM requires quantitative information and knowledge about the heat transfer and phase change processes in the PCM. In Korea, radiant floor heating systems, which have traditionally been used in residential buildings, consume approximately 55% of the total residential building energy consumption in heating. This article reviews the development of available latent heat thermal energy storage technologies and discusses PCM application methods for residential building using radiant floor heating systems with the goal of reducing energy consumption.

Similar content being viewed by others

References

Pérez-Lombard L, Ortiz J, Pout C. A review on buildings energy consumption information. Energy Build. 2008;40:394–8.

Ardente F, Beccali M, Cellura M, Mistretta M. Building energy performance: a LCA case study of kenaf-fibres insulation board. Energy Build. 2008;40:1–10.

Zabalza Bribián I, Aranda Usón A, Scarpellini S. Life cycle assessment in buildings: state-of-the-art and simplified LCA methodology as a complement for building certification. Build Environ. 2009;44:2510–20.

Levermore GJ. A review of the IPCC assessment report four, part 1: the IPCC process and greenhouse gas emission trends from buildings worldwide. Build Serv Eng Res Technol. 2008;29:349–61.

Kwok AG, Rajkovich NB. Addressing climate change in comfort standards. Build Environ. 2010;45:18–22.

Zalba B, Marín JM, Cabeza LF, Mehling H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl Therm Eng. 2003;23:251–83.

Alkan C, Sari A. Fatty acid/poly(methyl methacrylate) (PMMA) blends as form-stable phase change materials for latent heat thermal energy storage. Sol Energy. 2008;82:118–24.

Kenisarin M, Mahkamov K. Solar energy storage using phase change materials. Renew Sustain Energy Rev. 2007;11:1913–65.

Kim S, Drzal LT. High latent heat storage and high thermal conductive phase change materials using exfoliated graphite nanoplatelets. Sol Energy Mater Sol Cells. 2009;93:136–42.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev. 2009;13:318–45.

Tae S, Shin S. Current work and future trends for sustainable buildings in South Korea. Renew Sustain Energy Rev. 2009;13:1910–21.

Regin AF, Solanki SC, Saini JS. Heat transfer characteristics of thermal energy storage system using PCM capsules: a review. Renew Sustain Energy Rev. 2008;12:2438–58.

Abhat A. Low temperature latent heat thermal energy storage: heat storage materials. Sol Energy. 1983;30:313–32.

Tyagi VV, Buddhi D. PCM thermal storage in buildings: a state of art. Renew Sustain Energy Rev. 2007;11:1146–66.

Khudhair AM, Farid MM. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers Manag. 2004;45:263–75.

Hong K, Park S. Melamine resin microcapsules containing fragrant oil: synthesis and characterization. Mater Chem Phys. 1999;58:128–31.

Nelson G. Application of microencapsulation in textiles. Int J Pharm. 2002;242:55–62.

Zhang XX, Fan YF, Tao XM, Yick KL. Fabrication and properties of microcapsules and nanocapsules containing n-octadecane. Mater Chem Phys. 2004;88:300–7.

Lan X, Tan Z, Zou G, Sun L, Zhang T. Microencapsulation of n-eicosane as energy storage material. Chin J Chem. 2004;22:411–4.

Li W, Zhang X, Wang X, Niu J. Preparation and characterization of microencapsulated phase change material with low remnant formaldehyde content. Mater Chem Phys. 2007;106:437–42.

Wang X, Niu J, van Paassen AHC. Raising evaporative cooling potentials using combined cooled ceiling and MPCM slurry storage. Energy Build. 2008;40:1691–8.

Diaconu BM. Transient thermal response of a PCS heat storage system. Energy Build. 2009;41:212–9.

Alkan C, Sarı A, Karaipekli A, Uzun O. Preparation, characterization, and thermal properties of microencapsulated phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2009;93:143–7.

Lai C, Chen RH, Lin C. Heat transfer and thermal storage behavior of gypsum boards incorporating micro-encapsulated PCM. Energy Build. 2010;42:1259–66.

Veerappan M, Kalaiselvam S, Iniyan S, Goic R. Phase change characteristic study of spherical PCMs in solar energy storage. Sol Energy. 2009;83:1245–52.

Bayés-García L, Ventolà L, Cordobilla R, Benages R, Calvet T, Cuevas-Diarte MA. Phase change materials (PCM) microcapsules with different shell compositions: Preparation, characterization and thermal stability. Sol Energy Mater Sol Cells. 2010;94:1235–40.

Hawlader MNA, Uddin MS, Khin MM. Microencapsulated PCM thermal-energy storage system. Appl Energy. 2003;74:195–202.

Zou GL, Tan ZC, Lan XZ, Sun LX, Zhang T. Preparation and characterization of microencapsulated hexadecane used for thermal energy storage. Chin Chem Lett. 2004;15:729–32.

Liang C, Lingling X, Hongbo S, Zhibin Z. Microencapsulation of butyl stearate as a phase change material by interfacial polycondensation in a polyurea system. Energy Convers Manag. 2009;50:723–9.

Kim EY, Kim HD. Preparation and properties of microencapsulated octadecane with waterborne polyurethane. J Appl Polym Sci. 2005;96:1596–604.

Shin Y, Yoo D, Son K. Development of thermoregulating textile materials with microencapsulated phase change materials (PCM). IV. Performance properties and hand of fabrics treated with PCM microcapsules. J Appl Polym Sci. 2005;97:910–915.

