Abstract

Purpose

Solid dispersions (SDs) represent the most common formulation technique used to increase the dissolution rate of a drug. In this work, the three most common methods used to prepare SDs, namely spray-drying, solvent-casting and freeze-drying, have been compared in order to investigate their effect on increasing drug dissolution rate.

Methods

Three formulation strategies were used to prepare a polymer mixture of polyvinyl-alcohol (PVA) and maltodextrin (MDX) as SDs loaded with the following three model drugs, all of which possess a poor solubility: Olanzapine, Dexamethasone, and Triamcinolone acetonide. The SDs obtained were analysed and compared in terms of drug particle size, drug-loading capacity, surface homogeneity, and dissolution profile enhancement. Physical-chemical characterisation was conducted on pure drugs, as well as the formulations made, by way of thermal analysis and infrared spectroscopy.

Result

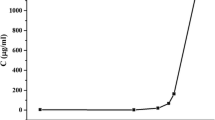

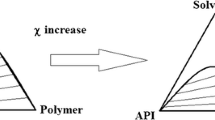

The polymers used were able to increase drug saturation solubility. The formulation strategies affected the drug particle size, with the solvent-casting method resulting in more homogenous particle size and distribution when compared to the other methods. The greatest enhancement in the drug dissolution rate was seen for all the samples prepared using the solvent-casting method.

Conclusion

All of the methods used were able to increase the dissolution rate of the pure drugs alone, however, the solvent-casting method produced SDs with a higher surface homogeneity, drug incorporation capability, and faster dissolution profile than the other techniques.

Similar content being viewed by others

Abbreviations

- Δcp:

-

Heat capacity

- APIs:

-

Active pharmaceutical ingredients

- BCS:

-

Biopharmaceutical classification systems

- DMSO:

-

Dimethyl sulfoxide

- DSC:

-

Differential scanning calorimetry

- Dsm:

-

Dexamethasone

- DPBS:

-

Dulbecco buffer phosphate

- FTIR:

-

Fourier transform infrared

- HME:

-

Hot melt extrusion

- HPMC:

-

Hydroxypropyl-methylcellulose

- KBr:

-

Potassium bromide

- MDX:

-

Maltodextrin

- Olz:

-

Olanzapine

- PVA:

-

Polyvinyl-alcohol

- SD:

-

Solid dispersion

- SEM:

-

Scanning electron microscopy analysis

- Tg:

-

Glass transition

- TGA:

-

Thermogravimetric analysis

- Tm:

-

Melting point

- Trm:

-

Triamcinolone acetonide

- UV:

-

Ultraviolet

References

Kalepu S, Nekkanti V. Insoluble drug delivery strategies: review of recent advances and business prospects. Acta Pharm Sin B. 2015;5(5):442–53. https://doi.org/10.1016/j.apsb.2015.07.003.

Samie A, Desiraju GR, Banik M. Salts and cocrystals of the antidiabetic drugs gliclazide, tolbutamide, and glipizide: solubility enhancements through drug–coformer interactions. Cryst Growth Des. 2017;17(5):2406–17. https://doi.org/10.1021/acs.cgd.6b01804.

Campardelli R, Oleandro E, Scognamiglio M, Della Porta G, Reverchon E. Palmitoylethanolamide sub-micronization using fast precipitation followed by supercritical fluids extraction. Powder Technol. 2017;305:217–25. https://doi.org/10.1016/j.powtec.2016.09.084.

Marano S, Barker SA, Raimi-Abraham BT, Missaghi S, Rajabi-Siahboomi A, Aliev AE, et al. Microfibrous solid dispersions of poorly water-soluble drugs produced via centrifugal spinning: unexpected dissolution behavior on recrystallization. Mol Pharm. 2017;14(5):1666–80. https://doi.org/10.1021/acs.molpharmaceut.6b01126.

Marano S, Barker SA, Raimi-Abraham BT, Missaghi S, Rajabi-Siahboomi A, Craig DQM. Development of micro-fibrous solid dispersions of poorly water-soluble drugs in sucrose using temperature-controlled centrifugal spinning. Eur J Pharm Biopharm. 2016;103:84–94. https://doi.org/10.1016/j.ejpb.2016.03.021.

Pina MF, Zhao M, Pinto JF, Sousa JJ, Craig DQM. The influence of drug physical state on the dissolution enhancement of solid dispersions prepared via hot-melt extrusion: a case study using olanzapine. J Pharm Sci. 2014;103(4):1214–23. https://doi.org/10.1002/jps.23894.

