Abstract

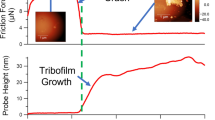

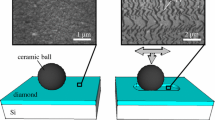

A custom-grown silicon and oxygen-containing hydrogenated amorphous carbon (a-C:H:Si:O) film is subjected to ball-on-flat tribometry under controlled sliding environments (ambient, dry air, and dry N2) at room temperature using a 52100 steel ball. The resulting friction coefficient is below 0.2 in ambient air and below 0.1 in dry N2. Tribofilms on the steel ball with thicknesses in excess of 500 nm are observed. The tribofilms are derived from the a-C:H:Si:O and grow on the steel ball, and display chemical and structural modifications relative to the original a-C:H:Si:O film. Sliding of the tribofilm-coated steel ball against bare silicon results in low friction, highlighting the inherent lubricity afforded by the tribofilm. Tribofilms grown through sliding against a-C:H:Si:O are characterized, post-sliding, with multiple spectroscopic and imaging techniques which collectively demonstrate that the composition and structure of the tribofilm is strongly dependent on the sliding environment. The unusually high tribofilm thickness allows for nanoindentation analysis, which demonstrates that the films are laterally heterogenous and softer than the original a-C:H:Si:O, with moduli and hardness values ranging over three orders of magnitude. Many regions of the tribofilms are extremely soft, with measured hardness values below 100 MPa and reduced Young’s moduli below 1 GPa, and also show a viscous mechanical response. Transmission electron microscopy and electron energy loss spectroscopy (TEM/EELS) characterization of the tribofilm demonstrates that the bulk structure is not graphitic, and indicates the tribofilms are enriched in C−H bonding. Additionally, there is a marked segregation within the tribofilm of Si/O and carbon. It is proposed that a primarily polymeric tribofilm structure can explain the observed mechanical properties.

Similar content being viewed by others

References

Ferrari, A.C.: Diamond-like carbon for magnetic storage disks. Surf. Coat. Technol. 180–181, 190–206 (2004). https://doi.org/10.1016/j.surfcoat.2003.10.146

Hainsworth, S.V., Uhure, N.J.: Diamond like carbon coatings for tribology: production techniques, characterisation methods and applications. Int. Mater. Rev. 52, 153–174 (2007). https://doi.org/10.1179/174328007X160272

Donnet, C., Erdemir, A.: Tribology of diamond-like carbon films fundamentals and applications. Springer, New York (2008)

Grischke, M., Bewilogua, K., Trojan, K., Dimigen, H.: Application-oriented modifications of deposition processes for diamond-like-carbon-based coatings. Surf. Coat. Technol. 74, 739–745 (1995). https://doi.org/10.1016/0257-8972(94)08201-4

Visser, S.A., Hewitt, C.E., Fornalik, J., Braunstein, G., Srividya, C., Babu, S.V.: Compositions and surface energies of plasma-deposited multilayer fluorocarbon thin films. Surf. Coat. Technol. 96, 210–222 (1997). https://doi.org/10.1016/S0257-8972(97)00112-6

Allen, M., Myer, B., Rushton, N.: In vitro and in vivo investigations into the biocompatibility of diamond-like carbon (DLC) coatings for orthopedic applications. J. Biomed. Mater. Res. 58, 319–328 (2001). https://doi.org/10.1002/1097-4636(2001)58:3%3C319::AID-JBM1024%3E3.0.CO;2-F

Koshigan, K.D., Mangolini, F., McClimon, J.B., Vacher, B., Bec, S., Carpick, R.W., Fontaine, J.: Understanding the hydrogen and oxygen gas pressure dependence of the tribological properties of silicon oxide–doped hydrogenated amorphous carbon coatings. Carbon. 93, 851–860 (2015). https://doi.org/10.1016/j.carbon.2015.06.004

Yang, W.J., Choa, Y.-H., Sekino, T., Shim, K.B., Niihara, K., Auh, K.H.: Thermal stability evaluation of diamond-like nanocomposite coatings. Thin Solid Films. 434, 49–54 (2003). https://doi.org/10.1016/S0040-6090(03)00466-8

