Abstract

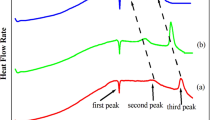

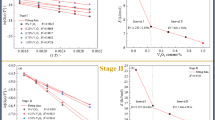

In this research, non-isothermal kinetic analysis of the oxidation process of Al–50Mg (wt%) powder mixture was performed by employing differential scanning calorimetry and thermogravimetry analysis techniques. The research findings revealed that oxidation of this powder mixture was completed at lower temperatures compared to that of pure aluminum powder; and furthermore, it enjoyed a higher thermal efficiency than that of pure magnesium powder. Oxidation of this mixture powder led to the formation of magnesium oxide (MgO) and spinel phase (MgAl2O4) during the first and second oxidation steps, respectively. Moreover, to calculate the activation energy (E) over a wide range of degree of conversion (α), two isoconversional methods, including Starink and Friedman methods were used. Activation energies decreased as the reaction progressed at both stages, indicating that these stages were multi-step reactions. Furthermore, the invariant kinetic parameter method and fitting model were used to determine the empirical kinetic triplets (i.e. E, pre-exponential factor (A) and reaction model (g(α))). The obtained results showed that the first stage was controlled by the second order Avrami-Erofeev mechanism (A2), two-dimensional phase boundary reaction (R2), and two-dimensional diffusion (D2) models at heating rates of 5, 10, and 30 °C/min. The second stage was controlled by the third order Avrami-Erofeev mechanism (A3) and A2 at heating rates of 5 and 10 °C/min, while for a heating rate of 30 °C/min, the mechanism of reaction changes from A3 to A2.

Similar content being viewed by others

References

Wen D (2010) Nanofuel as a potential secondary energy carrier. Energy Environ Sci 3:591. https://doi.org/10.1039/b906384f

Tanvir S, Qiao L (2015) Effect of addition of energetic nanoparticles on droplet-burning rate of liquid fuels. J Propuls Power 31:408–415. https://doi.org/10.2514/1.B35500

Velasco F, Guzmán S, Moral C, Bautista A (2013) Oxidation of micro-sized aluminium particles: hollow alumina spheres. Oxid Met 80:403–422. https://doi.org/10.1007/s11085-013-9408-9

Goroshin S, Higgins A, Kamel M (2001) Powdered metals as fuel for hypersonic ramjets. 37th Jt Propuls Conf Exhib 1:AIAA-2001–3919. ****https://doi.org/10.2514/6.2001-3919

Moser G, Tschamber V, Schönnenbeck C et al (2019) Non-isothermal oxidation and kinetic analysis of pure magnesium powder. J Therm Anal Calorim 136:2145–2155. https://doi.org/10.1007/s10973-018-7845-z

Trunov M, Schoenitz M, Dreizin E (2005) Ignition of aluminum powders under different experimental conditions. Propellants Explos Pyrotech 30:36–43. https://doi.org/10.1002/prep.200400083

Nie H, Schoenitz M, Dreizin EL (2016) Initial stages of oxidation of aluminum powder in oxygen. J Therm Anal Calorim 125:129–141. https://doi.org/10.1007/s10973-016-5369-y

Schoenitz M, Patel B, Agboh O, Dreizin EL (2010) Oxidation of aluminum powders at high heating rates. Thermochim Acta 507–508:115–122. https://doi.org/10.1016/j.tca.2010.05.010

Rouillard F, Cabet C, Wolski K, Pijolat M (2009) Oxidation of a chromia-forming nickel base alloy at high temperature in mixed diluted CO/H2O atmospheres. Corros Sci 51:752–760. https://doi.org/10.1016/j.corsci.2009.01.019

Zhu X, Schoenitz M, Dreizin EL (2009) Aluminum powder oxidation in CO2 and mixed CO2/O2 environments. J Phys Chem C 113:6768–6773. https://doi.org/10.1021/jp809816u

