Abstract

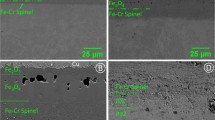

The supercritical carbon dioxide (s-CO2) Brayton cycle is currently being explored as a replacement for the steam Rankine cycle due to its potential for higher efficiency and lower cycle cost. 316 stainless steel is a candidate alloy for use in s-CO2 up to roughly 600 °C, but the mechanical effects of prolonged exposure of base and welded material in s-CO2 have not been analyzed. The potential for carburization makes this an important concern for the implementation of 316 and similar austenitic stainless steels in the s-CO2 environment. In this study, welded and base material of two types of 316–316L and 316H–were exposed in either s-CO2 or argon at 550 °C or 750 °C for 1000 h. 550 °C s-CO2 exposure yielded a thin (< 1 µm) Cr oxide with occasional nodules of duplex Fe oxide and Fe–Cr spinel that were up to 5 microns thick. However, tensile results from s-CO−2 exposure matched those of 550 °C thermal aging in Ar, indicating that no mechanically detrimental carburization occurred in either 316 variant after 1000 h exposure. Conversely, 750 °C s-CO2 exposure produced roughly 10 × the oxide thickness, with a more substantial Fe oxide (3–5 µm) on the majority of the surface and nodules of up to 40 µm thick. In comparison to aged samples, tensile testing of 750 °C CO2-exposed samples revealed ductility loss attributed to carburization. Projections of 316L performance in s-CO2 indicate that mechanically detrimental carburization—equal to that shown here for 750 °C, 1000 h—will likely be present after 7–14 years of service at 550 °C.

Similar content being viewed by others

Data Availability

The data are available upon request from AMB.

References

J. T. Mahaffey, “Effect of Partial Pressure of Oxygen and Activity of Carbon on the Corrosion of High Temperature Alloys in s-CO2 Environments,” University of Wisconsin-Madison, 2017.

T. Furukawa, Y. Inagaki, and M. Aritomi, Journal of Power and Energy Systems 4, (1), 2010 (252–261).

G. Cao, V. Firouzdor, K. Sridharan, M. Anderson, and T. R. Allen, Corrosion Science 60, 2012 (246–255).

“Boiler and Pressure Vessel Code: Section II Part D.” The American Society of Mechanical Engineers, New York, pp. 6–340, 2013.

S. Kou, Welding Metallurgy, (Wiley, New York, 2003).

S. L. Mannan, S. C. Chetal, B. Raj, and S. B. Bhoje, Transactions of the Institute of Metal Finishing 56, (2), 2003 (155–178).

H. Lee, Nuclear Engineering and Design 308, 2016 (142–153).

P. Kumar and A. Pai, Procedia Engineering 86, 2014 (173–183).

A. Fissolo, B. Marini, G. Nais, and P. Wident, Journal of Nuclear Materials 233, 1996 (156–161).

G. Zheng, B. Kelleher, G. Cao, M. Anderson, T. Allen, and K. Sridharan, Journal of Nuclear Materials 461, 2015 (143–150).

V. Dostal, “A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors,” Massachusetts Institute of Technology, 2004.

Y. Kato, T. Nitawaki, and Y. Muto, Nuclear Engineering and Design 230, (1–3), 2004 (195–207).

I. G. Wright, B. A. Pint, J. P. Shingledecker, and D. Thimsen, “Materials Considerations for Supercritical CO2 Turbine Cycles,” in ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, 2013.

D. Young, P. Huczkowski, T. Olszewski, T. Hüttel, L. Singheiser, and W. J. Quadakkers, Corrosion Science 88, 2014 (161–169).

F. Rouillard, G. Moine, M. Tabarant, and J. C. Ruiz, “Corrosion of 9Cr Steel in CO2 at Intermediate Temperature II: Mechanism of Carburization,” Oxid. Met., pp. 57–70, 2012.

K. Arioka, T. Yamada, T. Terachi, and G. Chiba, Corrosion Science 62, (7), 2006 (568–575).

V. Magula, J. Liao, K. Ikeuchi, T. Kuroda, Y. Kikuchi, and F. Matsuda, Transactions of JWRI 25, (1), 1996 (49–58).

H. Shaikh, H. S. Khatak, S. K. Seshadri, J. B. Gnanamoorthy, and P. Rodriguez, “Effect of ferrite transformation on the tensile and stress corrosion properties of type 316 L stainless steel weld metal thermally aged at 873K,” vol. 26, no. 7, pp. 1859–1868, 1995.