Mangolini, F., McClimon, J.B., Segersten, J., Hilbert, J., Heaney, P., Lukes, J.R., Carpick, R.W.: Silicon oxide-rich diamond-like carbon: a conformal, ultrasmooth thin film material with high thermo-oxidative stability. Adv. Mater. Interfaces. 0, 1801416. https://doi.org/10.1002/admi.201801416

Mangolini, F., Rose, F., Hilbert, J., Carpick, R.W.: Thermally induced evolution of hydrogenated amorphous carbon. Appl. Phys. Lett. 103, 161605 (2013). https://doi.org/10.1063/1.4826100

Konicek, A.R.: Influence of surface passivation on the friction and wear behavior of ultrananocrystalline diamond and tetrahedral amorphous carbon thin films. Phys. Rev. B 85, (2012). https://doi.org/10.1103/PhysRevB.85.155448

Donnet, C., Fontaine, J., Grill, A., Mogne, T.L.: The role of hydrogen on the friction mechanism of diamond-like carbon films. Tribol. Lett. 9, 137–142 (2001). https://doi.org/10.1023/A:1018800719806

Qi, Y., Konca, E., Alpas, A.T.: Atmospheric effects on the adhesion and friction between non-hydrogenated diamond-like carbon (DLC) coating and aluminum—a first principles investigation. Surf. Sci. 600, 2955–2965 (2006). https://doi.org/10.1016/j.susc.2006.05.008

Cui, L., Lu, Z., Wang, L.: Probing the low-friction mechanism of diamond-like carbon by varying of sliding velocity and vacuum pressure. Carbon. 66, 259–266 (2014). https://doi.org/10.1016/j.carbon.2013.08.065

Romero, P.A., Pastewka, L., Lautz, J.V., Moseler, M.: Surface passivation and boundary lubrication of self-mated tetrahedral amorphous carbon asperities under extreme tribological conditions. Friction. 2, 193–208 (2014). https://doi.org/10.1007/s40544-014-0057-z

Wang, L., Cui, L., Lu, Z., Zhou, H.: Understanding the unusual friction behavior of hydrogen-free diamond-like carbon films in oxygen atmosphere by first-principles calculations. Carbon. 100, 556–563 (2016). https://doi.org/10.1016/j.carbon.2016.01.060

Kajita, S., Righi, M.C.: A fundamental mechanism for carbon-film lubricity identified by means of ab initio molecular dynamics. Carbon. https://doi.org/10.1016/j.carbon.2016.02.078

Matta, C., Eryilmaz, O.L., Bouchet, M.I.D.B., Erdemir, A., Martin, J.M., Nakayama, K.: On the possible role of triboplasma in friction and wear of diamond-like carbon films in hydrogen-containing environments. J. Phys. Appl. Phys. 42, 075307 (2009). https://doi.org/10.1088/0022-3727/42/7/075307

Konicek, A.R.: Origin of Ultralow Friction and Wear in Ultrananocrystalline Diamond. Phys. Rev. Lett. 100, (2008). https://doi.org/10.1103/PhysRevLett.100.235502

Liu, Y., Erdemir, A., Meletis, E.I.: An investigation of the relationship between graphitization and frictional behavior of DLC coatings. Surf. Coat. Technol. 86, 564–568 (1996). https://doi.org/10.1016/S0257-8972(96)03057-5

Scharf, T.W., Ohlhausen, J.A., Tallant, D.R., Prasad, S.V.: Mechanisms of friction in diamondlike nanocomposite coatings. J. Appl. Phys. 101, 063521–063521 (2007). https://doi.org/10.1063/1.2711147

Ahn, H.-S., Chizhik, S.A., Dubravin, A.M., Kazachenko, V.P., Popov, V.V.: Application of phase contrast imaging atomic force microscopy to tribofilms on DLC coatings. Wear. 249, 617–625 (2001). https://doi.org/10.1016/S0043-1648(01)00694-9

Rabbani, F.: Phenomenological evidence for the wear-induced graphitization model of amorphous hydrogenated carbon coatings. Surf. Coat. Technol. 184, 194–207 (2004). https://doi.org/10.1016/j.surfcoat.2003.11.006

Kunze, T., Posselt, M., Gemming, S., Seifert, G., Konicek, A.R., Carpick, R.W., Pastewka, L., Moseler, M.: Wear, Plasticity, and Rehybridization in Tetrahedral Amorphous Carbon. Tribol. Lett. 53, 119–126 (2014). https://doi.org/10.1007/s11249-013-0250-7

