Abstract

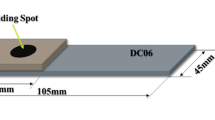

Aluminum alloy 6061 was welded with zinc coated low carbon steel by cold metal transfer (CMT). The microstructure composition, morphology and growth process of the welding joint and the HAZ were researched. The weld area on the side of the galvanized steel sheet mainly contains Fe2Al5. And on the side of the aluminum alloy substrate, it is mainly filled with a needle-like FeAl3. At the same time, Al8Fe2Si is formed at the edge of FeAl3. The zinc-rich region on the side of the aluminum alloy mainly contains an aluminum-zinc solid solution and an aluminum-zinc co-crystal, and the current size had no significant effect on the type and morphology of the compounds produced in the interface layer.

Similar content being viewed by others

References

Patterson E E, Hovanski Y, Field D P. Microstructural Characterization of Friction Stir Welded Aluminum-Steel Joints[J]. Metallurgical & Materials Transactions A, 2016, 47(6): 2815–2829

Taban E, Gould J E, Lippold J C. Dissimilar Friction Welding of 6061-T6 Aluminum and Steel Properties and Microstructural Characterization[J]. Materials & Design, 2010: 2 305–2 311

Elrefaey A, Ross N G. Microstructure and Mechanical Properties of Cold Metal Transfer Welding Similar and Dissimilar Aluminum Alloys[J]. Acta Metallurgica Sinica (English Letters), 2015, 28(6): 715–724

Kovacscoskun T, Volgyi B, Sikarinagl I. Investigation of Aluminum-steel Joint Formed by Explosion Welding[J]. Journal of Physics: Conference Series, 2015, 602: 012 026

Zhang H T, Liu J K. Microstructure Characteristics and Mechanical Property of Aluminum Alloy/stainless Steel Lap Joints Fabricated by MIG Welding-brazing Process[J]. Materials Science and Engineering A, 2011, 528: 6179–6185

Zhang G F, Su W, Zhang J X, et al. Friction Stir Brazing: a Novel Process for Fabricating Al/Steel Layered Composite and For Dissimilar Joining of Al to Steel[J]. Metallurgical and Materials Transactions A, 2011, 42: 2850–2861

Kovacscoskun T, Volgyi B, Sikarinagl I. Investigation of Aluminum-steel Joint Formed by Explosion Welding[J]. Journal of Physics: Conference Series, 2015, 602: 012 026

Gang Z, Chen M J, Yu S, et al. Analysis and Modeling of the Growth of Intermetallic Compounds in Aluminum-steel Joints[J]. Rsc Advances, 2017, 7(60): 37797–37805

Dong H, Hu W, Duan Y, et al. Dissimilar Metal Joining of Aluminum Alloy to Galvanized Steel With Al-Si, Al-Cu, Al-Si-Cu and Zn-Al Filler Wires[J]. Journal of Materials Processing Technology, 2012, 212(2): 458–464

Czechowski M. Stress Corrosion Cracking of Explosion Welded Steel-Aluminum Joints[J]. Materials & Corrosion, 2015, 55(6): 464–467

Dong H, Yang L, Dong C, et al. Arc Joining of Aluminum Alloy to Stainless Steel with Flux-cored Zn-based Filler Metal[J]. Materials Science and Engineering A, 2010, 527(26): 7151–7154

Dong H, Yang L, Dong C, et al. Improving Arc Joining of Al to Steel and Al to Stainless Steel[J]. Materials Science and Engineering A, 2012, 534: 424–435

Dong H, Liao C, Yang L, et al. Effects of Post-weld Heat Treatment on Dissimilar Metal Joint Between Aluminum Alloy and Stainless Steel[J]. Materials Science and Engineering A, 2012, 550: 423–428

Zhu Z, Wan Z, Li Y. Microstructure and Mechanical Properties of Aluminum Alloy/stainless Steel Butt Joint Using Laser-MIG Hybrid Welding-brazing Method[J]. International Journal of Modern Physics B, 2017, 31(16–19): 1 744 035

