Abstract

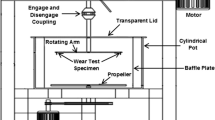

Based on the self-developed experimental apparatus, the wet steam erosion experiments were performed on polished steel specimens. Scanning Electronic Microscope (SEM) and Atomic Force Microscope (AFM) were used to identify the pit characteristics. The experimental results showed that there was little damage on the surface after being impacted by wet steam erosion. However, when the micro-particles were added into the wet steam, not only indentations and scratches but also craters appeared on the eroded surface. Some characteristics of crater, such as the circular shape and intergranular fractures, make the damages distinguish from those of the water-drop or micro-particle impact to solid wall, and they are considered as the results of cavitation erosion.

Similar content being viewed by others

References

Mukhopadhyay, N.K., Ghosh, S., Das, G., Chattoraj, I., Das, S.K., Bhattacharya, D.K.: An investigation of the failure of low pressure steam turbine blades. Eng. Fail. Anal. 15, 191–193 (1998)

Stanisa, B., Ivusic, V.: Erosion behaviour and mechanisms for steam turbine rotor blades. Wear 186–187, 395–400 (1995)

Obara, T., Bourne, N.K., Field, J.E.: Liquid-jet impact on liquid and solid surfaces. Wear 186–187, 388–394 (1995)

Mann, B.S., Vivek, A.: An experimental study to correlate water jet impingement erosion resistance and properties of metallic materials and coatings. Wear 253, 650–661 (2002)

Hutchings I.M., Winter R.E., Field J.E.: Solid particle erosion of metals: the removal of surface material by spherical projectiles. Proc. R. Soc. Lond. Ser. A 348, 379 (1976)

Hutchings, I.M., Macmillan, N.H., Rickerby, D.R.: Further studies of the oblique impact of a hard sphere against a ductile solid. Int. J. Mech. Sci. 23, 639–646 (1981)

Alfonso, C.A., Armando, G.M., Romero, C.A., Zdzislaw, M.C., Rafael, C.A.: Numerical investigation of the solid particle erosion rate in a steam turbine nozzle. Appl. Therm. Eng. 27, 2394–2403 (2007)

Ahmad, M., Casey, M., Suken, N.: Experimental assessment of droplet impact erosion resistance of steam turbine blade materials. Wear 267, 1605–1618 (2009)

Mann, B.S.: Solid-particle erosion and protective layers for steam turbine blading. Wear 224, 8–12 (1999)

Momber, A.W., Kwak, H., Kovacevic, R.: Investigations in abrasive water jet erosion based on wear particle analysis. J. Tribol. 118, 759–766 (1996)

Wang, J.D., Chen, H.S., Qin, L., Li, Y.J., Chen, D.R.: Key roles of micro-particles in water on occurrence of cavitation-erosion of hydro-machinery. Chin. Sci. Bull. 50, 1603–1607 (2008)

Kenndey, C.F., Field, J.E.: Damage threshold velocity for liquid impact. J. Mater. Sci. 35, 5331–5339 (2000)

Min, K.L., Whung, W.K., Chang, K.R.: Investigation of liquid impact erosion for 12Cr steel and stellite 6B. J. Nucl. Mater. 257, 134–144 (1998)

Li, Y.J.: Study on mechanism of surface topograhpy effects on generation of cavitation erosion. Doctoral Dissertation of Tsinghua University, Beijing (2008)

Rickard, G., Staffan, J.: The particle size effect in abrasion studied by controlled abrasive surfaces. Wear 224, 118–225 (1999)

Karimi, A., Avella, F.: Ripple formation in solid-liquid erosion. Wear 156, 33–47 (1992)

Lesser, M., Field, J.: The impact of compressible liquids. Annu. Rev. Fluid Mech. 15, 97–122 (1983)

Lesser M.B.: Analytic solutions of liquid-drop impact problems. Proc. R. Soc. Lond. Ser. A 377, 289–308 (1981)

Chang, L.C., Hsui, I.C., Chen, L.H., Lui, T.S.: A study on particle erosion behavior of ductile irons. Scripta Mater. 52, 609–613 (2005)

Huan, J.T.: The principle and application of cavitation and cavitation erosion. Tsinghua University publishing house, Beijing (1991)

Buravova, S.N.: Surface damage as a result of cavitation erosion. Tech. Phys. 43, 1107–1110 (1998)

Acknowledgments

The Project (Grant No. 2007CB707702) supported by the State Key Development Program for Basic Research of China, Project (Grant No. 20070003103) supported by the Research Fund for the Doctoral Program of Higher Education, and Project (Grant No. 50721004) supported by the National Natural Science Foundation of China are thanked. Also, the authors would also like to thank Yang Wenyan (Tsinghua University) for her help in SEM pictures.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, W., Wang, J., Qin, L. et al. Investigation of Erosion Damages Induced by Wet Steam Containing Micro-Particles. Tribol Lett 39, 115–120 (2010). https://doi.org/10.1007/s11249-010-9599-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9599-z