Chen, X., Zhang, C., Kato, T., Yang, X., Wu, S., Wang, R., Nosaka, M., Luo, J.: Evolution of tribo-induced interfacial nanostructures governing superlubricity in a-C:H and a-C:H:Si films. Nat. Commun. 8, 1675 (2017). https://doi.org/10.1038/s41467-017-01717-8

Goto, M., Ito, K., Fontaine, J., Takeno, T., Miki, H., Takagi, T.: Formation Processes of Metal-Rich Tribofilm on the Counterface During Sliding Against Metal/Diamondlike-Carbon Nanocomposite Coatings. Tribol. Online. 10, 306–313 (2015). https://doi.org/10.2474/trol.10.306

Qin, W., Yue, W., Wang, C.: Understanding integrated effects of humidity and interfacial transfer film formation on tribological behaviors of sintered polycrystalline diamond. RSC Adv. 5, 53484–53496 (2015). https://doi.org/10.1039/C5RA09327A

Zhang, X., Schneider, R., Müller, E., Mee, M., Meier, S., Gumbsch, P., Gerthsen, D.: Electron microscopic evidence for a tribologically induced phase transformation as the origin of wear in diamond. J. Appl. Phys. 115, 063508 (2014). https://doi.org/10.1063/1.4865742

De Barros Bouchet, M.I., Matta, C., Vacher, B., Le-Mogne, T., Martin, J.M., von Lautz, J., Ma, T., Pastewka, L., Otschik, J., Gumbsch, P., Moseler, M.: Energy filtering transmission electron microscopy and atomistic simulations of tribo-induced hybridization change of nanocrystalline diamond coating. Carbon. 87, 317–329 (2015). https://doi.org/10.1016/j.carbon.2015.02.041

Fontaine, J., Loubet, J.L., Mogne, T.L., Grill, A.: Superlow friction of diamond-like carbon films: a relation to viscoplastic properties. Tribol. Lett. 17, 709–714 (2004). https://doi.org/10.1007/s11249-004-8077-x

Menčík, J., Rauchs, G., Bardon, J., Riche, A.: Determination of elastic modulus and hardness of viscoelastic-plastic materials by instrumented indentation under harmonic load. J. Mater. Res. 20, 2660–2669 (2005). https://doi.org/10.1557/JMR.2005.0338

Langford, R.M., Petford-Long, A.K.: Preparation of transmission electron microscopy cross-section specimens using focused ion beam milling. J. Vac. Sci. Technol. A. 19, 2186–2193 (2001). https://doi.org/10.1116/1.1378072

Hart, J.L., Lang, A.C., Leff, A.C., Longo, P., Trevor, C., Twesten, R.D., Taheri, M.L.: Direct Detection Electron Energy-Loss Spectroscopy: A Method to Push the Limits of Resolution and Sensitivity. Sci. Rep. 7, 8243 (2017). https://doi.org/10.1038/s41598-017-07709-4

Ponsonnet, L., Donnet, C., Varlot, K., Martin, J.M., Grill, A., Patel, V.: EELS analysis of hydrogenated diamond-like carbon films. Thin Solid Films. 319, 97–100 (1998). https://doi.org/10.1016/S0040-6090(97)01094-8

Varlot, K., Martin, J.M., Quet, C., Kihn, Y.: Towards sub-nanometer scale EELS analysis of polymers in the TEM. Ultramicroscopy. 68, 123–133 (1997). https://doi.org/10.1016/S0304-3991(97)00019-3

Egerton, R.F.: Electron energy-loss spectroscopy in the TEM. Rep. Prog. Phys. 72, 016502 (2009). https://doi.org/10.1088/0034-4885/72/1/016502

Donnet, C., Mogne, T.L., Ponsonnet, L., Belin, M., Grill, A., Patel, V., Jahnes, C.: The respective role of oxygen and water vapor on the tribology of hydrogenated diamond-like carbon coatings. Tribol. Lett. 4, 259–265 (1998). https://doi.org/10.1023/A:1019140213257

Holmberg, K., Mathews, A.: Coatings tribology: a concept, critical aspects and future directions. Thin Solid Films. 253, 173–178 (1994). https://doi.org/10.1016/0040-6090(94)90315-8

