Abstract

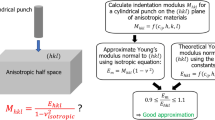

In this paper, the application of a recently formulated two-step Bayesian framework to the estimation of effective anisotropic elastic constants of single plies within a multi-laminate polymer matrix composite is demonstrated, while using previously reported spherical indentation measurements within singular plies. Experimental spherical indentation measurements within the epoxy/fiber plies are inherently noisy due to local variation of the fiber volume fraction underneath the indenter. This paper demonstrates that the usage of a two-step Bayesian framework enables the extraction of reliable point estimates (and associated distributions) for the effective elastic constants from indentation modulus measurements conducted within single plies at different angles to the fiber orientations. The first step of the two-step Bayesian framework establishes the effective elastic indentation modulus of a single ply as a function of its intrinsic elastic stiffness parameters and the angle between the indentation direction and the fiber orientation using a database of suitable finite element simulations. The second step involves the calibration of the indentation measurements from a given set of multi-laminate samples to the reduced-order model established in the first step. The second step is accomplished by sampling the posterior distribution of the single ply elastic parameters via Monte Carlo Markov Chain methods. This new framework is demonstrated in this study for an IM7/977-3 carbon fiber/epoxy multi-laminate sample.

Similar content being viewed by others

References

Koronis G, Silva A, Fontul M (2013) Green composites: a review of adequate materials for automotive applications. Compos B 44(1):120–127. https://doi.org/10.1016/j.compositesb.2012.07.004

Soutis C (2005) Fibre reinforced composites in aircraft construction. Prog Aerosp Sci 41(2):143–151. https://doi.org/10.1016/j.paerosci.2005.02.004

Hollaway LC (2010) A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr Build Mater 24(12):2419–2445. https://doi.org/10.1016/j.conbuildmat.2010.04.062

Mouritza AP, Bannister MK, Falzonb PJ, Leongb KH (1999) Review of applications for advanced three-dimensional fibre textile composites. Compos A Appl Sci Manuf 30:1445–1461

Reddy JN, Miravete A (2018) Practical analysis of composite laminates. CRC Press, Boca Raton

Chamis CC (1989) Mechanics of composite-materials—past, present, and future. J Compos Technol Res 11(1):3–14

Kalidindi SR, Franco E (1997) Numerical evaluation of isostrain and weighted-average models for elastic moduli of three-dimensional composites. Compos Sci Technol 57(3):293–305

Pastore C, Gowayed Y (2008) 6—Structure and mechanics of 2D and 3D textile composites. In: Schwartz P (ed) Structure and mechanics of textile fibre assemblies. Woodhead Publishing, Cambridge, pp 141–189. https://doi.org/10.1533/9781845695231.141

Kregers AF, Melbardis YG (1978) Determination of the deformability of three-dimensionally reinforced composites by the stiffness averaging method. Polym Mech 14(1):1–5. https://doi.org/10.1007/BF00859550

Ishikawa T, Chou TW (1982) Stiffness and strength behaviour of woven fabric composites. J Mater Sci 17(11):3211–3220. https://doi.org/10.1007/BF01203485

Reddy JN (2003) Mechanics of laminated composite plates and shells: theory and analysis. CRC Press, Boca Raton

Barbero E, Reddy J (1990) Nonlinear analysis of composite laminates using a generalized laminated plate theory. AIAA J 28(11):1987–1994

Flaggs DK, Kural MH (1982) Experimental determination of the in situ transverse lamina strength in graphite/epoxy laminates. J Compos Mater 16:103–116

Huang ZM (2001) Simulation of the mechanical properties of fibrous composites by the bridging micromechanics model. Compos Part A Appl Sci 32(2):143–172. https://doi.org/10.1016/S1359-835x(00)00142-1

Kalidindi SR, Abusafieh A (1996) Longitudinal and transverse moduli and strengths of low angle 3-D braided composites. J Compos Mater 30(8):885–905

Engelstad S, Reddy J (1993) Probabilistic nonlinear finite element analysis of composite structures. AIAA J 31(2):362–369

Hardiman M, Vaughan TJ, McCarthy CT (2017) A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos Struct 180:782–798. https://doi.org/10.1016/j.compstruct.2017.08.004

Hodzic A, Kalyanasundaram S, Kim JK, Lowe AE, Stachurski ZH (2001) Application of nano-indentation, nano-scratch and single fibre tests in investigation of interphases in composite materials. Micron 32(8):765–775. https://doi.org/10.1016/S0968-4328(00)00084-6

Vlassak JJ, Nix WD (1994) Measuring the elastic properties of anisotropic materials by means of indentation experiments. J Mech Phys Solids 42(8):1223–1245. https://doi.org/10.1016/0022-5096(94)90033-7

Unnikrishnan GU, Unnikrishnan VU, Reddy JN (2006) Constitutive material modeling of cell: a micromechanics approach. J Biomech Eng 129(3):315–323. https://doi.org/10.1115/1.2720908

Pathak S, Stojakovic D, Kalidindi SR (2009) Measurement of the local mechanical properties in polycrystalline samples using spherical nanoindentation and orientation imaging microscopy. Acta Mater 57(10):3020–3028. https://doi.org/10.1016/j.actamat.2009.03.008

Weaver JS, Priddy MW, McDowell DL, Kalidindi SR (2016) On capturing the grain-scale elastic and plastic anisotropy of alpha-Ti with spherical nanoindentation and electron back-scattered diffraction. Acta Mater 117:23–34

