Abstract

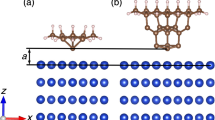

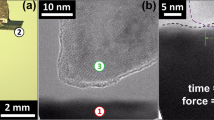

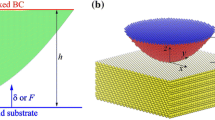

The effect of atomic-scale roughness on adhesion between carbon-based materials is examined by both simulations and experimental techniques. Nanoscale asperities composed of either diamond-like carbon or ultrananocrystalline diamond are brought into contact and then separated from diamond surfaces using both molecular dynamics simulations and in situ transmission electron microscope (TEM)-based nanoindentation. Both techniques allow for characterization of the roughness of the sharp nanoasperities immediately before and after contact down to the subnanometer scale. The root mean square roughness for the simulated tips spanned 0.03 nm (atomic corrugation) to 0.12 nm; for the experimental tips, the range was 0.18–1.58 nm. Over the tested range of roughness, the measured work of adhesion was found to decrease by more than an order of magnitude as the roughness increased. The dependence of adhesion upon roughness was accurately described using a simple analytical model. This combination of simulation and experimental methodologies allows for an exploration of an unprecedented range of tip sizes and length scales for roughness, while also verifying consistency of the results between the techniques. Collectively, these results demonstrate the high sensitivity of adhesion to interfacial roughness down to the atomic limit. Furthermore, they indicate that care must be taken when attempting to extract work of adhesion values from experimental measurements of adhesion forces.

Similar content being viewed by others

References

Israelachvili, J.N.: Intermolecular and Surface Forces, 3rd edn. Elsevier, San Francisco (2010)

Derjaguin, B.V., Muller, V., Toporov, Y.P.: Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 53, 314–326 (1975)

Johnson, K.L., Kendall, K., Roberts, A.D.: Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A 324, 301–313 (1971)

Maugis, D.: Adhesion of spheres: the JKR-DMT transition using a Dugdale model. J. Colloid Interface Sci. 150, 243–269 (1992)

Volinsky, A.A., Moody, N.R., Gerberich, W.W.: Interfacial toughness measurements for thin films on substrates. Acta Mater. 50, 441–466 (2002)

Gao, H., Wang, X., Yao, H., Gorb, S., et al.: Mechanics of hierarchical adhesion structures of geckos. Mech. Mater. 37, 275–285 (2005)

Finnis, M.W.: The theory of metal-ceramic interfaces. J. Phys. Condens. Matter 8, 5811 (1999)

Maboudian, R.: Critical review: adhesion in surface micromechanical structures. J. Vac. Sci. Technol. B 15, 1 (1997)

Grierson, D., Flater, E., Carpick, R.: Accounting for the JKR-DMT transition in adhesion and friction measurements with atomic force microscopy. J. Adhes. Sci. Technol. 19, 291–311 (2005)

Fuller, K., Tabor, D.: Effect of surface-roughness on adhesion of elastic solids. Proc. R. Soc. Lond. A 345, 327–342 (1975)

DelRio, F.W., de Boer, M.P., Knapp, J.A., Reedy, E.D., et al.: The role of van der Waals forces in adhesion of micromachined surfaces. Nat. Mater. 4, 629–634 (2005)

Tayebi, N., Polycarpou, A.A.: Reducing the effects of adhesion and friction in microelectromechanical systems (MEMSs) through surface roughening: comparison between theory and experiments. J. Appl. Phys. 98, 073528 (2005)

Ramakrishna, S.N., Clasohm, L.Y., Rao, A., Spencer, N.D.: Controlling adhesion force by means of nanoscale surface roughness. Langmuir 27, 9972–9978 (2011)

Segeren, L., Siebum, B., Karssenberg, F.G., Van den Berg, J., et al.: Microparticle adhesion studies by atomic force microscopy. J. Adhes. Sci. Technol. 16, 793–828 (2002)

Katainen, J., Paajanen, M., Ahtola, E., Pore, V., et al.: Adhesion as an interplay between particle size and surface roughness. J. Colloid Interface Sci. 304, 524–529 (2006)

Liu, D.L., Martin, J., Burnham, N.A.: Which fractal parameter contributes most to adhesion? J. Adhes. Sci. Technol. 24, 2383–2396 (2010)

Greenwood, J., Williamson, J.: Contact of nominally flat surfaces. Proc. R. Soc. Lond. A 295, 300–319 (1966)

Maugis, D.: On the contact and adhesion of rough surfaces. J. Adhes. Sci. Technol. 10, 161–175 (1996)

Peressadko, A., Hosoda, N., Persson, B.: Influence of surface roughness on adhesion between elastic bodies. Phys. Rev. Lett. 95, 124301 (2005)

Rumpf, H.: Particle Technology. Chapman and Hall, London (1990)

Rabinovich, Y.: Adhesion between nanoscale rough surfaces I. Role of asperity geometry. J. Colloid Interface Sci. 232, 10–16 (2000)

Mulakaluri, N., Persson, B.: Adhesion between elastic solids with randomly rough surfaces: comparison of analytical theory with molecular-dynamics simulations. Europhys. Lett. 96, 66003 (2011)

Luan, B., Robbins, M.: Contact of single asperities with varying adhesion: comparing continuum mechanics to atomistic simulations. Phys. Rev. E 74, 026111 (2006)

Piotrowski, P.L., Cannara, R.J., Gao, G., Urban, J.J., et al.: Atomistic factors governing adhesion between diamond, amorphous carbon and model diamond nanocomposite surfaces. J. Adhes. Sci. Technol. 24, 2471–2498 (2010)

