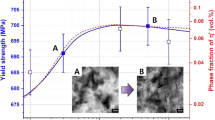

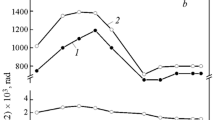

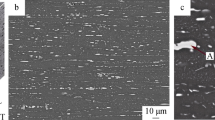

Novel aluminum powder alloys with graded density are studied by differential scanning calorimetry, x-ray diffraction, fractographic, and x-ray phase analyses. The influence of solution treatment and aging on the microstructure and properties of the alloys is investigated. The variation of properties over the thickness of the specimens is determined. It is shown that the mechanical properties are the best after a 2-h solution treatment at 495°C and subsequent 8-h aging at 190°C with air cooling.

Similar content being viewed by others

References

C. H. Thai, A. J. M. Ferreira, and H. Nguyen-Xuan, “Isogeometric analysis of size dependent isotropic and sandwich functionally graded microplates based on modified strain gradient elasticity theory,” Compos. Struct., 192, 274 – 288 (2018).

M. Naebe and K. Shirvanimoghaddam, “Functionally graded materials: A review of fabrication and properties,” Appl. Mater. Today, 5, 223 – 245 (2016).

C. Zhou, L. Li, J. Wang, J. Yi, and Y. Peng, “A novel approach for fabrication of functionally gradedW/Cu composites via microwave processing,” J. Alloys Compd., 743, 383 – 387 (2018).

J. Reddy and J. Kim, “A nonlinear modified couple stress-based third-order theory of functionally graded plates,” Compos. Struct., 94, 1128 – 1143 (2012).

S. A. Momeni and M. Asghari, “The second strain gradient functionally graded beam formulation,” Compos. Struct., 188, 15 – 24 (2018).

X. Xiang, X. L. Wang, G. K. Zhang, T. Tang, and X. C. Lai, “Preparation technique and alloying effect of aluminide coatings as tritium permeation barriers: A review,” Int. J. Hydrogen Energ., 40, 3697 – 3707 (2015).

L. J. Xue, H. Z. Mu, and J. J. Feng, “Thermal mechanical behavior of a functionally graded shape memory alloy cylinder subject to pressure and graded temperature loads,” J. Mater. Res., 33, 1806 – 1812 (2018).

M. Shaik, A. K. Khanra, and B. P. Saha, “Processing of sintered and CVD coated SiC/CNFs thin composite tubes,” Mater. Chem. Phys., 220, 225 – 232 (2018).

S. Y. He, Y. Zhang, G. Dai, and J. Q. Jiang, “Preparation of density-graded aluminum foam,” Mater. Sci. Eng. A, 618, 496 – 499 (2018).

C. Liu, Y. Liu, Y. L. Yang, Y. Z., et al., “New method for preparing micron porous aluminum via powder metallurgy,” Mater. Sci. Tech-load., 34, 1295 – 1302 (2018).

M. Ubeyli, E. Balci, B. Sarikan, et al., “The ballistic performance of SiC–AA7075 functionally graded composite produced by powder metallurgy,” Mater. Des., 56, 31 – 36 (2014).

C. Liu, Y. Liu, C. P. Liang, et al., “Novel approach for fabrication and characterization of porosity-graded material,” Mater. Sci. Tech-load., 35, 1583 – 1591 (2019).

A. Albiter, C. A. León, and R. A. L. Drew, “Microstructure and heat-treatment response of Al-2Al2/TiC composites,” Mater. Sci. Eng. A, 289, 109 – 115 (2000).

M. Taherishargh, I. V. Belova, G. E. Murch, and T. Fiedler, “On the mechanical properties of heat-treated expanded perlite–aluminium syntactic foam,” Mater. Des., 63, 375 – 383 (2014).

D. Lehmhus, C. Marschner, and J. Banhart, “Influence of heat treatment on compression fatigue of aluminum foams,” J. Mater. Sci., 37, 3447 – 3451 (2002).

M. S. Musa, G. Maric, and K. Grilec, “Nanoindentation of closed cell Al alloy foams subjected to different heat treatment regimes,” Compos., Part B, 89, 383 – 387 (2016).

Z. H. Wang, Z. Q. Li, and J. G. Ning, “Effect of heat treatments on the crushing behaviour and energy absorbing performance of aluminum alloy foams,” Mater. Des., 30, 977 – 982 (2009).

F. Campana and D. Pilone, “Effect of heat treatments on the mechanical behavior of aluminum alloy foams,” Scr. Mater., 60, 679 – 682 (2009).

J. Lázaro, E. Solórzano, M. A. Rodríguez-Pérez, et al., “Heat treatment of aluminum foam precursors: effects on foam expansion and final cellular structure,” Pro. Mater. Sci., 4, 287 – 292 (2014).

R. A. C. Daniel and E. Shahrzad, “Prediction of the effect of artificial aging heat treatment on the yield strength of an open-cell aluminum foam,” J. Mater. Sci., 43, 1121 – 1127 (2008).

I. Alfonso, G. Lara, G. González, et al., “A novel solid state method for manufacturing Al foams by over solution heat treatment,” Mater. Lett., 174, 6 – 9 (2016).

P. Schüler, R. Frank, D. Uebel, et al., “Influence of heat treatments on the microstructure and mechanical behaviour of open cell AlSi7Mg0.3 foams on different lengthscales,” Acta Mater., 109, 32 – 45 (2016).

I. Alfonso, C. Maldonado, G. Gonzalez, and A. Bedolla, “Effect of Mg content and solution treatment on the microstructure of Al – Si – Cu – Mg alloys,” J. Mater. Sci., 41, 1945 – 1952 (2006).

F. Saba, F. M. Zhang, S. L. Liu, and T. F. Liu, “Reinforcement size dependence of mechanical properties and strengthening mechanisms in diamond reinforced titanium metal matrix composites,” Compos., Part B, 167, 7 – 19 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Notes. 1. The porosity of the powders is given in parentheses. 2. The numerators give the powder content in the alloy in mass percent; the dominators give it in atomic percent.

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 16 – 24, November, 2021.

Rights and permissions

About this article

Cite this article

Liu, C., Liu, Y., Wang, T. et al. Effects of Heat Treatment on the Microstructure and Properties of Graded-Density Powder Aluminum Alloys. Met Sci Heat Treat 63, 590–598 (2022). https://doi.org/10.1007/s11041-022-00734-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00734-9