Liu, S., Zhang, C., Osman, E., Chen, X., Ma, T., Hu, Y., Luo, J., Ali, E.: Influence of tribofilm on superlubricity of highly-hydrogenated amorphous carbon films in inert gaseous environments. Sci. China Technol. Sci. 1–9 (2016). https://doi.org/10.1007/s11431-016-0078-6

Wang, P., Hirose, M., Suzuki, Y., Adachi, K.: Carbon tribo-layer for super-low friction of amorphous carbon nitride coatings in inert gas environments. Surf. Coat. Technol. 221, 163–172 (2013). https://doi.org/10.1016/j.surfcoat.2013.01.045

Salvaro, D.B., Silvério, M., Binder, C., Giacomelli, R.O., Klein, A.N., de Mello, J.D.B.: Genesis and stability of tribolayers in solid lubrication: case of pair DLC-stainless steel. J. Mater. Res. Technol. 5, 136–143 (2016). https://doi.org/10.1016/j.jmrt.2015.10.008

Benedet, J., Green, J.H., Lamb, G.D., Spikes, H.A.: Spurious Mild Wear Measurement Using White Light Interference Microscopy in the Presence of Antiwear Films. Tribol. Trans. 52, 841–846 (2009). https://doi.org/10.1080/10402000903180696

Shuman, D.J., Costa, A.L.M., Andrade, M.S.: Calculating the elastic modulus from nanoindentation and microindentation reload curves. Mater. Charact. 58, 380–389 (2007). https://doi.org/10.1016/j.matchar.2006.06.005

Oliver, W.C., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992). https://doi.org/10.1557/JMR.1992.1564

Saraswati, T., Sritharan, T., Mhaisalkar, S., Breach, C.D., Wulff, F.: Cyclic loading as an extended nanoindentation technique. Mater. Sci. Eng. A. 423, 14–18 (2006). https://doi.org/10.1016/j.msea.2005.10.080

Chen, Z., Diebels, S., Peter, N.J., Schneider, A.S.: Identification of finite viscoelasticity and adhesion effects in nanoindentation of a soft polymer by inverse method. Comput. Mater. Sci. 72, 127–139 (2013). https://doi.org/10.1016/j.commatsci.2013.01.040

Pathak, S., Cambaz, Z.G., Kalidindi, S.R., Swadener, J.G., Gogotsi, Y.: Viscoelasticity and high buckling stress of dense carbon nanotube brushes. Carbon. 47, 1969–1976 (2009). https://doi.org/10.1016/j.carbon.2009.03.042

Chang, B.T.-A., Li, J.C.M.: Indentation recovery of amorphous materials. Scr. Metall. 13, 51–54 (1979). https://doi.org/10.1016/0036-9748(79)90388-0

Thompson, J.B., Kindt, J.H., Drake, B., Hansma, H.G., Morse, D.E., Hansma, P.K.: Bone indentation recovery time correlates with bond reforming time. Nature. 414, 773–776 (2001). https://doi.org/10.1038/414773a

Adams, M.J., Gorman, D.M., Johnson, S.A., Briscoe, B.J.: Indentation depth recovery in poly(methyl methacrylate) sheet on the microlength scale. Philos. Mag. A. 82, 2121–2131 (2002). https://doi.org/10.1080/01418610208235722

Guin, J.-P., Rouxel, T., Keryvin, V., Sanglebœuf, J.-C., Serre, I., Lucas, J.: Indentation creep of Ge–Se chalcogenide glasses below Tg: elastic recovery and non-Newtonian flow. J. Non-Cryst. Solids. 298, 260–269 (2002). https://doi.org/10.1016/S0022-3093(01)01053-5

Golovin, Y.I., Ivolgin, V.I., Ryabko, R.I.: Viscoelastic recovery of various materials in the region of a dynamic nanocontact. Tech. Phys. Lett. 30, 202–204 (2004). https://doi.org/10.1134/1.1707167

Tweedie, C.A., Van Vliet, K.J.: On the indentation recovery and fleeting hardness of polymers. J. Mater. Res. 21, 3029–3036 (2006). https://doi.org/10.1557/jmr.2006.0377

Trunov, M.L., Bilanich, V.S., Dub, S.N.: Nanoindentation study of the time-dependent mechanical behavior of materials. Tech. Phys. 52, 1298–1305 (2007). https://doi.org/10.1134/S1063784207100088

