Abstract

The dissolving of cellulose under harsh and environmentally unfavorable circumstances is the basis of traditional chemical methods for nanocellulose (NC) or derivatization. Due to the limitations of present methods for dissolving and processing NC, more efficient and ecologically acceptable solvents are required. Because of their excellent thermal and chemical stability, non-flammability, and miscibility with many other solvent systems, ionic liquids (ILs) have emerged as useful and environmentally friendly solvents. Meanwhile, another procedure for producing NC with homogeneous and extremely crystalline characteristics is ultra-sonification. Ultrasound energy is delivered to cellulose chains during ultrasonication by a process known as cavitation, which refers to the development, growth, and collapse of cavities in a liquid medium. Cavitation provides 10–100 kJ/mol of energy in this so-called sonochemistry, which is within the hydrogen bond energy scale. As a result, both catalytic IL treatments and ultrasonication influence the progressive disintegration of NC synthesis.

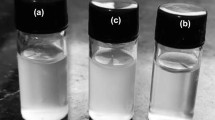

Graphical abstract

Similar content being viewed by others

Data availability

Available upon request.

The work described has not been published previously and that it is not under consideration for publication elsewhere. This publication is approved by all authors and tacitly or explicitly by the responsible authorities where the work was carried out. We also declare that, if accepted, it will not be published elsewhere in the same form, in English or in any other language, without the written consent of the Publisher. There is no conflict of interest for this paper.

References

Rebouillat S, Pla F (2013) State of the art manufacturing and engineering of NC: a review of available data and industrial applications. J Biomater Nanobiotechnol 4(2):1–24

Tang Y, Yang S, Zhang N, Zhang J (2014) Preparation and characterization of nanocrystalline cellulose via low-intensity ultrasonic-assisted sulfuric acid hydrolysis. Cellulose 21:335–346

Ioelovich M (2012) Optimal conditions for isolation of nanocrystalline cellulose particles. Nanosci Nanotechnol 2:9–13

Brinchi L, Cotana F, Fortunati E, Kenny J (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohyd Polym 94:154–169

Khalil HA, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohyd Polym 99:649–665

Torres FG, Commeaux S, Troncoso OP (2012) Biocompatibility of bacterial cellulose based biomaterials. J Funct Biomater 3:864–878

Peng BL, Dhar N, Liu H, Tam K (2011) Chemistry and applications of nanocrystalline cellulose and its derivatives: a nanotechnology perspective. Can J Chem Eng 89:1191–1206

Wu Q, Meng Y, Wang S, Li Y, Fu S, Ma L, Harper D (2014) Rheological behavior of cellulose nanocrystal suspension: influence of concentration and aspect ratio. J Appl Polym Sci 131(15):1–12

Araki J, Wada M, Kuga S (2001) Steric stabilization of a cellulose microcrystal suspension by poly (ethylene glycol) grafting. Langmuir 17:21–27

De Souza Lima MM, Wong JT, Paillet M, Borsali R, Pecora R (2003) Translational and rotational dynamics of rodlike cellulose whiskers. Langmuir 19:24–29

Kimura F, Kimura T, Tamura M, Hirai A, Ikuno M, Horii F (2005) Magnetic alignment of the chiral nematic phase of a cellulose microfibril suspension. Langmuir 21:2034–2037

Revol J-F (1982) On the cross-sectional shape of cellulose crystallites in Valonia ventricosa. Carbohyd Polym 2:123–134

Pranger L, Tannenbaum R (2008) Biobased nanocomposites prepared by in situ polymerization of furfuryl alcohol with cellulose whiskers or montmorillonite clay. Macromolecules 41:8682–8687

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J-L, Heux L, Dubreuil F, Rochas C (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromol 9:57–65

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromol 6:1048–1054

Dufresne A, Cavaillé JY, Helbert W (1997) Thermoplastic nanocomposites filled with wheat straw cellulose whiskers. Part II: effect of processing and modeling. Polym Compos 18:198–210

Lu P, Hsieh Y-L (2012) Preparation and characterization of cellulose nanocrystals from rice straw. Carbohyd Polym 87:564–573

Holilah H, Bahruji H, Ediati R, Asranudin A, Jalil AA, Piluharto B, Nugraha RE, Prasetyoko D (2022) Uniform rod and spherical nanocrystalline celluloses from hydrolysis of industrial pepper waste (Piper nigrum L.) using organic acid and inorganic acid. Int J Biol Macromol 204:593–605

Ilyas R, Sapuan S, Ishak M (2018) Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohyd Polym 181:1038–1051