Liu, J., Grierson, D., Moldovan, N., Notbohm, J., et al.: Preventing nanoscale wear of atomic force microscopy tips through the use of monolithic ultrananocrystalline diamond probes. Small 6, 1140–1149 (2010)

Goglia, P.R., Berkowitz, J., Hoehn, J., Xidis, A., et al.: Diamond-like carbon applications in high density hard disc recording heads. Diam. Relat. Mater. 10, 271–277 (2001)

Krauss, A.R., Auciello, O., Gruen, D.M., Jayatissa, A., et al.: Ultrananocrystalline diamond thin films for MEMS and moving mechanical assembly devices. Diam. Relat. Mater. 10, 1952–1961 (2001)

Greenwood, J.: Adhesion of elastic spheres. Proc. R. Soc. Lond. A 453, 1277–1297 (1997)

Yu, N., Polycarpou, A.A.: Adhesive contact based on the Lennard–Jones potential: a correction to the value of the equilibrium distance as used in the potential. J. Colloid Interface Sci. 278, 428–435 (2004)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, London (2011)

Adelman, S.A.: Generalized Langevin equation approach for atom/solid-surface scattering: general formulation for classical scattering off harmonic solids. J. Chem. Phys. 64, 2375 (1976)

Auciello, O., Birrell, J., Carlisle, J.A., Gerbi, J.E., et al.: Materials science and fabrication processes for a new MEMS technology based on ultrananocrystalline diamond thin films. J. Phys. Condens. Matter 16, R539–R552 (2004)

Stuart, S., Tutein, A., Harrison, J.: A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 112, 6472–6486 (2000)

LAMMPS Molecular Dynamics Simulator. http://lammps.sandia.gov/

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1–19 (1995)

Brenner, D.W., Shenderova, O.A., Harrison, J.A., Stuart, S.J., et al.: A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys. Condens. Matter 14, 783–802 (2002)

Harrison, J.A., Schall, J.D., Knippenberg, M.T., Gao, G., et al.: Elucidating atomic-scale friction using molecular dynamics and specialized analysis techniques. J. Phys. Condens. Matter 20, 354009 (2008)

Mikulski, P.T., Gao, G., Chateauneuf, G.M., Harrison, J.A.: Contact forces at the sliding interface: mixed versus pure model alkane monolayers. J. Chem. Phys. 122, 024701 (2005)

Knippenberg, M., Mikulski, P., Dunlap, B., Harrison, J.: Atomic contributions to friction and load for tip–self-assembled monolayers interactions. Phys. Rev. B 78, 235409 (2008)

Humphrey, W., Dalke, A., Schulten, K.: VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996)

Sumant, A.V., Grierson, D.S., Gerbi, J.E., Carlisle, J.A., et al.: Surface chemistry and bonding configuration of ultrananocrystalline diamond surfaces and their effects on nanotribological properties. Phys. Rev. B. 76, 235429 (2007)

Liu, J., Grierson, D.S., Sridharan, K., Carpick, R.W., et al.: Assessment of the mechanical integrity of silicon and diamond-like-carbon coated silicon atomic force microscope probes. In: Proceedings of the SPIE–The International Society for Optical Engineering, vol. 7767, p. 776708 (2010)

Bares, J.A., Sumant, A.V., Grierson, D.S., Carpick, R.W., et al.: Small amplitude reciprocating wear performance of diamond-like carbon films: dependence of film composition and counterface material. Tribol. Lett. 27, 79–88 (2007)

Fletcher, P.C., Felts, J.R., Dai, Z., Jacobs, T.D., et al.: Wear-resistant diamond nanoprobe tips with integrated silicon heater for tip-based nanomanufacturing. Am. Chem. Soc. Nano 4, 3338–3344 (2010)

Sader, J., Chon, J., Mulvaney, P.: Calibration of rectangular atomic force microscope cantilevers. Rev. Sci. Instrum. 70, 3967–3969 (1999)

Szlufarska, I., Chandross, M., Carpick, R.W.: Recent advances in single-asperity nanotribology. J. Phys. D-Appl. Phys. 41, 123001 (2008)

Acknowledgments

The authors wish to thank Dr. Doug Yates and Dr. Ryan Major for microscopy and equipment assistance, and Prof. Mark O. Robbins for helpful discussions. The authors thank Graham E. Wabiszewski for assistance performing AFM on the indenter tip. Use of the facilities of the Pennsylvania Regional Nanotechnology Facility is acknowledged. The authors acknowledge funding from the National Science Foundation under the following Grants: CMMI 0826076 (RWC); IGERT DGE 0221664 (TDBJ); DMR 1120901 (RWC); CMMI 0845294 (KTT); CMMI 0825981 (JAH, PLK, KER); CMMI 1200019 (KTT, RWC); CMMI 1200011 (JAH); and IAA 1129629 (JAH, PLK, KER). KER and PLK also acknowledge partial support from the Office of Naval Research through the US Naval Academy. The support of AFOSR under Contract No. FA2386-11-1-4105 AOARD is also acknowledged (RWC).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (MOV 225558 kb)

Rights and permissions

About this article

Cite this article

Jacobs, T.D.B., Ryan, K.E., Keating, P.L. et al. The Effect of Atomic-Scale Roughness on the Adhesion of Nanoscale Asperities: A Combined Simulation and Experimental Investigation. Tribol Lett 50, 81–93 (2013). https://doi.org/10.1007/s11249-012-0097-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-0097-3