Abstract

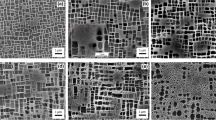

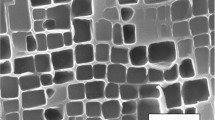

Ni-based single crystalline superalloys are used for high-pressure parts of aero-engines due to their superior mechanical properties and very good oxidation resistance at high temperature. However, shocks or unexpected mismatch in thermal contraction between molds and castings can occur during casting process and subsequent heat treatments, inducing plastic deformation of the alloy at low temperature. To mimic such events, a tensile plastic deformation is applied at room temperature on solutioned AM1 specimens and followed by standard aging heat treatments. Faster growth of the γ′ precipitates inside plastically deformed bands is obtained after full heat treatment with no lattice rotation or recrystallization. It has however been evidenced that the applied deformation has a detrimental impact on the creep properties, especially at high temperature (above 950 °C). It partly results from a highly localized failure process along former slip bands in which recrystallization is observed. The evolution of the microstructure during creep tests of prior deformed and nondeformed specimens has been thoroughly investigated to better identify under which conditions recrystallization occurs inside the bands during a creep test and by which mechanism.

Similar content being viewed by others

References

T.M. Pollock and S. Tin: J. Propul. Power, 2006, vol. 22, pp. 361-374.

R.C. Reed: The Superalloys - Fundamentals and Applications, 1st ed., Cambridge University Press, Cambridge, 2006, pp. 121-211.

P. Caron and T. Khan: Mater. Sci. Eng., 1983, vol. 61, pp. 173-194.

P. Caron and T. Khan: 8th International Conference on the Strength of Metals and Alloys, 1988.

P. Caron, P.J. Henderson, T. Khan, and M. McLean: Scripta Metall. Mater., 1986, vol. 20, pp. 875-880.

P. Caron, Y. Ohta, Y.G. Nakagawa, and T. Khan: in Superalloys 1988 Proc. of the Minerals, Metals and Materials Society, Warrendale, 1988, pp. 215–24.

S. Pierret, T. Etter, A. Evans, and H. Van Swygenhoven: Acta Mater., 2013, vol. 61, pp. 1478-1488.

H. N. Mathur, C. Panwisawas, C. N. Jones, R. C. Reed, C. M.F. Rae and D. Phil: Acta Mater., 2017, vol. 129, pp. 112-123.

R. Bürgel, P. D. Portella and J. Preuhs: Superalloys 2000, TMS, 2000, pp. 229–38.

X.-M. Chen, Y. C. Lin, D. X. Wen, J. L. Zhang and M. He: Mater. Des., 2014, vol. 57, pp. 568-577.

D. Cox, B. Roebuck, C. M. F. Rae and R. C. Reed: Mater. Sci. Tech., 2003, vol. 19, pp. 440-446.

R. D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen and A.D. Rollett: Mat. Sci. Eng. A, 1997, vol. 238, pp. 219-274.

L. Zhonglin, X. Jichun, X. Qingyan, L. Jiarong and L. Baicheng: J. Mater. Process. Tech., 2015, vol. 217, pp. 1-12.

C. Panwisawas, H. Mathur, J.-C. Gebelin, D.C. Putman, P. Withey, N. Warnken, C.M.F. Rae and R.C. Reed: Superalloys 2012: TMS, 2012, pp. 547–56.

Z. Li, Q. Xu and B. Liu: J. Alloy Compd., 2016, vol. 672, pp. 457-469.

Z. Li, X. Fan, Q. Xu and B. Liu: Mater. Lett., 2015, vol. 160, pp. 318-322.

B. G. Choi, C. Y. Jo, H. U. Hong, I. S. Kim, S. M. Seo, and H. M. Kim: Trans. Nonferrous Met. Soc. China, 2011, vol. 21, pp. 1291-1296.

L. Tian, C. Xu and C. Ma: Mater. Charact., 2017, vol. 127, pp. 116-120.

M. Sakaguchi and M. Okazaki: Mat. Sci. Eng. A, 2018, vol. 710, pp.121-128.

J. H. Davidson, A. Fredholm, T. Khan and J.-M. Théret: Patent FR 2557598 / US 4693280, 1986.

J. Cormier, M. Jouiad, F. Hamon, P. Villechaise and X. Milhet: Philos. Mag. Lett., 2010, vol. 90, pp. 611-620.

M. Bensch, C.H. Konrad, E. Fleischmann, C.M.F. Rae and U. Glatzel: Mater. Sci. Eng. A, 2013, vol. 577, pp. 179-188.

F. Riallant, J. Cormier, A. Longuet, X. Milhet and J. Mendez: Met. Mat. Trans. A, 2014, vol. 45A, pp. 351-360.

F. Mauget, F. Hamon, M. Morisset, J. Cormier, F. Riallant, and J. Mendez: Int. J. Fatigue, 2017, vol. 99, pp. 225-34.

V. Caccuri, J. Cormier and R. Desmorat: Mater. Des., 2017, vol. 131, pp. 487-497.

K. Thompson, D. Lawrence, D. J. Larson, J. D. Olson, T. F. Kelly and B. Gorman: Ultramicroscopy, 2007, vol. 107, pp. 131-139.