Boschetti WTN, Carvalho AMML, de Càssia Oliveira Carneiro A, Vidaurre GB, Gomes FJB, Soratto DN (2021) Effect of mechanical treatment of eucalyptus pulp on the production of nanocrystalline and microcrystalline cellulose. Sustainability 13:5888

Nuruddin A, Habibullah A, Adipratama MJ, Purwasasmita BS (2021) Synthesis of barium hexaferrite templated by nanocrystalline cellulose extracted from luffa acutangula fiber. Mater Res Express 8:066104

Fortunati E, Puglia D, Monti M, Peponi L, Santulli C, Kenny J, Torre L (2013) Extraction of cellulose nanocrystals from Phormium tenax fibres. J Polym Environ 21:319–328

Singh S, Varanasi P, Singh P, Adams PD, Auer M, Simmons BA (2013) Understanding the impact of ILs pretreatment on cellulose and lignin via thermochemical analysis. Biomass Bioenerg 54:276–283

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13:171–180

Li R, Fei J, Cai Y, Li Y, Feng J, Yao J (2009) Cellulose whiskers extracted from mulberry: a novel biomass production. Carbohyd Polym 76:94–99

Johar N, Ahmad I, Dufresne A (2012) Ind Crops and Prod 37(1):93–99

Morais JPS, de Freitas Rosa M, Dias Nascimento L, Magalhães do Nascimento D, Ribeiro Cassales A (2013) Extraction and characterization of NC structures from raw cotton linter. Carbohydr Polym 91:229–235

Lamaming J, Hashim R, Leh CP, Sulaiman O (2017) Properties of cellulose nanocrystals from oil palm trunk isolated by total chlorine free method. Carbohyd Polym 156:409–416

Jiang F, Hsieh Y-L (2013) Chemically and mechanically isolated NC and their self-assembled structures. Carbohyd Polym 95:32–40

Mishra SP, Manent A-S, Chabot B, Daneault C (2012) Production of NC from native cellulose–various options utilizing ultrasound. BioResources 7:0422–0436

Xie J, Hse C-Y, Cornelis F, Hu T, Qi J, Shupe TF (2016) Isolation and characterization of cellulose nanofibers from bamboo using microwave liquefaction combined with chemical treatment and ultrasonication. Carbohyd Polym 151:725–734

Liu C-F, Ren J-L, Xu F, Liu J-J, Sun J-X, Sun R-C (2006) Isolation and characterization of cellulose obtained from ultrasonic irradiated sugarcane bagasse. J Agric Food Chem 54:5742–5748

Hachaichi A, Kouini B, Kian LK, Asim M, Fouad H, Jawaid M, Sain M (2021) Nanocrystalline cellulose from microcrystalline cellulose of date palm fibers as a promising candidate for bio-nanocomposites: isolation and characterization. Materials 14:5313

Doan TKQ, Chiang KY (2022) Characteristics and kinetics study of spherical cellulose nanocrystal extracted from cotton cloth waste by acid hydrolysis. Sustain Environ Res 32:1–14

Ilyas R, Sapuan S, Atikah M, Asyraf M, Rafiqah SA, Aisyah H, Nurazzi NM, Norrrahim M (2021) Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text Res J 91:152–167

Tingaut P, Zimmermann T, Sèbe G (2012) Cellulose nanocrystals and microfibrillated cellulose as building blocks for the design of hierarchical functional materials. J Mater Chem 22:20105–20111

Zhang J, Wang Y, Zhang L, Zhang R, Liu G, Cheng G (2014) Understanding changes in cellulose crystalline structure of lignocellulosic biomass during ILs pretreatment by XRD. Biores Technol 151:402–405

Rahman MBA, Ishak ZI, Abdullah DK, Aziz AA, Basri M, Salleh AB (2012) Swelling and dissolution of oil palm biomass in ILss. J Oil Palm Res 24:1267–1276

Cao Y, Wu J, Zhang J, Li H, Zhang Y, He J (2009) Room temperature ILss (RTILs): a new and versatile platform for cellulose processing and derivatization. Chem Eng J 147:13–21

Zhao H, Jones CL, Baker GA, Xia S, Olubajo O, Person VN (2009) Regenerating cellulose from ILss for an accelerated enzymatic hydrolysis. J Biotechnol 139:47–54

Jurado E, Camacho F, Luzon G, Vicaria J (2006) Influence of the hollow-fibre membrane on the stability of β-galactosidase and on lactose hydrolysis: kinetic models including adsorption of the enzyme onto the membrane. Enzyme Microb Technol 39:1008–1015