Golovin, Y.I.: Nanoindentation and mechanical properties of solids in submicrovolumes, thin near-surface layers, and films. A Review. Phys. Solid State. 50, 2205–2236 (2008). https://doi.org/10.1134/S1063783408120019

Bec, S., Tonck, A., Fontaine, J.: Nanoindentation and nanofriction on DLC films. Philos. Mag. 86, 5465–5476 (2006). https://doi.org/10.1080/14786430600596845

Walter, C., Mitterer, C.: 3D versus 2D finite element simulation of the effect of surface roughness on nanoindentation of hard coatings. Surf. Coat. Technol. 203, 3286–3290 (2009). https://doi.org/10.1016/j.surfcoat.2009.04.006

Kim, J.-Y., Lee, J.-J., Lee, Y.-H., Jang, J., Kwon, D.: Surface roughness effect in instrumented indentation: A simple contact depth model and its verification. J. Mater. Res. 21, 2975–2978 (2006). https://doi.org/10.1557/jmr.2006.0370

Bobji, M.S., Biswas, S.K., Pethica, J.B.: Effect of roughness on the measurement of nanohardness—a computer simulation study. Appl. Phys. Lett. 71, 1059–1061 (1997). https://doi.org/10.1063/1.119727

Lucas, B.N., Oliver, W.C., Pharr, G.M., Loubet, J.L.: Time Dependent Deformation During Indentation Testing. In: Symposium CC—Thin Films Stresses and Mechanical Properties VI: (1996)

Chong, A.C.M., Lam, D.C.C.: Strain gradient plasticity effect in indentation hardness of polymers. J. Mater. Res. 14, 4103–4110 (1999). https://doi.org/10.1557/JMR.1999.0554

Lam, D.C.C., Chong, A.C.M.: Indentation model and strain gradient plasticity law for glassy polymers. J. Mater. Res. 14, 3784–3788 (1999). https://doi.org/10.1557/JMR.1999.0512

Zhang, T.-Y., Xu, W.-H.: Surface Effects on Nanoindentation. J. Mater. Res. 17, 1715–1720 (2002). https://doi.org/10.1557/JMR.2002.0254

Cordill, M.J., Lund, M.S., Parker, J., Leighton, C., Nair, A.K., Farkas, D., Moody, N.R., Gerberich, W.W.: The Nano-Jackhammer effect in probing near-surface mechanical properties. Int. J. Plast. 25, 2045–2058 (2009). https://doi.org/10.1016/j.ijplas.2008.12.015

Siu, K.W., Ngan, A.H.W.: The continuous stiffness measurement technique in nanoindentation intrinsically modifies the strength of the sample. Philos. Mag. 93, 449–467 (2013). https://doi.org/10.1080/14786435.2012.722234

Cordill, M.J., Moody, N.R., Gerberich, W.W.: Effects of dynamic indentation on the mechanical response of materials. J. Mater. Res. 23, 1604–1613 (2008). https://doi.org/10.1557/JMR.2008.0205

Fielda, J.S., Swain, M.V.: The indentation characterisation of the mechanical properties of various carbon materials: Glassy carbon, coke and pyrolytic graphite. Carbon. 34, 1357–1366 (1996). https://doi.org/10.1016/S0008-6223(96)00071-1

Sakai, M., Nakano, Y.: Instrumented pyramidal and spherical indentation of polycrystalline graphite. J. Mater. Res. 19, 228–236 (2004). https://doi.org/10.1557/jmr.2004.19.1.228

Fu, W., Chung, D.D.L.: Vibration reduction ability of polymers, particularly polymethylmethacrylate and polytetrafluoroethylene. Polym. Polym. Compos. 9, 423–426 (2001)

Fontaine, J., Le Mogne, T., Loubet, J.L., Belin, M.: Achieving superlow friction with hydrogenated amorphous carbon: some key requirements. Thin Solid Films. 482, 99–108 (2005). https://doi.org/10.1016/j.tsf.2004.11.126

Hahn, J.R.: Kinetic study of graphite oxidation along two lattice directions. Carbon. 43, 1506–1511 (2005). https://doi.org/10.1016/j.carbon.2005.01.032

de Theije, F.K., Roy, O., van der Laag, N.J., van Enckevort, W.J.P.: Oxidative etching of diamond. Diam. Relat. Mater. 9, 929–934 (2000). https://doi.org/10.1016/S0925-9635(99)00239-3