Chunmiao Y, Lifu Y, Chang L et al (2013) Thermal analysis of magnesium reactions with nitrogen/oxygen gas mixtures. J Hazard Mater 260:707–714. https://doi.org/10.1016/j.jhazmat.2013.06.047

Rufino B, Boulch F, Coulet M-V et al (2007) Influence of particles size on thermal properties of aluminium powder. Acta Mater 55:2815–2827. https://doi.org/10.1016/j.actamat.2006.12.017

Hasani S, Panjepour M, Shamanian M (2014) Non-isothermal kinetic analysis of oxidation of pure aluminum powder particles. Oxid Met 81:299–313. https://doi.org/10.1007/s11085-013-9413-z

Hasani S, Panjepour M, Shamanian M (2012) The oxidation mechanism of pure aluminum powder particles. Oxid Met 78:179–195. https://doi.org/10.1007/s11085-012-9299-1

Hasani S, Soleymani AP, Panjepour M, Ghaei A (2014) A tension analysis during oxidation of pure aluminum powder particles: non-isothermal condition. Oxid Met 82:209–224. https://doi.org/10.1007/s11085-014-9488-1

Trunov MA, Schoenitz M, Zhu X, Dreizin EL (2005) Effect of polymorphic phase transformations in Al2O3 film on oxidation kinetics of aluminum powders. Combust Flame 140:310–318. https://doi.org/10.1016/j.combustflame.2004.10.010

Li L, Zou H, Cai S (2016) Thermal behaviour of gas atomised Al–20Mg–2Zr alloy powder. Mater Sci Technol 32:863–870. https://doi.org/10.1179/1743284715Y.0000000096

Legrand B, Marion M, Chauveau C et al (2001) Ignition and combustion of levitated magnesium and aluminum particles in carbon dioxide. Combust Sci Technol 165:151–174. https://doi.org/10.1080/00102200108935830

Zou H, Li L, Cai S (2016) Effect of magnesium-rich phase on oxidation properties of atomized aluminum–magnesium powders. J Propuls Power 32:32–37. https://doi.org/10.2514/1.B35781

Karimpour M, Eatezadi SR, Hasani S, Ghaei A (2019) The oxidation mechanism of pure magnesium powder particles: a mathematical approach. Metall Mater Trans B 50:1597–1607. https://doi.org/10.1007/s11663-019-01588-y

Aly Y, Hoffman VK, Schoenitz M, Dreizin EL (2014) Reactive, mechanically alloyed Al·Mg powders with customized particle sizes and compositions. J Propuls Power 30:96–104. https://doi.org/10.2514/1.B35031

Lomba R, Bernard S, Gillard P et al (2016) Comparison of combustion characteristics of magnesium and aluminum powders. Combust Sci Technol 188:1857–1877. https://doi.org/10.1080/00102202.2016.1211871

Kim K (2015) Formation of endogenous MgO and MgAl2O4 particles and their possibility of acting as substrate for heterogeneous nucleation of aluminum grains. Surf Interface Anal 47:429–438. https://doi.org/10.1002/sia.5726

Nie H, Schoenitz M, Dreizin EL (2016) Oxidation of magnesium: implication for aging and ignition. J Phys Chem C 120:974–983. https://doi.org/10.1021/acs.jpcc.5b08848

Shoshin YL, Mudryy RS, Dreizin EL (2002) Preparation and characterization of energetic Al-Mg mechanical alloy powders. Combust Flame 128:259–269. https://doi.org/10.1016/S0010-2180(01)00351-0

Xu C, Zou H, Cai S (2015) Thermal reactivity of Al–Mg–Li alloy powders. J Mater Res 30:2238–2246. https://doi.org/10.1557/jmr.2015.179

Corcoran AL, Wang S, Aly Y, Dreizin EL (2015) Combustion of mechanically alloyed Al∙Mg powders in products of a hydrocarbon flame. Combust Sci Technol 187:807–825. https://doi.org/10.1080/00102202.2014.973951

Schoenitz M, Dreizin EL (2003) Structure and properties of Al–Mg mechanical alloys. J Mater Res 18:1827–1836. https://doi.org/10.1557/JMR.2003.0255