Zavrel M, Bross D, Funke M, Büchs J, Spiess AC (2009) High-throughput screening for ILss dissolving (ligno-) cellulose. Biores Technol 100:2580–2587

Welton T (2004) ILss in catalysis. Coord Chem Rev 248:2459–2477

Rinaldi R, Schüth F (2009) Design of solid catalysts for the conversion of biomass. Energy Environ Sci 2:610–626

Zhang Q, Zhang S, Deng Y (2011) Recent advances in ILs catalysis. Green Chem 13:2619–2637

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ILs: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Feng L, Chen Z-L (2008) Research progress on dissolution and functional modification of cellulose in ILss. J Mol Liq 142:1–5

Shi J, Gao H, Xia Y, Li W, Wang H, Zheng C (2013) Efficient process for the direct transformation of cellulose and carbohydrates to 5-(hydroxymenthyl) furfural with dual-core sulfonic acid ILss and co-catalysts. RSC Adv 3:7782–7790

Olivier-Bourbigou H, Magna L, Morvan D (2010) ILss and catalysis: recent progress from knowledge to applications. Appl Catal A 373:1–56

Cheng J-Y, Chu Y-H (2006) 1-Butyl-2, 3-trimethyleneimidazolium bis (trifluoromethylsulfonyl) imide ([b-3C-im][NTf2]): a new, stable ILs. Tetrahedron Lett 47:1575–1579

Fukaya Y, Sugimoto A, Ohno H (2006) Superior solubility of polysaccharides in low viscosity, polar, and halogen-free 1, 3-dialkylimidazolium formates. Biomacromol 7:3295–3297

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ILss. J Am Chem Soc 124:4974–4975

Montalbo-Lomboy M, Grewell D (2015) Rapid dissolution of switchgrass in 1-butyl-3-methylimidazolium chloride by ultrasonication. Ultrason Sonochem 22:588–599

Gupta KM, Jiang J (2015) Cellulose dissolution and regeneration in ILss: a computational perspective. Chem Eng Sci 121:180–189

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ILss. Cellulose 15:59–66

Zhao H, Baker GA, Song Z, Olubajo O, Crittle T, Peters D (2008) Designing enzyme-compatible ILss that can dissolve carbohydrates. Green Chem 10:696–705

Heinze T, Schwikal K, Barthel S (2005) ILss as reaction medium in cellulose functionalization. Macromol Biosci 5:520–525

Vitz J, Erdmenger T, Haensch C, Schubert US (2009) Extended dissolution studies of cellulose in imidazolium based ILss. Green Chem 11:417–424

Kosan B, Michels C, Meister F (2007) Dissolution and forming of cellulose with ILss. Cellulose 15:59–66

Wendler F, Todi L-N, Meister F (2012) Thermostability of imidazolium ILss as direct solvents for cellulose. Thermochim Acta 528:76–84

Liu Y, Xiao W, Xia S, Ma P (2013) SO3H-functionalized acidic ILss as catalysts for the hydrolysis of cellulose. Carbohyd Polym 92:218–222

Brehm M, Radicke J, Pulst M, Shaabani F, Sebastiani D, Kressler J (2020) Dissolving cellulose in 1, 2, 3-triazolium-and imidazolium-based ILss with aromatic anions. Molecules 25:3539

Ma K, Jin X, Zheng M, Gao H (2021) Dissolution and functionalization of celluloses using 1, 2, 3-triazolium ILs. Carbohydr Polym Techno Appl 2:100109

Xu A, Zhang Y, Zhao Y, Wang J (2013) Cellulose dissolution at ambient temperature: Role of preferential solvation of cations of ILss by a cosolvent. Carbohyd Polym 92:540–544

Protz R, Lehmann A, Bohrisch J, Ganster J, Fink H-P (2021) Solubility and spinnability of cellulose-lignin blends in specific ILss. Carbohyd Polym Technol Appl 2:100041

Remsing RC, Swatloski RP, Rogers RD, Moyna G (2006) Mechanism of cellulose dissolution in the ILs 1-n-butyl-3-methylimidazolium chloride: a 13 C and 35/37 Cl NMR relaxation study on model systems. Chem Comm 12:1271–1273

Tan HT, Lee KT (2012) Understanding the impact of ILs pretreatment on biomass and enzymatic hydrolysis. Chem Eng J 183:448–458

Ohno H, Fukaya Y (2009) Task specific ILss for cellulose technology. Chem Lett 38:2–7

Guo H, Qi X, Li L, Smith RL Jr (2012) Hydrolysis of cellulose over functionalized glucose-derived carbon catalyst in ILs. Biores Technol 116:355–359