B. Weiss and R. Stickler, Metallurgical and Materials Transactions 3, (April), 1972 (851–866).

T. P. S. Gill, M. Vijayalakshmi, J. B. Gnanamoorthy, and K. A. Padmanabhan, Welding Journal 65, (5), 1986 (122–128).

C. Hsieh and W. Wu, ISRN Metall. 2012, (4), 2012 (1–16).

D. M. E. Villanueva, F. C. P. Junior, R. L. Plaut, and A. F. Padilha, Materials Science and Technology 22, (9), 2006 (1098–1104).

A. S. Lima, A. M. Nascimento, H. F. G. Abreu, and P. de Lima-Neto, Journal of Materials Science 40, (1), 2005 (139–144).

J. W. Simmons, D. G. Atteridge, and S. M. Bruemmer, Corrosion 48, (12), 1992 (976–982).

J. D. Tucker et al., “Supercritical CO2 round robin test program,” in The 6th International Supercritical CO2 Power Cycles Symposium, 2018.

J. D. Tucker, “Advancement of supercritical carbon dioxide technology through round robin testing and fundamental modeling,” 2019.

F. Rouillard and T. Furukawa, Corrosion Science 105, (April), 2016 (120–132).

M. Sun, X. Wu, Z. Zhang, and E. Han, Corrosion Science 51, (5), 2009 (1069–1072).

K. I. Choudhry, S. Mahboubi, G. A. Botton, J. R. Kish, and I. M. Svishchev, Corrosion Science 100, 2015 (222–230).

Y. Cui and C. D. Lundin, Materials & Design 28, (1), 2007 (324–328).

T. W. Nelson, J. C. Lippold, W. Lin, and W. A. Baeslack III., Welding Reasearch Supplement 76, (3), 1997 (110–119).

M. J. Cieslak, A. M. Ritter, and W. F. Savage, Welding Journal 61, (January), 1982 (1–8).

R. M. Molak, K. Paradowski, T. Brynk, L. Ciupinski, Z. Pakiela, and K. J. Kurzydlowski, International Journal of Pressure Vessels and Piping 86, (1), 2009 (43–47).

ASTM E8/E8M-16a Standard Test Methods for Tension Testing of Metallic Materials. West Conshohocken, PA: ASTM International, 2016.

J. Mahaffey, D. Adam, A. Brittan, M. Anderson, and K. Sridharan, Oxidation of Metals 86, (5–6), 2016 (567–580).

J. Mahaffey, A. Schroeder, D. Adam, A. Brittan, M. Anderson, A. Couet, and K. Sridharan, Metallurgical and Materials Transactions A 49, 2018 (1–12).

J. Mahaffey et al., “Effect of Oxygen Impurity on Corrosion in Supercritical CO2 Environments,” in The 5th International Supercritical CO2 Power Cycles Symposium, 2016.

ASTM E92–17 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. West Conshohocken, PA: ASTM International, 2017.

T. D. Nguyen, J. Zhang, and D. J. Young, Corrosion Science 112, 2016 (110–127).

F. Rouillard, G. Moine, L. Martinelli, and J. C. Ruiz, Oxidation of Metals 77, (1–2), 2012 (27–55).

S. Adachi and N. Ueda, Advanced Powder Technology 24, (5), 2013 (818–823).

S. Kalainathan, S. Sathyajith, and S. Swaroop, Optics and Lasers in Engineering 50, (12), 2012 (1740–1745).

A. M. Brittan, “The Study of Mechanical Properties of Welded and Base Material after Exposure to Supercritical CO2,” University of Wisconsin-Madison, 2018.

A. M. Brittan, J. T. Mahaffey, N. E. Colgan, M. Elbakhshwan, and M. H. Anderson, Corrosion Science 169, 2020 (108639).

J. K. L. Lai, Materials Science and Engineering 61, (2), 1983 (101–109).

“Boiler and Pressure Vessel Code: Section III Division 5.” The American Society of Mechanical Engineers, New York, 2019.

Acknowledgements

The author gratefully acknowledges the contributions to the work made by Paul Brooks of the University of Wisconsin-Madison. Additionally, a special thanks to Ryan Carroll and Peter Li who performed significant work in completing this research. The author also acknowledges the assistance of Dr. Julie Tucker at Oregon State University for aiding the writing process of this research. Sandia National Laboratories is a multimission laboratory managed and operated by National Technology & Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525. This paper describes objective technical results and analysis. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the U.S. Department of Energy or the United States Government.

Funding

This work was supported by Advance supercritical carbon dioxide cycles DE-EE0007120 and the U.S. Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Brittan, A., Mahaffey, J., Adam, D. et al. Mechanical and Corrosion Response of 316SS in Supercritical CO2. Oxid Met 95, 409–425 (2021). https://doi.org/10.1007/s11085-021-10026-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10026-x