Abstract

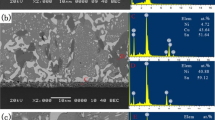

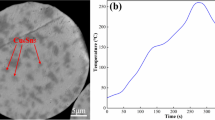

In this study, a rapid solder melting process has been examined through a self-propagating exothermic reaction using Al/Ni nanofoil as a localized heat source. Four kinds of tin-based solder preforms were partly melted under this process, and the thicknesses of the fusion zone in solder preforms around the Al/Ni nanofoil were experimentally analyzed. The microstructure and morphology of the fusion zone in different kinds of solder preforms were studied by metallographic analysis. In Sn42Bi58 solder, the mean grain size of Bi-rich phases in the fusion zone was finer than the original structure, and decreased from ~ 2.7 μm to ~ 0.8 μm away from the Al/Ni nanofoil. Similar trends of mean size of grains in the fusion zone were also found in the Sn, Sn-3 wt.%Ag-0.5 wt.%Cu(SAC), and SnPb solder preforms. The widths of the fusion zone in the Sn, SAC, SnPb, and SnBi solder preforms were 150 μm, 173 μm, 188 μm, and 233 μm, respectively. In addition, the nano-hardness and distribution in the fusion zones were evaluated. The results show that the value of nanohardness increased along with the decrease of distance from Al/Ni nanofoil. The average hardness and the lower and upper bounds of Sn, SnPb, SAC, and SnBi solder in the fusion zone are 0.260 (−0.045, +0.039) GPa, 0.246 (−0.059, +0.114) GPa, 0.260 (−0.014, +0.070) GPa, and 0.404 (−0.072, +0.134) GPa, respectively. The statistical significance of solder hardness is related to its alloy component, element content, and microstructure.

Similar content being viewed by others

References

Y.-C. Lin, M. Baum, M. Haubold, J. Fromel, M. Wiemer, T. Gessner, and M. Esashi, in International Solid-State Sensors, Actuators and Microsystems Conference (2009), pp. 244–247.

X. Qiu, J. Zhu, J. Oiler, C. Yu, Z. Wang, and H. Yu, J. Phys. D Appl. Phys. 42, 18 (2009).

J. Wang, E. Besnoin, O.M. Knio, and T.P. Weihs, Appl. Phys. Lett. 83, 19 (2003).

Yoosuf N. Picard and Steven M. Yalisove, Appl. Phys. Lett. 88, 14 (2006).

J.-H. Peng, J. Binner, and S. Bradshaw, Mater. Sci. Technol. 18, 12 (2002).

E. Grigoryan, N.G. Elistratov, D.Yu. Kovalev, A.G. Merzhanov, A.N. Nosyrev, V.I. Ponomarev, A.S. Rogachev, V.I. Khvesyuk, and P.A. Tsygankov, Dokl. Phys. Chem. 381, 1 (2001).

D.P. Adams, M.A. Rodriguez, J.P. McDonald, M.M. Bai, E. Jones Jr, L. Brewer, and J.J. Moore, J. Appl. Phys. 106, 9 (2009).

A.J. Gavens, D. Van Heerden, A.B. Mann, M.E. Reiss, and T.P. Weihs, J. Appl. Phys. 87, 3 (2000).

U. Gösele, H. Stenzel, T. Martini, J. Steinkirchner, D. Conrad, and K. Scheerschmidt, Appl. Phys. Lett. 67, 24 (1995).

A.J. Swiston Jr., T.C. Hufnagel, and T.P. Weihs, Scr. Mater. 48, 12 (2003).

A. Duckham, S.J. Spey, J. Wang, M.E. Reiss, T.P. Weihs, E. Besnoin, and O.M. Knio, J. Appl. Phys. 96, 4 (2004).

J. Braeuer, J. Besser, M. Wiemer, and T. Gessner, in International Solid-State Sensors, Actuators and Microsystems Conference (2011), pp. 1332–1335.

J. Zhang, F.-S. Wu, J. Zou, B. An, and H. Liu, in International Conference on Electronic Packaging Technology & High Density Packaging (2009), pp. 838–842.

G.D. Theodossiadis and M.F. Zaeh, Prod. Eng. 11, 4–5 (2017).

Z. Zhou, L. Mo, H. Liu, Y.C. Chan, and F. Wu, J. Electron. Mater. 47, 12 (2018).

J. Wang, E. Besnoin, A. Duckham, S.J. Spey, M.E. Reiss, O.M. Knio, and T.P. Weihs, J. Appl. Phys. 95, 1 (2004).

W. Zhu, F. Wu, B. Wang, E. Hou, P. Wang, C. Liu, and W. Xia, Microelectron. Eng. 128, 24 (2014).

J. Braeuer, J. Besser, M. Wiemer, and T. Gessner, Sens. Actuators A Phys. 188, 212 (2012).

B. Boettge, J. Braeuer, M. Wiemer, M. Petzold, J. Bagdahn, and T. Gessner, J. Micromech. Microeng. 20, 064018 (2010).

R. Grieseler, T. Welker, J. Müller, and P. Schaaf, Phys. Status Solidi A 209, 512 (2012).

C. Pascal, R. Marin-Ayral, and J. Tedenac, J. Alloys Compd. 337, 221 (2002).

W.R. Osório, J.E. Spinelli, C.R.M. Afonso, L.C. Peixoto, and A. Garcia, Electrochim. Acta 56, 24 (2011).

U. Böyük and N. Maraşlı, Mater. Chem. Phys. 119, 3 (2010).

G. Wei and L. Wang, in International Conference on Electronic Packaging Technology and High Density Packaging (2012), pp. 453–456.

R.M. Shalaby, Cryst. Res. Technol. 45, 4 (2010).

F. Ochoa, J.J. Williams, and N. Chawla, JOM 55, 6 (2003).

B.J. Briscoe, L. Fiori, and E. Pelillo, J. Phys. D Appl. Phys. 31, 19 (1998).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

H. Gao, Y. Huang, and W. Nix, Nat. Wiss. 86, 507 (1999).

Y.W. Bao, W. Wang, and Y.C. Zhou, Acta Mater. 52, 18 (2004).

Acknowledgments

The authors acknowledge the financial support provided by the National Natural Science Foundation of China (NSFC No. 61574068, NSFC No. 61261160498), as well as two research grants on “quasi-ambient bonding (QAB)” (Ref: EP/R032203/1) and “heterogeneous integration (HI)” (Ref: EP/R004501/1) funded by EPSRC of the United Kingdom. The authors also acknowledge the support provided by the China Association for Science and Technology (No. 2018CASTQNJL55). In addition, the authors thank Huazhong University of Science and Technology Analytical and Testing Center, Hubei University of Technology Analytical and Testing Center, State Key Laboratory of Material Processing and Die & Mould Technology for SEM analysis and mechanical properties testing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Z., Zhang, A., Guan, X. et al. Microstructural and Micromechanical Characteristics of Tin-Based Solders Under Self-Propagating Exothermic Reaction Heating. J. Electron. Mater. 49, 6214–6222 (2020). https://doi.org/10.1007/s11664-020-08363-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08363-9