Zhu S, Wu Y, Chen Q, Yu Z, Wang C, Jin S, Ding Y, Wu G (2006) Dissolution of cellulose with ILss and its application: a mini-review. Green Chem 8:325–327

Lee SH, Doherty TV, Linhardt RJ, Dordick JS (2009) ILs-mediated selective extraction of lignin from wood leading to enhanced enzymatic cellulose hydrolysis. Biotechnol Bioeng 102:1368–1376

Xin D, Yang M, Zhang Y, Hou X, Wu J, Fan X, Wang J, Zhang J (2016) Physicochemical characterization and enzymatic digestibility of Chinese pennisetum pretreated with 1-ethyl-3-methylimidazolium acetate at moderate temperatures. Renewable Energy 91:409–416

Bian J, Peng F, Peng X-P, Xiao X, Peng P, Xu F, Sun R-C (2014) Effect of [Emim] Ac pretreatment on the structure and enzymatic hydrolysis of sugarcane bagasse cellulose. Carbohyd Polym 100:211–217

Man Z, Muhammad N, Sarwono A, Bustam MA, Vignesh Kumar M, Rafiq S (2011) Preparation of cellulose nanocrystals using an ILs. J Polym Environ 19:726–731

Mao J, Heck B, Reiter G, Laborie M-P (2015) Cellulose nanocrystals’ production in near theoretical yields by 1-butyl-3-methylimidazolium hydrogen sulfate ([Bmim] HSO4)–mediated hydrolysis. Carbohyd Polym 117:443–451

Tan XY, Abd Hamid SB, Lai CW (2015) Preparation of high crystallinity cellulose nanocrystals (CNCs) by ILs solvolysis. Biomass Bioenergy 81:584–591

Lazko J, Sénéchal T, Landercy N, Dangreau L, Raquez J-M, Dubois P (2014) Well defined thermostable cellulose nanocrystals via two-step ILs swelling-hydrolysis extraction. Cellulose 21:4195–4207

Haron GAS, Mahmood H, Noh MH, Alam MZ, Moniruzzaman M (2021) ILss as a sustainable platform for NC processing from bioresources: overview and current status. ACS Sustain Chem Eng 9:1008–1034

Schlufter K, Schmauder HP, Dorn S, Heinze T (2006) Efficient homogeneous chemical modification of bacterial cellulose in the ILs 1-N-butyl-3-methylimidazolium chloride. Macromol Rapid Commun 27:1670–1676

Hernoux-Villière A, Lévêque J-M, Kärkkäinen J, Papaiconomou N, Lajunen M, Lassi U (2014) Task-specific ILs for the depolymerisation of starch-based industrial waste into high reducing sugars. Catal Today 223:11–17

Dharaskar SA, Varma MN, Shende DZ, Yoo CK, Wasewar KL (2013) Synthesis, characterization and application of 1-butyl-3 methylimidazolium chloride as green material for extractive desulfurization of liquid fuel. Sci World J 2013:1–13

Yassin FA, El Kady FY, Ahmed HS, Mohamed LK, Shaban SA, Elfadaly AK (2015) Highly effective ILss for biodiesel production from waste vegetable oils. Egypt J Pet 24:103–111

Onkarappa H, Prakash G, Pujar G, Kumar CR, Latha M, Betageri VS (2020) Synthesis and characterization of NC using renewable resources through ILs medium. Adv Natural Sci Nanosci Nanotechnol 11:035001

Beyki MH, Bayat M, Shemirani F (2016) Fabrication of core–shell structured magnetic NC base polymeric ILs for effective biosorption of Congo red dye. Biores Technol 218:326–334

Babicka M, Woźniak M, Dwiecki K, Borysiak S, Ratajczak I (2020) Preparation of NC using ILss: 1-propyl-3-methylimidazolium chloride and 1-ethyl-3-methylimidazolium chloride. Molecules 25:1544

Onkarappa H, Prakash G, Pujar G, Kumar CR, Latha M, Betageri VS (2020) Hevea brasiliensis mediated synthesis of NC: effect of preparation methods on morphology and properties. Int J Biol Macromol 160:1021–1028

Samsudin NA, Low FW, Yusoff Y, Shakeri M, Tan XY, Lai CW, Asim N, Oon CS, Newaz KS, Tiong SK (2020) Effect of temperature on synthesis of cellulose nanoparticles via ILs hydrolysis process. J Mol Liq 308:113030

Ferreira PF, Pereira AL, Rosa MF, de Santiago-Aguiar RS (2022) Lignin-rich cellulose nanocrystals from coir fiber treated with ILss: preparation and evaluation as pickering emulsifier. Ind Crops Prod 186:115119