M.-A. Charpagne, P. Vennegues, T. Billot, J.-M. Franchet and N. Bozzolo: J. Microsc., 2016, vol. 263, pp. 106-112.

M. Sakaguchi, M. Ike, and M. Okazaki: Mat. Sci. Eng. A, 2012, vol. 534, pp. 253-259.

L. Dirand, J. Cormier, A. Jacques, J.-P. Chateau-Cornu, T. Schenk, O. Ferry and P. Bastie: Mater. Charact., 2013, vol. 77, pp. 32-46.

A. Epishin, T. Link and G. Nolze: J. Microsc., 2007, vol. 228, pp. 110-117.

J. Cormier: Superalloys 2016, TMS, 2016, pp. 385–94.

P. Caron, C. Ramusat and F. Diologent: Superalloys. 2008, TMS, 2008, pp. 159–67.

G.L. Drew, R.C. Reed, K. Kakehi and C.M.F. Rae: Superalloys 2004, TMS, 2004, pp. 127–36.

M.-A. Charpagne, T. Billot, J.-M. Franchet and N. Bozzolo, J. Alloys and Compd., 2016, vol. 688, pp. 685-694.

M.-A. Charpagne, J.-M. Franchet and N. Bozzolo: Mater. Des., 2018, vol. 144, pp. 353-360.

J.J. Moverare, S. Johansson and R.C. Reed: Acta Mater., 2009, vol. 57, pp. 2266-2276.

M. Segersäll, P. Kontis, S. Pedrazzini, P.A. Bagot, M.P. Moody, J.J. Moverare and R.C. Reed: Acta Mater., 2015, vol. 95, pp. 456-467.

R.C. Reed, D.C. Cox and C.M.F. Rae: Mat. Sci. Eng. A, 2007, vol. 448, pp. 88-96.

G. Malzer, R.W. Hayes, T. Mack and G. Eggeler, Met. Mat. Trans. A, 2007, vol. 38A, pp. 314-327.

J.-B. le Graverend, J. Adrien and J. Cormier: Mat. Sci. Eng. A, 2017, vol. 695, pp. 367-378.

A. Cervellon, J. Cormier, F. Mauget and Z. Hervier : Int. J. Fatigue, 2017, vol. 104, pp. 251-262.

P. Kontis, Z. Li, D.M. Collins, J. Cormier, D. Raabe and B. Gault: Scr. Mater., 2018, vol. 148, pp. 76-80.

P. Kontis, D.M. Collins, A.J. Wilkinson, R.C. Reed, D. Raabe and B. Gault: Scr. Mater., 2018, vol. 147, pp. 59-63.

M.C. Pandey, A.K. Mukherjee and D.M.R. Taplin: Metall. Trans. A, 1984, vol. 15, pp. 1437-1441.

Y.H. Zhang and D.M. Knowles: Mater. Sci. Technol., 2002, vol. 18, pp. 917-923.

K.C. Antony and G.W. Goward, Superalloys 1988, TMS, 1988, pp. 745–54.

B.F. Dyson and D.E. Henn, The effect of room temperature pre‐strain on grain boundary cavitation in Nimonic 80A, Journal of Microscopy 1973, vol. 97, pp. 165-170.

B.F. Dyson and M.J. Rodgers, Prestrain, cavitation, and creep ductility, Metal Science 1974, vol. 8, pp. 261-266.

M. Feller-Kniepmeier, T. Link, I. Poschmann, G. Scheunemann-Frerker, C. Schulze: Acta Mater., 1996, vol. 44, pp. 2397–2407.

H. Mughrabi: Mater. Sci. Technol., 2009, vol. 25, pp. 191-204.

T.M. Pollock and A.S. Argon: Acta Metall. Mater., 1994, vol. 42, pp. 1859-1874.

R.C. Reed, D.C. Cox and C.M.F. Rae: Mater. Sci. Technol., 2007. 23: p. 893-902.

M. Kamaraj: Sadhana, 2003, vol. 28, pp. 115-128.

L. Zhuo, T. Xu, F. Wang, J. Xiong and J. Zhu: Mater. Lett., 2015, vol. 148, pp. 159-162.

B. Reppich: Acta Metall., 1982, vol. 30(1), pp. 87-94.

B. Reppich, W. Kühlein, G. Meyer, P. Puppel, M. Schulz and G. Schumann: Mater. Sci. Eng., 1986, vol. 83, pp. 45-63.

Acknowledgments

The authors are grateful to Professor Dierk Raabe and Dr. Baptiste Gault (both from Max-Planck-Institut für Eisenforschung GmbH, Düsseldorf, Germany) for the interpretation of APT results and fruitful scientific discussions. The authors thank Dr. Susanne Steuer, formerly at the Institut Pprime and UCSB and now at Thyssenkrupp for technical assistance on creep testing. The authors also gratefully acknowledge the fruitful scientific discussions on recrystallization with Dr. Nicolas Leriche (from Safran Aircraft Engines, Gennevilliers, France).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 9, 2018.

Rights and permissions

About this article

Cite this article

Hamadi, S., Hamon, F., Delautre, J. et al. Consequences of a Room-Temperature Plastic Deformation During Processing on Creep Durability of a Ni-Based SX Superalloy. Metall Mater Trans A 49, 4246–4261 (2018). https://doi.org/10.1007/s11661-018-4748-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4748-3