Mogal SA, Gurjar PN, Yamgar DS, Kamod AC. Solid dispersion technique for improving solubility of some poorly soluble drugs. Der Pharm Lett. 2012;4(5):1574–86.

Michael E. Aulton pharmaceutics : the design and manufacture of medicines. 2007.

Goldberg AH, Gibaldi M, Kanig JL, Mayersohn M. Increasing dissolution rates and gastrointestinal absorption of drugs via solid solutions and eutectic mixtures. IV. Chloramphenicol--urea system. J Pharm Sci. 1966;55(6):581–3. https://doi.org/10.1002/jps.2600540810.

S. Friedlander DS. Handbook of mathematical. Fluid Dynamics. 2007.

Lu T, Sun Y, Ding D, Zhang Q, Fan R, He Z, et al. Study on enhanced dissolution of Azilsartan-loaded solid dispersion, prepared by combining wet milling and spray-drying technologies. AAPS PharmSciTech. 2017;18(2):473–80. https://doi.org/10.1208/s12249-016-0531-1.

Douglas Collins. The story of Kodak. 1990.

Wolff IA, Davis HA, Cluskey JE, Gundrum LJ, Rist CE. Preparation of films from amylose. Ind Eng Chem. 1951;43(4):915–9. https://doi.org/10.1021/ie50496a039.

Saldanha JM, Kyu T. Influence of solvent casting on the evolution of phase morphology of PC/PMMA blends. Macromolecules. 1987;20(11):2840–7. https://doi.org/10.1021/ma00177a033.

Lee Y, Moon HT, Byun Y. Preparation of slightly hydrophobic heparin derivatives which can be used for solvent casting in polymeric formulation. Thromb Res. 1998;92(4):149–56. https://doi.org/10.1016/S0049-3848(98)00124-8.

Wlodarski K, Sawicki W, Haber K, et al. Physicochemical properties of tadalafil solid dispersions - impact of polymer on the apparent solubility and dissolution rate of tadalafil. Eur J Pharm Biopharm. 2015;94(May):106–15. https://doi.org/10.1016/j.ejpb.2015.04.031.

Takeuchi I, Taniguchi Y, Tamura Y, Ochiai K, Makino K. Effects of l -leucine on PLGA microparticles for pulmonary administration prepared using spray drying: fine particle fraction and phagocytotic ratio of alveolar macrophages. Colloids Surfaces A Physicochem Eng Asp. 2018;537(October 2017):411–7. https://doi.org/10.1016/j.colsurfa.2017.10.047.

Ogawa N, Hiramatsu T, Suzuki R, et al. Improvement in the water solubility of drugs with a solid dispersion system by spray drying and hot-melt extrusion with using the amphiphilic polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer and D-mannitol. Eur J Pharm Sci. 2018;111(June 2017):205–14. https://doi.org/10.1016/j.ejps.2017.09.014.

Beak I-H, Kim M-S. Improved supersaturation and oral absorption of dutasteride by amorphous solid dispersions. Chem Pharm Bull. 2012;60(11):1468–73. https://doi.org/10.1248/cpb.c12-00563.

Mahmah O, Tabbakh R, Kelly A, Paradkar A. A comparative study of the effect of spray drying and hot-melt extrusion on the properties of amorphous solid dispersions containing felodipine. J Pharm Pharmacol. 2014;66(2):275–84. https://doi.org/10.1111/jphp.12099.

Modica De Mohac L, Caruana R, Pavia FC, Cavallaro G, Giammona G, Licciardi M. Multicomponent solid dispersion as a formulation strategy to improve drug permeation: A case study on the anti-colorectal cancer irinotecan. J Drug Deliv Sci Technol. 2019;52:346–354. https://doi.org/10.1016/j.jddst.2019.04.040.

Nireesha GR, Divya L, Sowmya C, Venkateshan N, Babu MN, Lavakumar V. Lyophilization / Freeze Drying. 2013;3(4):87–98.

Shivanand A, Mukhopadhayaya S. A review on lyophilization : a technique to improve stability of hygroscopic , Thermolabile Substances. 2017;5(11).

Emami F, Vatanara A, Park EJ, Na DH. Drying technologies for the stability and bioavailability of biopharmaceuticals. Pharmaceutics. 2018;10(3):1–22. https://doi.org/10.3390/pharmaceutics10030131.

Zhong H, Chan G, Hu Y, Hu H, Ouyang D. A comprehensive map of FDA-approved pharmaceutical products. Pharmaceutics. 2018;10(4):263. https://doi.org/10.3390/pharmaceutics10040263.