Reyes G, Aguayo MG, Fernández Pérez A, Pääkkönen T, Gacitúa W, Rojas OJ (2019) Dissolution and hydrolysis of bleached kraft pulp using ILss. Polymers 11:673

Morales-delaRosa S, Campos-Martin JM, Fierro JL (2018) Chemical hydrolysis of cellulose into fermentable sugars through ILss and antisolvent pretreatments using heterogeneous catalysts. Catal Today 302:87–93

Kassaye S, Pant KK, Jain S (2017) Hydrolysis of cellulosic bamboo biomass into reducing sugars via a combined alkaline solution and ILs pretreament steps. Renew Energy 104:177–184

Haafiz MM, Hassan A, Zakaria Z, Inuwa I (2014) Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohyd Polym 103:119–125

Phanthong P, Karnjanakom S, Reubroycharoen P, Hao X, Abudula A, Guan G (2017) A facile one-step way for extraction of NC with high yield by ball milling with ILs. Cellulose 24:2083–2093

Huang J, Lin C, Chen R, Xiong W, Wen X, Luo X (2020) ILs-assisted synthesis of NC adsorbent and its adsorption properties. Chin J Mater Res 34:674–682

Babicka M, Woźniak M, Szentner K, Bartkowiak M, Peplińska B, Dwiecki K, Borysiak S, Ratajczak I (2021) NC production using ILss with enzymatic pretreatment. Materials 14:3264

Jordan JH, Easson MW, Condon BD (2020) Cellulose hydrolysis using ILss and inorganic acids under dilute conditions: morphological comparison of NC. RSC Adv 10:39413–39424

Wang S, Cheng Q (2009) A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication, Part 1: Process optimization. J Appl Polym Sci 113:1270–1275

Yang C-Y, Fang TJ (2014) Combination of ultrasonic irradiation with ILs pretreatment for enzymatic hydrolysis of rice straw. Biores Technol 164:198–202

Li W, Zhao X, Liu S (2013) Preparation of entangled NC fibers from APMP and its magnetic functional property as matrix. Carbohyd Polym 94:278–285

Wu J, Feng Y, Zhang L, Wu W (2020) NC-based Surface-enhanced Raman spectroscopy sensor for highly sensitive detection of TNT. Carbohyd Polym 248:116766

Abral H, Lawrensius V, Handayani D, Sugiarti E (2018) Preparation of nano-sized particles from bacterial cellulose using ultrasonication and their characterization. Carbohyd Polym 191:161–167

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohyd Polym 83:1804–1811

Tang L, Huang B, Lu Q, Wang S, Ou W, Lin W, Chen X (2013) Ultrasonication-assisted manufacture of cellulose nanocrystals esterified with acetic acid. Biores Technol 127:100–105

Li W, Zhao X, Huang Z, Liu S (2013) NC fibrils isolated from BHKP using ultrasonication and their reinforcing properties in transparent poly (vinyl alcohol) films. J Polym Res 20:1–7

Beck S, Bouchard J, Berry R (2011) Controlling the reflection wavelength of iridescent solid films of nanocrystalline cellulose. Biomacromol 12:167–172

Acknowledgements

The authors would like to acknowledge the SATU Joint Research Scheme Grant no. ST008-2018 (Title: Development on NC Conjugated Gold Drug Delivery System for Cancer Treatment Application).

Funding

The research has been supported by SATU Joint Research Scheme Grant no. ST008-2018 (Title: Development on NC Conjugated Gold Drug Delivery System for Cancer Treatment Application).

Author information

Authors and Affiliations

Contributions

Nurul Atikah Mohd Ishak:

• Ideas; formulation or evolution of overarching research goals and aims

• Verification, whether as a part of the activity or separate, of the overall replication/reproducibility of results/experiments and other research outputs

Fatimah Zahara Abdullah

• Verification, whether as a part of the activity or separate, of the overall replication/reproducibility of results/experiments and other research outputs

Nurhidayatullaili Muhd Julkapli.

• Responsible for ensuring that the descriptions are accurate and agreed by all author

• Management and coordination responsibility for the research activity planning and execution

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Usage of ILs catalyst produced NCC with high crystallinity and surface area.

• Ultrasonication produced NCC in high yield, less agglomeration, and uniform size.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohd Ishak, N.A., Abdullah, F.Z. & Muhd Julkapli, N. Production and characteristics of nanocellulose obtained with using of ionic liquid and ultrasonication. J Nanopart Res 24, 171 (2022). https://doi.org/10.1007/s11051-022-05549-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05549-6