Abstract

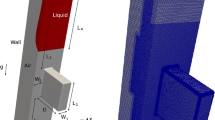

We present an analysis for the process of fluid infiltration into a deformable, thin and permeable web that moves in close proximity over a rigid and stationary solid cylinder. While this is a process of significant interest in a range of coating, printing and composites pultrusion processes, its hydrodynamics have received limited attention in the open literature. The flow in the film separating the web from the cylinder is described by lubrication theory, while fluid transfer into the web is governed by Darcy’s law. The deformation of the web at each position is a linear function of the local gap pressure; this is consistent with the assumption of a thin and rigidly supported web. Our results indicate that the web/fluid interface is forced away from the cylinder surface as it approaches it and bounces back downstream from the minimum separation point. This behavior produces a non-symmetric gap between the adjacent surfaces, and this is shown to have critical influence on the final amount of penetrating fluid. The extent of fluid penetration is also found to be affected by the web elasticity (expressed by the dimensionless Ne number) and permeability (expressed in dimensionless form via \(\hat{{K}})\) where under a specific Ne and \(\hat{{K}}\) combination a maximum penetration depth is obtained. Finally, we derive a closed-form asymptotic solution for the final infiltration depth in the limit of Ne \(<<\) 1 and \(\hat{{K}}<<\)1 and test its predictions against the above-mentioned numerical results.

Similar content being viewed by others

References

Andersson, H.M., Lundström, T.S., Gebart, B.R.: Numerical model for vacuum infusion manufacturing of polymer composites. Int. J. Numer. Method. Heat. 13, 383–394 (2003)

Ascanio, G., Carreau, P.J., Brito-de la Fuente, E., Tanguy, P.A.: Forward deformable roll coating at high speed with Newtonian fluids. Chem. Eng. Res. Des. 82, 390–397 (2004)

Ascanio, G., Ruiz, G.: Measurement of pressure distribution in a deformable nip of counter-rotating rolls. Meas. Sci. Technol. 17, 2430–2436 (2006)

Barry, S., Aldis, G., Mercer, G.: Injection of fluid into a layer of deformable porous medium. Appl. Mech. Rev. 48, 722–726 (1995)

Bates, P.J., Kendall, J., Taylor, D., Cunningham, M.: Pressure build-up during melt impregnation. Compos. Sci. Technol. 62, 379–384 (2002)

Bates, P.J., Zou, X.P.: Polymer melt impregnation of glass roving. Int. Polym. Proc. 27, 376–386 (2002)

Bear, J.: Dynamics of Fluids in Porous Media. Courier Dover Publications, New York (1988)

Benkreira, H., Edwards, M.F., Wilkinson, W.L.: A semi-empirical model of the forward roll coating flow of Newtonian fluids. Chem. Eng. Sci. 36, 423–427 (1981)

Benkreira, H., Edwards, M.F., Wilkinson, W.L.: Roll coating of purely viscous liquids. Chem. Eng. Sci. 36, 429–434 (1981)

Benkreira, H., Patel, R.: Direct gravure roll coating. Chem. Eng. Sci. 48, 2329–2335 (1993)

Bijsterbosch, H., Gaymans, R.J.: Impregnation of glass rovings with a polyamide melt. Part 1: impregnation bath. Compos. Part A-Appl. S. 4, 85–92 (1993)

Carvalho, M.S., Scriven, L.E.: Deformable roll coating flows: steady state and linear perturbation analysis. J. Fluid Mech. 339, 143–172 (1997)

Carvalho, M.S., Scriven, L.E.: Flows in forward deformable roll coating gaps: comparison between spring and plane-strain models or roll cover. J. Comput. Phys. 138, 449–479 (1997)

Carvalho, M.S.: Effect of thickness and viscoelastic properties of roll cover on deformable roll coating flows. Chem. Eng. Sci. 58, 4323–4333 (2003)

Chen, K.S.A., Scriven, L.E.: Liquid penetration into a deformable porous substrate. Tappi J. 73, 151–161 (1990)

Cohu, O., Magnin, A.: Forward roll coating of Newtonian fluids with deformable rolls: an experimental investigation. Chem. Eng. Sci 52, 1339–1347 (1997)

Coyle, D.J.: Forward roll coating with deformable rolls: a simple one dimensional elastohydrodynamic model. Chem. Eng. Sci. 43, 2673–2684 (1988)

Coyle, D.J., Macosko, C.W., Scriven, L.E.: The fluid dynamics of reverse roll coating. AIChE J. 36, 161–174 (1990)

Devisetti, S.K., Bousfield, D.W.: Fluid absorption during forward roll coating on porous webs. Chem. Eng. Sci. 65, 3528–3537 (2010)

Ding, X., Fuller, T.F., Harris, T.A.L.: Predicting fluid penetration during slot die coating onto porous substrates. Chem. Eng. Sci. 99, 67–75 (2013)

Ding, X., Ebin, J.P., Harris, T.A.L., Li, Z., Fuller, T.F.: Analytical models for predicting penetration depth during slot die coating onto porous media. AIChE J. 60, 4241–4252 (2014)

Farboodmanesh, S., Chen, J., Mead, J.L., White, K.D., Yesilalan, H.E., Laoulache, R., Warner, S.B.: Effect of coating thickness and penetration on shear behavior of coated fabrics. J. Elastom. Plast. 37, 197–227 (2005)

Gaymans, R.J., Wevers, E.: Impregnation of a glass fibre roving with a polypropylene melt in a pin assisted process. Compos. Part A-Appl. S. 29, 663–670 (1998)

