Abstract

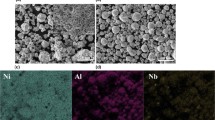

The tribological performance and friction-induced vibration of Gd0.2-Ce0.8O1.9 (GDC) reinforced nickel oxide (NiO) metal matrix composites prepared via sintering on the tribological performance, as well as friction induced vibration were investigated. Compared to pure NiO, the composites exhibit improved mechanical properties, such as a relatively high dislocation density, hardness and small grain size. The results show that GDC-reinforced NiO nanocomposites feature improved tribological performance and can suppress the occurrence of friction-induced vibration under variable loading conditions. Furthermore, the generated acceleration can be suppressed by wear particles generated during the friction process, acting as the third body at the contact interface. As a result, the addition of GDC reduces the grain size of the composite, increases hardness, and improves tribological properties through the synergetic effect of the solid lubricating action of NiO and the role of the third body of the wear particle.

Graphical Abstract

Similar content being viewed by others

References

Sheikh-Ahmad, J., Davim, J.P.: Tool wear in machining processes for composites. Machining technology for composite materials, pp. 116–153. Woodhead Publishing, Cambridge (2012)

Ibrahim, I., Mohamed, F., Lavernia, E.: Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 26(5), 1137–1156 (1991)

Aruna, S., et al.: Synthesis and properties of electrodeposited Ni/ceria nanocomposite coatings. Surf. Coat. Technol. 200(24), 6871–6880 (2006)

Hovestad, A., Janssen, L.: Electrochemical codeposition of inert particles in a metallic matrix. J. Appl. Electrochem. 25(6), 519–527 (1995)

Clauss, F.J.: Solid lubricants and self-lubricating solids. Academic press, Cambridge (1972)

Scharf, T., Prasad, S.: Solid lubricants: a review. J. Mater. Sci. 48(2), 511–531 (2013)

Flores, J., et al.: An experimental study of the erosion–corrosion behavior of plasma transferred arc MMCs. Wear 267(1–4), 213–222 (2009)

Rahman, M.S., et al.: Tribology of incoloy 800HT for nuclear reactors under helium environment at elevated temperatures. Wear 436, 203022 (2019)

Aruna, S., Grips, V.W., Rajam, K.: Ni-based electrodeposited composite coating exhibiting improved microhardness, corrosion and wear resistance properties. J. Alloys Compd. 468(1–2), 546–552 (2009)

Shu, D., et al.: In situ synthesized high volume fraction WC reinforced Ni-based coating by laser cladding. Mater. Lett. 195, 178–181 (2017)

Xuelong, P., et al.: Effect of Nb addition on microstructure and properties of laser cladding NiCrBSi coatings. Trans. IMF 96(6), 304–312 (2018). https://doi.org/10.1080/00202967.2018.1502934

Stott, F., Wood, G.: The influence of oxides on the friction and wear of alloys. Tribol. Int. 11(4), 211–218 (1978)

Hager, C., Jr., et al.: The mechanisms of gross slip fretting wear on nickel oxide/Ti6Al4V mated surfaces. Wear 268(9–10), 1195–1204 (2010)

Masouros, G., Dimarogonas, A., Lefas, K.: A model for wear and surface roughness transients during the running-in of bearings. Wear 45(3), 375–382 (1977)

Chen, L., et al.: Running-in process of Si-SiO x/SiO 2 pair at nanoscale—sharp drops in friction and wear rate during initial cycles. Friction 1(1), 81–91 (2013)

Chi, H., et al.: The tribological behavior evolution of TiB2/Al composites from running-in stage to steady stage. Wear 368, 304–313 (2016)

Marian, M., et al.: MXene nanosheets as an emerging solid lubricant for machine elements—towards increased energy efficiency and service life. Appl. Surf. Sci. 523, 146503 (2020)

Pattnaik, A.B., Das, S.: Probability of formation of wear debris during initial running-in period of sliding wear of Al-Si (LM13)-10 wt.% fly ash composites. J. Mater. Eng. Perform. 29(11), 7480–7487 (2020)