D R, Achar J, Ruge S. Metallurgical and Mechanical Investigations of Aluminum-steel Fusion Welds[J]. Aluminum, 1980, 56(6): 391–397

Ramachandran K K, Murugan N, Shashi K S. Friction Stir Welding of Aluminum Alloy AA5052 and HSLA Steel: Mechanical and Microstructural Characterization of Dissimilar Friction Stir Welded Butt Joints[J]. Welding Journal, 2015, 94(9): 291–300

Song J L, Lin S B, Yang C L. Spreading Behavior and Microstructure Characteristics of Dissimilar Metals TIG Welding-brazing of Aluminum Alloy to Stainless Steel[J]. Materials Science and Engineering A, 2009, 509: 31–40

Dong H G, Yang L Q, Dong C. Arc Joining of Aluminum Alloy to Stainless Steel With Flux-cored Zn-based Filler Metal[J]. Materials Science and Engineering A, 2010, 527: 7151–7154

Chang Q, Sun D, Gu X. Microstructures and Mechanical Properties of Metal Inert-gas Arc Welded Joints of Aluminum Alloy and Ultrahigh Strength Steel Using Al-Mg and Al-Cu Fillers[J]. Journal of Materials Research, 2017, 32(3): 666–676

Fereiduni E, Movahedi M, Kokabi A H. Aluminum/steel Joints Made by an Alternative Friction Stir Spot Welding Process[J]. Journal of Materials Processing Tech., 2015, 224: 1–10

López E A T, Ramirez A J. Effect of Process Parameters in Obtaining Aluminium-steel Joints and Their Microstructure by Friction Stir Welding (FSW)[J]. Welding International, 2015, 29(9): 689–697

Naumov A, Mertin C, Korte F. On the Growth of Intermetallic Phases by Heat Treatment of Friction Stir Welded Aluminum Steel Joints[J]. Production Engineering, 2017, 11(2): 175–182

Sridharan N, Wolcott P, Dapino M. Microstructure and Mechanical Property Characterisation of Aluminium-steel Joints Fabricated Using Ultrasonic Additive Manufacturing[J]. Science & Technology of Welding & Joining, 2016, 22(5): 1–8

Sridharan N, Wolcott P, Dapino M. Microstructure and Mechanical Property Characterisation of Aluminium-steel Joints Fabricated Using Ultrasonic Additive Manufacturing[J]. Science & Technology of Welding & Joining, 2016, 22(5): 1–8

Su Y, Hua X, Wu Y. Effect of Input Current Modes on Intermetallic Layer and Mechanical Property of Aluminum-steel Lap Joint Obtained by Gas Metal Arc Welding[J]. Materials Science & Engineering A Structural Materials Properties Microstructure & Processing, 2013, 578(31): 340–345

Yi Z, Li F, Guo G. Effects of Different Powders on the Micro-gap Laser Welding-brazing of an Aluminium-steel Butt Joint Using a Coaxial Feeding Method[J]. Materials & Design, 2016, 109: 10–18

Yi Z, Guo G, Li F. The Interface Control of Butt Joints in Laser Braze Welding of Aluminium-steel With Coaxial Powder Feeding[J]. Journal of Materials Processing Technology, 2017, 246: 313–320

Yu S, Jie L, Gang Z, et al. Corrosion Behavior of Aluminum-Steel Weld-Brazing Joint[J]. Journal of Materials Engineering & Performance, 2016, 25(5): 1916–1923

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by National Natural Science Foundation of China (No. 51905333), Shanghai Sailing Program (No. 19YF1418100), Shanghai Science and Technology Committee Innovation Grant (Nos. 17JC1400600, 17JC1400601, 19511106400 and 19511106402), Shanghai Local Colleges and Universities Capacity Building Special Plan Project (No. 19030501300)

Rights and permissions

About this article

Cite this article

Zhang, Q., Zhang, P., Yu, Z. et al. Microstructure and Properties of an Al 6061/Galvanized Plate Fabricated by CMT Welding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 937–945 (2020). https://doi.org/10.1007/s11595-020-2340-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2340-3