Felts, J.R., Oyer, A.J., Hernández, S.C., Whitener, K.E. Jr., Robinson, J.T., Walton, S.G., Sheehan, P.E.: Direct mechanochemical cleavage of functional groups from graphene. Nat. Commun. 6, (2015). https://doi.org/10.1038/ncomms7467

Collom, S.L., Anastas, P.T., Beach, E.S., Crabtree, R.H., Hazari, N., Sommer, T.J.: Differing selectivities in mechanochemical versus conventional solution oxidation using Oxone. Tetrahedron Lett. 54, 2344–2347 (2013). https://doi.org/10.1016/j.tetlet.2013.02.056

Conway, N.M.J., Ferrari, A.C., Flewitt, A.J., Robertson, J., Milne, W.I., Tagliaferro, A., Beyer, W.: Defect and disorder reduction by annealing in hydrogenated tetrahedral amorphous carbon. Diam. Relat. Mater. 9, 765–770 (2000). https://doi.org/10.1016/S0925-9635(99)00271-X

Rose, F., Wang, N., Smith, R., Xiao, Q.-F., Inaba, H., Matsumura, T., Saito, Y., Matsumoto, H., Dai, Q., Marchon, B., Mangolini, F., Carpick, R.W.: Complete characterization by Raman spectroscopy of the structural properties of thin hydrogenated diamond-like carbon films exposed to rapid thermal annealing. J. Appl. Phys. 116, 123516 (2014). https://doi.org/10.1063/1.4896838

Ferrari, A.C., Robertson, J.: Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B. 61, 14095–14107 (2000). https://doi.org/10.1103/PhysRevB.61.14095

Cui, L., Zhou, H., Zhang, K., Lu, Z., Wang, X.: Bias voltage dependence of superlubricity lifetime of hydrogenated amorphous carbon films in high vacuum. Tribol. Int. https://doi.org/10.1016/j.triboint.2017.08.020

Ni, Z.H.: Raman spectroscopy of epitaxial graphene on a SiC substrate. Phys. Rev. B 77, (2008). https://doi.org/10.1103/PhysRevB.77.115416

Swain, B.P.: The analysis of carbon bonding environment in HWCVD deposited a-SiC:H films by XPS and Raman spectroscopy. Surf. Coat. Technol. 201, 1589–1593 (2006). https://doi.org/10.1016/j.surfcoat.2006.02.029

Lu, W., Feldman, L.C., Song, Y., Dhar, S., Collins, W.E., Mitchel, W.C., Williams, J.R.: Graphitic features on SiC surface following oxidation and etching using surface enhanced Raman spectroscopy. Appl. Phys. Lett. 85, 3495 (2004). https://doi.org/10.1063/1.1804610

Windl, W.: Second-order Raman spectra of SiC: experimental and theoretical results from ab initio phonon calculations. Phys. Rev. B. 49, 8764–8767 (1994). https://doi.org/10.1103/PhysRevB.49.8764

Swanson, N., Powell, C.J.: Excitation of π electrons in polystyrene and similar polymers by 20 keV electrons. J. Chem. Phys. 39, 630–634 (1963). https://doi.org/10.1063/1.1734302

Ferrari, A.C., Libassi, A., Tanner, B.K., Stolojan, V., Yuan, J., Brown, L.M., Rodil, S.E., Kleinsorge, B., Robertson, J.: Density, sp3 fraction, and cross-sectional structure of amorphous carbon films determined by X-ray reflectivity and electron energy-loss spectroscopy. Phys. Rev. B. 62, 11089–11103 (2000). https://doi.org/10.1103/PhysRevB.62.11089

Mangolini, F., Hilbert, J., McClimon, J.B., Lukes, J.R., Carpick, R.W.: Thermally induced structural evolution of silicon- and oxygen-containing hydrogenated amorphous carbon: a combined spectroscopic and molecular dynamics simulation investigation. Langmuir. 34, 2989–2995 (2018). https://doi.org/10.1021/acs.langmuir.7b04266

Fukui, H., Irie, M., Utsumi, Y., Oda, K., Ohara, H.: An investigation of the wear track on DLC (a-C:H) film by time-of-flight secondary ion mass spectroscopy. Surf. Coat. Technol. 146–147, 378–383 (2001). https://doi.org/10.1016/S0257-8972(01)01422-0