Nwanya, A.C., et al.: Zea mays lea silk extract mediated synthesis of nickel oxide nanoparticles as positive electrode material for asymmetric supercabattery. J. Alloys Compd. 822, 153581 (2020)

Tromans, D., Meech, J.: Fracture toughness and surface energies of minerals: theoretical estimates for oxides, sulphides, silicates and halides. Miner. Eng. 15(12), 1027–1041 (2002)

Phuong, D.D., et al.: Influence of sintering temperature on microstructure and mechanical properties of WC-8Ni cemented carbide produced by vacuum sintering. Ceram. Int. 42(13), 14937–14943 (2016)

Morales, M., et al.: Mechanical properties at the nanometer scale of GDC and YSZ used as electrolytes for solid oxide fuel cells. Acta Mater. 58(7), 2504–2509 (2010)

Muthukkumaran, K., et al.: Thermal properties of 15-mol% gadolinia doped ceria thin films prepared by pulsed laser ablation. Ionics 13(1), 47–50 (2007)

Lee, Y.H., et al.: Platinum-based nanocomposite electrodes for low-temperature solid oxide fuel cells with extended lifetime. J. Power Sources 307, 289–296 (2016)

Oliver, W.C., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564–1583 (1992)

Anstis, G., et al.: A critical evaluation of indentation techniques for measuring fracture toughness: i, direct crack measurements. J. Am. Ceram. Soc. 64(9), 533–538 (1981)

Chavan, A., et al.: Effect of variation of NiO on properties of NiO/GDC (gadolinium doped ceria) nano-composites. Ceram. Int. 38(4), 3191–3196 (2012)

Nafsin, N., et al.: Thermodynamics versus kinetics of grain growth control in nanocrystalline zirconia. Acta Mater. 136, 224–234 (2017)

Soares, M.R., et al.: Unraveling the role of Sn segregation in the electronic transport of polycrystalline hematite: raising the electronic conductivity by lowering the grain-boundary blocking effect. Adv. Electron. Mater. 5(6), 1900065 (2019)

Estrin, Y., Vinogradov, A.: Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61(3), 782–817 (2013)

Zehetbauer, M., Seumer, V.: Cold work hardening in stages IV and V of FCC metals—I. Experiments and interpretation. Acta Metal. Mater. 41(2), 577–588 (1993)

Pantleon, W.: Formation of disorientations in dislocation structures during plastic deformation. In: Solid state phenomena. Trans Tech Publications Ltd., Switzerland (2002)

Hadzima, B., et al.: Microstructure and corrosion behaviour of ultrafine-grained copper. In: Materials science forum. Trans Tech Publications Ltd., Switzerland (2006)

Shi, J., Zikry, M.: Grain size, grain boundary sliding, and grain boundary interaction effects on nanocrystalline behavior. Mater. Sci. Eng. A 520(1–2), 121–133 (2009)

Wang, A., et al.: Effect of surface roughness on friction-induced noise: exploring the generation of squeal at sliding friction interface. Wear 402, 80–90 (2018)

Wang, X., et al.: An investigation of stick-slip oscillation of Mn–Cu damping alloy as a friction material. Tribol. Int. 146, 106024 (2020)

Lu, G., et al.: Effects of functionally gradient structure of Ni3Al metal matrix self-lubrication composites on friction-induced vibration and noise and wear behaviors. Tribol. Int. 135, 75–88 (2019)

Candan, E., Ahlatci, H., H. Çı̈menoğlu, : Abrasive wear behaviour of Al–SiC composites produced by pressure infiltration technique. Wear 247(2), 133–138 (2001)

Kumar, S., et al.: Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear 265(1–2), 134–142 (2008)

Kala, H., Mer, K., Kumar, S.: A review on mechanical and tribological behaviors of stir cast aluminum matrix composites. Procedia Mater. Sci. 6, 1951–1960 (2014)

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. 2019R1A2C4070158).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, J., Ahn, M., Han, S. et al. Enhanced Frictional Properties of NiO-Based Nanocomposites with the Addition of GDC. Tribol Lett 69, 71 (2021). https://doi.org/10.1007/s11249-021-01449-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-021-01449-3