Su J, Wang L, Ren L. Preparation and characterization of double-MF shell microPCMs used in building materials. J Appl Polym Sci. 2005;97:1755–62.

Zhang X, Fan Y, Tao X, Yick K. Crystallization and prevention of supercooling of microencapsulated n-alkanes. J Colloid Interface Sci. 2005;281:299–306.

Zhang P, Hu Y, Song L, Ni J, Xing W, Wang J. Effect of expanded graphite on properties of high-density polyethylene/paraffin composite with intumescent flame retardant as a shape-stabilized phase change material. Sol Energy Mater Sol Cells. 2010;94:360–5.

Xu X, Zhang Y, Lin K, Di H, Yang R. Modeling and simulation on the thermal performance of shape-stabilized phase change material floor used in passive solar buildings. Energy Build. 2005;37:1084–91.

Lin K, Zhang Y, Xu X, Di H, Yang R, Qin P. Experimental study of under-floor electric heating system with shape-stabilized PCM plates. Energy Build. 2005;37:215–20.

Zhang YP, Lin KP, Yang R, Di HF, Jiang Y. Preparation, thermal performance and application of shape-stabilized PCM in energy efficient buildings. Energy Build. 2006;38:1262–9.

Cheng W, Zhang R, Xie K, Liu N, Wang J. Heat conduction enhanced shape-stabilized paraffin/HDPE composite PCMs by graphite addition: preparation and thermal properties. Sol Energy Mater Sol Cells. 2010;94:1636–42.

Alkan C, Sarı A, Karaipekli A. Preparation, thermal properties and thermal reliability of microencapsulated n-eicosane as novel phase change material for thermal energy storage. Energy Convers Manag. 2011;52:687–92.

Koschenz M, Lehmann B. Development of a thermally activated ceiling panel with PCM for application in lightweight and retrofitted buildings. Energy Build. 2004;36:567–78.

Shilei L, Neng Z, Guohui F. Impact of phase change wall room on indoor thermal environment in winter. Energy Build. 2006;38:18–24.

De Grassi M, Carbonari A, Palomba G. A statistical approach for the evaluation of the thermal behavior of dry assembled PCM containing walls. Build Environ. 2006;41:448–85.

Carbonari A, De Grassi M, Di Perna C, Principi P. Numerical and experimental analyses of PCM containing sandwich panels for prefabricated walls. Energy Build. 2006;38:472–83.

Darkwa K, O’Callaghan PW. Simulation of phase change drywalls in a passive solar building. Appl Therm Eng. 2006;26:853–8.

Huang MJ, Eames PC, Hewitt NJ. The application of a validated numerical model to predict the energy conservation potential of using phase change materials in the fabric of a building. Sol Energy Mater Sol Cells. 2006;90:1951–60.

Zhou G, Zhang Y, Wang X, Lin K, Xiao W. An assessment of mixed type PCM-gypsum and shape-stabilized PCM plates in a building for passive solar heating. Sol Energy. 2007;81:1351–60.

Castellón C, Medrano M, Roca J, Cabeza LF, Navarro ME, Fernández AI, Lázaro A, Zalba B. Effect of microencapsulated phase change material in sandwich panels. Renew Energy. 2010;35:2370–4.

Ahmad M, Bontemps A, Sallée H, Quenard D. Thermal testing and numerical simulation of a prototype cell using light wallboards coupling vacuum isolation panels and phase change material. Energy Build. 2006;38:673–81.

Darkwa J, Zhou T. Enhanced laminated composite phase change material for energy storage. Energy Convers Manag. 2011;52:810–5.

Kuznik F, Virgone J, Roux J. Energetic efficiency of room wall containing PCM wallboard: a full-scale experimental investigation. Energy Build. 2008;40:148–56.

Halawa E, Bruno F, Saman W. Numerical analysis of a PCM thermal storage system with varying wall temperature. Energy Convers Manag. 2005;46:2592–604.

Weinläder H, Beck A, Fricke J. PCM-facade-panel for daylighting and room heating. Sol Energy. 2005;78:177–86.

Cabeza LF, Castellón C, Nogués M, Medrano M, Leppers R, Zubillaga O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007;39:113–9.

Xiao W, Wang X, Zhang Y. Analytical optimization of interior PCM for energy storage in a lightweight passive solar room. Appl Energy. 2009;86:2013–8.

Zhou G, Yang Y, Wang X, Zhou S. Numerical analysis of effect of shape-stabilized phase change material plates in a building combined with night ventilation. Appl Energy. 2009;86:52–9.

Park BI, Seok HT, Kim K-W. The historical changes of ONDOL. Korean J Air Cond Refrig Eng. 1995;24:613–27.

Song G. Buttock responses to contact with finishing materials over the ONDOL floor heating system in Korea. Energy Build. 2005;37:65–75.

Song G. The status of the automatic control systems for ONDOL. Korean J Air Cond Refrig Eng. 1996;25:323–33.

Kim S, Kim H. Thermal stability and viscoelastic properties of MF/PVAc hybrid resins on the adhesion for engineered flooring in under heating system; ONDOL. Thermochim Acta. 2006;444:134–40.

Acknowledgements

This study was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government(MEST) (No. 2011-0016996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeon, J., Lee, JH., Seo, J. et al. Application of PCM thermal energy storage system to reduce building energy consumption. J Therm Anal Calorim 111, 279–288 (2013). https://doi.org/10.1007/s10973-012-2291-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2291-9