Matli P, Shakoor R, Amer Mohamed A, Gupta M (2016) Microwave rapid sintering of Al-metal matrix composites: a review on the effect of reinforcements. Microstruct Mech Prop Metals (Basel) 6:143. https://doi.org/10.3390/met6070143

Batool SA, Wadood A, Rehman MAU (2019) Comparison of aluminum based alloys reinforced with intermetallic developed by powder metallurgy and arc melting routes. Soldag Inspeção. https://doi.org/10.1590/0104-9224/si24.19

Faisal H, Darminto T, Zainuri M (2016) Interfacial reactions and wetting in Al-Mg sintered by powder metallurgy process. AIP Conf Proc 1725:020017. https://doi.org/10.1063/1.4945471

Yuan X, Qu X, Yin H et al (2019) Effects of compaction velocity on the sinterability of Al-Fe-Cr-Ti PM alloy. Materials (Basel) 12:3005. https://doi.org/10.3390/ma12183005

Starink M (2003) The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta 404:163–176. https://doi.org/10.1016/S0040-6031(03)00144-8

Starink MJ (2007) Activation energy determination for linear heating experiments: deviations due to neglecting the low temperature end of the temperature integral. J Mater Sci 42:483–489. https://doi.org/10.1007/s10853-006-1067-7

Friedman HL (2007) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp 6:183–195. https://doi.org/10.1002/polc.5070060121

Budrugeac P, Segal E, Pérez-Maqueda LA, Criado JM (2004) The use of the IKP method for evaluating the kinetic parameters and the conversion function of the thermal dehydrochlorination of PVC from non-isothermal data. Polym Degrad Stab 84:311–320. https://doi.org/10.1016/j.polymdegradstab.2004.01.017

Jaafari Z, Seifoddini A, Hasani S, Rezaei-Shahreza P (2018) Kinetic analysis of crystallization process in [(Fe0.9Ni0.1)77Mo5P9C7.5B1.5]100−xCux (x = 0.1 at.%) BMG. J Therm Anal Calorim 134:1565–1574. https://doi.org/10.1007/s10973-018-7372-y

Vyazovkin S, Burnham AK, Criado JM et al (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Khawam A, Flanagan DR (2006) Basics and applications of solid-state kinetics: a pharmaceutical perspective. J Pharm Sci 95:472–498. https://doi.org/10.1002/jps.20559

Hasani S, Shamanian M, Shafyei A et al (2014) Non-isothermal kinetic analysis on the phase transformations of Fe–Co–V alloy. Thermochim Acta 596:89–97. https://doi.org/10.1016/j.tca.2014.09.020

Rezaei-Shahreza P, Seifoddini A, Hasani S (2017) Non-isothermal kinetic analysis of nano-crystallization process in (Fe41Co7Cr15Mo14Y2C15)94B6 amorphous alloy. Thermochim Acta 652:119–125. https://doi.org/10.1016/j.tca.2017.03.017

Marinović-Cincović M, Janković B, Jovanović V et al (2013) The kinetic and thermodynamic analyses of non-isothermal degradation process of acrylonitrile–butadiene and ethylene–propylene–diene rubbers. Compos Part B Eng 45:321–332. https://doi.org/10.1016/j.compositesb.2012.08.006

Burnham AK, Dinh LN (2007) A comparison of isoconversional and model-fitting approaches to kinetic parameter estimation and application predictions. J Therm Anal Calorim 89:479–490. https://doi.org/10.1007/s10973-006-8486-1

Vyazovkin S, Wight CA (1999) Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta 340–341:53–68. https://doi.org/10.1016/S0040-6031(99)00253-1

Uzun N, Çolak AT, Emen FM, Çılgı GK (2016) The thermal and detailed kinetic analysis of dipicolinate complexes. J Therm Anal Calorim 124:1735–1744. https://doi.org/10.1007/s10973-016-5251-y