Naik JB, Mokale VJ. Preparation of freeze-dried solid dispersion powder using mannitol to enhance solubility of lovastatin and development of sustained release tablet dosage form 2014;1(1):11–26.

van Drooge D-J, Hinrichs WLJ, Dickhoff BHJ, et al. Spray freeze drying to produce a stable Δ9-tetrahydrocannabinol containing inulin-based solid dispersion powder suitable for inhalation. Eur J Pharm Sci. 2005;26(2):231–40. https://doi.org/10.1016/j.ejps.2005.06.007.

Allen LV, Nicholas G, Ansel HC. Ansel’s pharmaceutical dosage forms. Anticancer Res. 2013;33(5):2345 http://www.ncbi.nlm.nih.gov/pubmed/23645785.

Fuentes A, Pineda M, Venkata K. Comprehension of top 200 prescribed drugs in the US as a resource for pharmacy teaching, training and practice pharmacy 2018;6(2):43. https://doi.org/10.3390/pharmacy6020043.

Clinical N. The top 300 of 2019 provided by the clincalc drugstats database. https://clincalc.com/DrugStats/Top300Drugs.aspx. Published 2019.

European Pharmacopeia 7.6. 20903E_Dissolution test for solid dosage forms. Eur Pharmacopoeia. 2012;(1):3–9.

Drug.com. Dexamethasone 20 mg tablets. https://www.drugs.com/uk/dexamethasone-20-mg-tablets-leaflet.html.

Intrapharma. Triamcinolone Hexacetonide 20 Mg / Ml Suspension for Injection.; 2017. https://www.medicines.org.uk/emc/files/pil.5408.pdf.

Aurobindo Pharma - Milpharm Ltd. Olanzapine 20 mg tablets. https://www.medicines.org.uk/emc/product/3095/smpc. Published 2019.

Raimi-Abraham BT, Mahalingam S, Davies PJ, Edirisinghe M, Craig DQM. Development and characterization of amorphous nanofiber drug dispersions prepared using pressurized gyration. Mol Pharm. 2015:acs.molpharmaceut.5b00127. https://doi.org/10.1021/acs.molpharmaceut.5b00127.

Rodrigues LB, Leite HF, Yoshida MI, Saliba JB, Junior ASC, Faraco AAG. In vitro release and characterization of chitosan films as dexamethasone carrier. Int J Pharm. 2009;368(1–2):1–6. https://doi.org/10.1016/j.ijpharm.2008.09.047.

Hiriyanna SH, Basavaiah K, Goud P, Dhayanithi V, Raju K, Pati HP. Identification and characterization of olanzapine degradation products under oxidative stress conditions. Acta Chromatogr. 2008;20(1):81–93. https://doi.org/10.1556/AChrom.20.2008.1.7.

Shin S-C, Kim J-Y, Oh I-J. Mucoadhesive and physicochemical characterization of Carbopol-Poloxamer gels containing triamcinolone Acetonide. Drug Dev Ind Pharm. 2000;26(3):307–12. https://doi.org/10.1081/DDC-100100358.

Modica de Mohac L, Keating A, de Fátima Pina M, Raimi-Abraham B. Engineering of nanofibrous amorphous and crystalline solid dispersions for oral drug delivery. Pharmaceutics. 2018;11(1):7. https://doi.org/10.3390/pharmaceutics11010007.

Meng F, Gala U, Chauhan H. Classification of solid dispersions: correlation to (i) stability and solubility (ii) preparation and characterization techniques. Drug Dev Ind Pharm. 2015;41(9):1401–15. https://doi.org/10.3109/03639045.2015.1018274.

Hallouard F, Mehenni L, Lahiani-Skiba M, Anouar Y, Skiba M. Solid dispersions for Oral administration: an overview of the methods for their preparation. Curr Pharm Des. 2016;22(32):4942–58. https://doi.org/10.2174/1381612822666160726095916.

Agama-Acevedo E, Bello-Perez LA. Starch as an emulsions stability: the case of octenyl succinic anhydride (OSA) starch. Curr Opin Food Sci. 2017;13:78–83. https://doi.org/10.1016/j.cofs.2017.02.014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

De Mohac, L.M., Caruana, R., Cavallaro, G. et al. Spray-Drying, Solvent-Casting and Freeze-Drying Techniques: a Comparative Study on their Suitability for the Enhancement of Drug Dissolution Rates. Pharm Res 37, 57 (2020). https://doi.org/10.1007/s11095-020-2778-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11095-020-2778-1