Gibson, A.G., Månson, J.A.: Impregnation technology for thermoplastic matrix composites. Compos. Part A-Appl. S. 3, 223–233 (1992)

Gostling, M.J., Savage, M.D., Young, A.E., Gaskell, P.H.: A model for deformable roll coating with negative gaps and incompressible compliant layers. J. Fluid Mech. 489, 155–184 (2003)

Hayes, R.E., Bertrand, F.H., Tanguy, P.A.: Modeling of fluid/paper interaction in the application nip of a film coater. Transport Porous Med 40, 55–72 (2000)

Hewson, R.W., Kapur, N., Gaskell, P.H.: A two-scale model for discrete cell gravure roll coating. Chem. Eng. Sci. 66, 3666–3674 (2011)

Jones, M.B., Fulford, G.R., Please, C.P., McElwain, D.L.S., Collins, M.J.: Elastohydrodynamics of the Eyelid Wiper. Bull. Math. Biol 70, 323–343 (2008)

Kapur, N.: A parametric study of direct gravure coating. Chem. Eng. Sci. 58, 2875–2882 (2003)

Leal, L.: Advanced Transport Phenomena: Fluid Mechanics and Convective Transport Properties. Cambridge University Press, New York (2007)

Lécuyer, H.A., Mmbaga, J.P., Hayes, R.E., Bertrand, F.H., Tanguy, P.A.: Modeling of forward roll coating flows with a deformable roll: application to non-Newtonian industrial coating formulations. Comput. Chem. Eng. 33, 1427–1437 (2009)

Lee, S., Na, Y.: Effect of roll patterns on the ink transfer in R2R printing process. Int. J. Precis. Eng. Man. 10, 123–130 (2009)

Lundström, T.S., Hellström, J.G.I., Frishfelds, V.: Transversal flow-induced deformation of fibres during composites manufacturing and the effect of permeability. J. Reinf. Plast. Comp. 32, 1129–1135 (2013)

Madasu, S., Cairncross, R.A.: Effect of substrate flexibility on dynamic wetting: a finite element model. Comput. Methods Appl. Mech. Engrgy 192, 2671–2702 (2003)

Madasu, S.: Effect of soluble surfactants on dynamic wetting of flexible substrates: a finite element study. Phys. Fluids 21, 122103 (2009)

Matilainen, K., Hämäläinen, T., Savolainen, A., Sipiläinen-Malm, T., Peltonen, J., Erho, T., Smolander, M.: Performance and penetration of laccase and ABST inks on various printing substrates. Colloids Surf. B 90, 119–128 (2012)

Middleman, S.: Modeling Axisymmetric Flows: Dynamics of Films. Jets and Drops, San Diego (1995)

Nam, J., Carvalho, M.S.: Flow in tensioned-web-over-slot die coating: effect of die lip design. Chem. Eng. Sci. 65, 3957–3971 (2010)

Polychronopoulos, N.D., Papathanasiou, T.D.: Pin-assisted resin infiltration of porous substrates. Compos. Part A-Appl. S. 71, 126–135 (2015)

Ramon, G.Z., Huppert, H.E., Lister, J.R., Stone, H.A.: On the hydrodynamic interaction between a particle and a permeable surface. Phys. Fluids 25, 073103 (2013)

Romero, O.J., Suszynski, W.J., Scriven, L.E., Carvalho, M.S.: Low-flow limit in slot coating of dilute solutions of high molecular weight polymer. J. Non-Newt. Fluid Mech. 118, 137–156 (2004)

Sandström, A., Dam, H.F., Krebs, F.C., Edman, L.: Ambient fabrication of flexible and large-area organic light-emitting devices using slot-die coating. Nat. Commun. 3, 1–5 (2012)

Shampine, L., Kierzenka, J., Reichelt, M.: Solving Boundary Values Problems for ordinary Differential Equations in MATLAB with bvp4C. The MathWorks Inc. http://www.mathworks.com/bvp_tutorial (2000)

Skotheim, J.M., Mahadevan, L.: Soft lubrication. Phys. Rev. Lett. 92, 245509 (2004)

Skotheim, J.M., Mahadevan, L.: Soft lubrication: the elastohydrodynamics of nonconforming and conforming contacts. Phys. Fluids 17, 092101 (2005)

Sullivan, T., Middleman, S., Keunings, R.: Use of a finite element method to interpret rheological effects in blade coating. AIChE J. 33, 2047–2056 (1987)

Toll, S.: Packing Mechanics of fiber reinforcements. Pol. Eng. Sci. 38, 1337–1350 (1998)

Yesilalan, H.E., Warner, S.B., Laoulache, R.: Penetration of blade-applied viscous coatings into yarns in a woven fabric. Text. Res. J. 80, 1930–1941 (2010)

Yin, X., Kumar, S.: Lubrication flow between a cavity and a flexible wall. Phys. Fluids 17, 063101 (2005)

Yin, X., Kumar, S.: Two-dimensional simulations of flow near a cavity and a flexible solid boundary. Phys. Fluids 18, 063103 (2006)

Acknowledgments

We thank one of the reviewers for valuable feedback on non-dimensionalization of the model equations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Polychronopoulos, N.D., Papathanasiou, T.D. Fluid Penetration in a Deformable Permeable Web Moving Past a Stationary Rigid Solid Cylinder. Transp Porous Med 116, 393–411 (2017). https://doi.org/10.1007/s11242-016-0780-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-016-0780-1