Chen, X., Kato, T., Nosaka, M.: Origin of superlubricity in a-C:H:Si films: a relation to film bonding structure and environmental molecular characteristic. ACS Appl. Mater. Interfaces. 6, 13389–13405 (2014). https://doi.org/10.1021/am502416w

Liu, Y., Meletis, E.I.: Evidence of graphitization of diamond-like carbon films during sliding wear. J. Mater. Sci. 32, 3491–3495 (1997). https://doi.org/10.1023/A:1018641304944

Koshigan, K.D.: Understanding the influence of environment on the solid lubrication processes of carbon-based thin films. Ecully, Ecole centrale de Lyon (2015)

Eryilmaz, O.L., Erdemir, A.: Surface analytical investigation of nearly-frictionless carbon films after tests in dry and humid nitrogen. Surf. Coat. Technol. 201, 7401–7407 (2007). https://doi.org/10.1016/j.surfcoat.2007.02.005

Sánchez-López, J.C., Belin, M., Donnet, C., Quirós, C., Elizalde, E.: Friction mechanisms of amorphous carbon nitride films under variable environments: a triboscopic study. Surf. Coat. Technol. 160, 138–144 (2002). https://doi.org/10.1016/S0257-8972(02)00397-3

Scharf, T.W., Prasad, S.V.: Solid lubricants: a review. J. Mater. Sci. 48, 511–531 (2013). https://doi.org/10.1007/s10853-012-7038-2

McGuiggan, P.M., Hsu, S.M., Fong, W., Bogy, D., Bhatia, C.S.: Friction measurements of ultra-thin carbon overcoats in air. J. Tribol. 124, 239–244 (1999). https://doi.org/10.1115/1.1387035

Pastewka, L., Robbins, M.O.: Contact area of rough spheres: large scale simulations and simple scaling laws. Appl. Phys. Lett. 108, 221601 (2016). https://doi.org/10.1063/1.4950802

Lin, Y.-H.: Polymer Viscoelasticity: Basics, Molecular Theories, Experiments and Simulations. World Scientific Publishing Company, New Jersey (2010)

Acknowledgements

This material is based upon work supported by the Advanced Storage Technology Consortium ASTC (Grant 2011-012), the National Science Foundation under Grant No. DMR-1107642, the National Science Foundation through the University of Pennsylvania Materials Research Science and Engineering Center (MRSEC) (DMR-1720530), and by the Agence Nationale de la Recherche under Grant No. ANR-11- NS09-01 through the Materials World Network program. Additional travel support was provided by Programme Avenir Lyon-Saint-Etienne and Region Rhône-Alpes. NSF Major Research Instrumentation Grant DMR-0923245 and use of the Scanning and Local Probe Facility of the Singh Center for Nanotechnology, which is supported by the NSF National Nanotechnology Coordinated Infrastructure Program under grant NNCI-1542153, are acknowledged. J.B.M. acknowledges support of a Graduate Research Supplement for Veterans from the Directorate for Mathematical and Physical Sciences at the National Science Foundation. MLT and ACL gratefully acknowledge funding from the National Science Foundation Major Instrumentation Award #1429661. The authors would like to thank Prof. Kevin Turner for use of the Hysitron TI-950 Triboindenter and Dr. Yijie Jiang for extensive training and assistance in the use of the indenter. The authors would also like to thank Michel Belin and Dr. Komlavi Dzidula Koshigan for instruction and advice in the use of the environmental tribometer. F.M. acknowledges support from the Marie Curie International Outgoing Fellowship for Career Development within the 7th European Community Framework Program under contract no. PIOF-GA-2012-328776 and the Marie Skłodowska-Curie Individual Fellowship within the European Union’s Horizon 2020 Program under contract no. 706289. The acquisition of the instrumentation used for this work was partially supported by the U.S. Department of Defense DURIP program under Air Force Grant FA9550-16-1-0525.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

McClimon, J.B., Lang, A.C., Milne, Z. et al. Investigation of the Mechanics, Composition, and Functional Behavior of Thick Tribofilms Formed from Silicon- and Oxygen-Containing Hydrogenated Amorphous Carbon. Tribol Lett 67, 48 (2019). https://doi.org/10.1007/s11249-019-1155-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-019-1155-x