Ledeti A, Olariu T, Caunii A et al (2018) Evaluation of thermal stability and kinetic of degradation for levodopa in non-isothermal conditions. J Therm Anal Calorim 131:1881–1888. https://doi.org/10.1007/s10973-017-6671-z

Campostrini R, Abdellatief M, Leoni M, Scardi P (2014) Activation energy in the thermal decomposition of MgH2 powders by coupled TG–MS measurements. J Therm Anal Calorim 116:225–240. https://doi.org/10.1007/s10973-013-3539-8

Singh A, Sharma TC, Kishore P (2017) Thermal degradation kinetics and reaction models of 1,3,5-triamino-2,4,6-trinitrobenzene-based plastic-bonded explosives containing fluoropolymer matrices. J Therm Anal Calorim 129:1403–1414. https://doi.org/10.1007/s10973-017-6335-z

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201:68–69. https://doi.org/10.1038/201068a0

Gorbachev VM (1975) A solution of the exponential integral in the non-isothermal kinetics for linear heating. J Therm Anal 8:349–350. https://doi.org/10.1007/BF01904012

Gallet J-J, Silly MG, El KM et al (2017) Chemical and kinetic insights into the thermal decomposition of an oxide layer on Si(111) from millisecond photoelectron spectroscopy. Sci Rep 7:14257. https://doi.org/10.1038/s41598-017-14532-4

Al Soubaihi R, Saoud K, Dutta J (2018) Critical review of low-temperature CO oxidation and hysteresis phenomenon on heterogeneous catalysts. Catalysts 8:660. https://doi.org/10.3390/catal8120660

Kasap S, Málek J, Svoboda R (2017) Thermal properties and thermal analysis: fundamentals, experimental techniques and applications. Springer Handbook of Electronic and Photonic Materials. Springer International Publishing, Cham, pp 1–1

Hasani S, Panjepour M, Shamanian M (2012) Effect of atmosphere and heating rate on mechanism of MoSi2 formation during self-propagating high-temperature synthesis. J Therm Anal Calorim. https://doi.org/10.1007/s10973-011-1747-7

Sanchez ME, Otero M, Gómez X, Morán A (2009) Thermogravimetric kinetic analysis of the combustion of biowastes. Renew Energy 34:1622–1627. https://doi.org/10.1016/j.renene.2008.11.011

Vyazovkin S, Chrissafis K, Di Lorenzo ML et al (2014) ICTAC kinetics committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta 590:1–23. https://doi.org/10.1016/j.tca.2014.05.036

Hasani S, Panjepour M, Shamanian M (2010) A study of the effect of aluminum on MoSi2 formation by self-propagation high-temperature synthesis. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2010.04.159

Xu C, Gao W (2000) Pilling-Bedworth ratio for oxidation of alloys. Mater Res Innov 3:231–235. https://doi.org/10.1007/s100190050008

Tan Q, Atrens A, Mo N, Zhang M-X (2016) Oxidation of magnesium alloys at elevated temperatures in air: a review. Corros Sci 112:734–759. https://doi.org/10.1016/j.corsci.2016.06.018

Khawam A, Flanagan DR (2006) Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B 110:17315–17328. https://doi.org/10.1021/jp062746a

Erceg M, Kovačić T, Perinović S (2008) Kinetic analysis of the non-isothermal degradation of poly(3-hydroxybutyrate) nanocomposites. Thermochim Acta 476:44–50. https://doi.org/10.1016/j.tca.2008.07.009

Vrandečić NS, Erceg M, Jakić M, Klarić I (2010) Kinetic analysis of thermal degradation of poly(ethylene glycol) and poly(ethylene oxide)s of different molecular weight. Thermochim Acta 498:71–80. https://doi.org/10.1016/j.tca.2009.10.005

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Soltani, M., Seifoddini, A., Hasani, S. et al. Non-isothermal kinetic analysis of the oxidation of Al–50Mg powder mixture. Reac Kinet Mech Cat 131, 367–381 (2020). https://doi.org/10.1007/s11144-020-01845-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01845-1