Khosravani A, Morsdorf L, Tasan CC, Kalidindi SR (2018) Multiresolution mechanical characterization of hierarchical materials: spherical nanoindentation on martensitic Fe–Ni–C steels. Acta Mater 153:257–269. https://doi.org/10.1016/j.actamat.2018.04.063

Pathak S, Kalidindi SR, Mara NA (2016) Investigations of orientation and length scale effects on micromechanical responses in polycrystalline zirconium using spherical nanoindentation. Scr Mater 113:241–245. https://doi.org/10.1016/j.scriptamat.2015.10.035

Pathak S, Kalidindi SR (2015) Spherical nanoindentation stress–strain curves. Mater Sci Eng R Rep 91:1–36

Castillo AR, Kalidindi SR (2019) A Bayesian framework for the estimation of the single crystal elastic parameters from spherical indentation stress–strain measurements. Front Mater 6:136

Patel DK, Al-Harbi HF, Kalidindi SR (2014) Extracting single-crystal elastic constants from polycrystalline samples using spherical nanoindentation and orientation measurements. Acta Mater 79:108–116. https://doi.org/10.1016/j.actamat.2014.07.021

Patel D, Kalidindi S (2017) Estimating the slip resistance from spherical nanoindentation and orientation measurements in polycrystalline samples of cubic metals. Int J Plast 92:19

Rossi A, Castillo A, Przybyla C, Kalidindi SR (2019) Study of local mechanical responses in an epoxy-carbon fiber laminate composite using spherical indentation stress-strain. integrating materials and manufacturing innovation (accepted)

Hertz H (1896) Miscellaneous papers. MacMillan and Co., Ltd., New York, p 146

Haario H, Saksman E, Tamminen J (2005) Componentwise adaptation for high dimensional MCMC. Comput Stat 20(2):265–273. https://doi.org/10.1007/BF02789703

Gelman A, Carlin J, Stern H, Dunson D, Vehtari A, Rubin D (2014) Bayesian data analysis, 3rd edn. Texts in statistical science. Chapman and Hall/CRC, Boca Raton

Roberts GO, Gelman A, Gilks WR (1997) Weak convergence and optimal scaling of random walk metropolis algorithms. Ann Appl Probab 7(1):110–120. https://doi.org/10.1214/aoap/1034625254

MacKay DJC (1992) Bayesian interpolation. Neural Comput 4(3):415–447. https://doi.org/10.1162/neco.1992.4.3.415

Bunge HJ (1993) Texture analysis in materials science. Mathematical methods (trans: Morris PR). Cuvillier Verlag, Göttingen

Kalidindi SR, Pathak S (2008) Determination of the effective zero-point and the extraction of spherical nanoindentation stress-strain curves. Acta Mater 56(14):3523–3532. https://doi.org/10.1016/j.actamat.2008.03.036

Barlat F, Maeda Y, Chung K, Yanagawa M, Brem JC, Hayashida Y, Lege DJ, Matsui K, Murtha SJ, Hattori S, Becker RC, Makosey S (1997) Yield function development for aluminum alloy sheets. J Mech Phys Solids 45(11):1727–1763. https://doi.org/10.1016/S0022-5096(97)00034-3

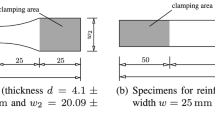

Clay SB, Knoth PM (2016) Experimental results of quasi-static testing for calibration and validation of composite progressive damage analysis methods. J Compos Mater 51(10):1333–1353. https://doi.org/10.1177/0021998316658539

Kaddour AS, Hinton MJ (2012) Input data for test cases used in benchmarking triaxial failure theories of composites. J Compos Mater 46(19–20):2295–2312. https://doi.org/10.1177/0021998312449886

Joseph VR, Gul E, Ba S (2015) Maximum projection designs for computer experiments. Biometrika 102(2):371–380

ABAQUS (2014) 6.14 Dassault Systémes Simulia Corp. Providence, RI

Christopher MB (2006) Pattern recognition and machine learning. Springer, New York

Ranganathan SI, Ostoja-Starzewski M (2008) Universal elastic anisotropy index. Phys Rev Lett 101(5):055504. https://doi.org/10.1103/PhysRevLett.101.055504

Sobol′ IM (2001) Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math Comput Simul 55(1):271–280. https://doi.org/10.1016/S0378-4754(00)00270-6

Castillo AR, Joseph VR, Kalidindi SR (2019) Bayesian sequential design of experiments for extraction of single-crystal material properties from spherical indentation measurements on polycrystalline samples. JOM 71:2671–2679

Staab GH (1999) 6—Laminate analysis. In: Staab GH (ed) Laminar composites. Butterworth-Heinemann, Woburn, pp 191–282. https://doi.org/10.1016/B978-075067124-8/50006-0

Khdeir AA, Reddy JN (1989) Exact solutions for the transient response of symmetric cross-ply laminates using a higher-order plate theory. Compos Sci Technol 34(3):205–224. https://doi.org/10.1016/0266-3538(89)90029-8

ASTM D (2008) Standard test method for tensile properties of polymer matrix composite materials

Caflisch RE (1998) Monte Carlo and quasi-Monte Carlo methods. Acta Numer 7:1–49. https://doi.org/10.1017/S0962492900002804

Acknowledgements

The authors acknowledge support from ONR Grant N00014-18-1-2879.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Additional information

In honor of Professor J.N. Reddy for his 75th Birthday.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Castillo, A.R., Kalidindi, S.R. Bayesian estimation of single ply anisotropic elastic constants from spherical indentations on multi-laminate polymer-matrix fiber-reinforced composite samples. Meccanica 56, 1575–1586 (2021). https://doi.org/10.1007/s11012-020-01154-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-020-01154-w