Abstract

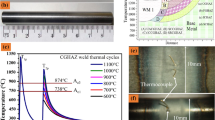

Microstructure refinement strategies in simulated carburized microstructures were evaluated because of their potential for improving the fatigue performance of case-carburized components. Commercial 52100 steel was used to simulate the high-carbon content in the case. Specimens were subjected to various thermal treatments in a quenching dilatometer. Reheating cycles to austenitizing temperatures were evaluated with respect to both prior austenite grain size (PAGS) and associated martensite and retained austenite (RA) refinement. Quantitative stereological measurements were performed to evaluate the microgeometry of plate martensite and the size distribution of RA regions. Decreasing the reheating temperature resulted in finer PAGS, and multiple reheating cycles resulted in a narrower PAGS distribution. Refinement in PAGS led to a reduction in martensite plate size and finer distribution of RA. Additionally, interrupted quenching below martensite start (MS) temperature was evaluated. This processing route results in a refinement of martensite plates and more stable RA. The stabilization of austenite may be mechanical or chemical in nature, owing to the deformation of austenite during primary transformation, or due to partitioning of carbon into austenite similar to quenching and partitioning steels.

Similar content being viewed by others

References

H. Mohrbacher, Metallurgical Concepts for Optimized Processing and Properties of Carburizing Steel, Adv. Manuf., 2016, 4, p 105–114. https://doi.org/10.1007/s40436-016-0142-9

G. Krauss, Fatigue and Fracture, in ASM Handbook.Vol.19, ASM International, pp. 680–690, (1996). https://doi.org/10.31399/asm.hb.v19.9781627081931

J.P. Wise and D.K. Matlock, Bending Fatigue of Carburized Steels: A statistical Analysis of Process and Microstructural Parameters, SAE Trans., 2000, 109, p 182–191. https://doi.org/10.4271/2000-01-0611

C.A. Apple and G. Krauss, Microcracking and Fatigue in a Carburized Steel, Metall. Trans., 1973, 4(5), p 1195–1200. https://doi.org/10.1007/BF02644511

S.M.C. Van Bohemen and J. Sietsma, Martensite Formation in Partially and Fully Austenitic Plain Carbon Steels, Metall. Mater. Trans. A, 2009, 40(5), p 1059–1068. https://doi.org/10.1007/s11661-009-9796-2

S.M.C. van Bohemen and J. Sietsma, Kinetics of Martensite Formation in Plain Carbon Steels: Critical Assessment of Possible Influence of Austenite Grain Boundaries and Autocatalysis, Mater. Sci. Technol., 2014, 30(9), p 1024–1033. https://doi.org/10.1179/1743284714Y.0000000532

A.R. Entwisle, The Kinetics of Martensite Formation in Steel, Metall. Trans., 1971, 2(9), p 2395–2407. https://doi.org/10.1007/BF02814877

C.H. Shih, B.L. Averbach, and M. Cohen, Some Characteristics of the Isothermal Martensitic Transformation, JOM, 1955, 7(1), p 183–187. https://doi.org/10.1007/BF03377476

G.B. Olson and M. Cohen, A General Mechanism of Martensitic Nucleation: Part I. FCC → HCP and Other Martensitic Transformations, Metall. Trans. A, 1976, 7, p 1897–1904. https://doi.org/10.1007/bf02659822

G.B. Olson and M. Cohen, A General Mechanism of Martensitic Nucleation: Part II. FCC → BCC and other Martensitic Transformations, Metall. Trans. A, 1976, 7, p 1905–1914. https://doi.org/10.1007/bf02659823

S. Karewar, J. Sietsma, and M.J. Santofimia, Effect of Pre-existing Defects in the Parent fcc Phase on Atomistic Mechanisms During the Martensitic Transformation in pure Fe: a Molecular dynamics Study, Acta Mater., 2018, 142, p 71–81. https://doi.org/10.1016/j.actamat.2017.09.049

C. Celada-Casero, J. Sietsma, and M.J. Santofimia, The Role of the Austenite Grain Size in the Martensitic Transformation in Low Carbon Steels, Mater. Des., 2019, 167, p 107625. https://doi.org/10.1016/j.matdes.2019.107625

D.V. Edmonds, K. He, F.C. Rizzo, B.C. De Cooman, D.K. Matlock, and J.G. Speer, Quenching and Partitioning Martensite—A Novel Steel Heat Treatment, Mat. Sci. Eng. A, 2006, 438–440, p 25–34. https://doi.org/10.1016/j.msea.2006.02.133

P.H. Chang, P.G. Winchell, and G.L. Liedl, Quantitative Geometric Characterization of High Carbon Martensite, Metall. Trans. A, 1983, 14(1), p 163–173. https://doi.org/10.1007/BF02651612

P.R. Rios and J.R.C. Guimarães, Microstructural Path Analysis of Athermal Martensite, Scr. Mater., 2007, 57(12), p 1105–1108. https://doi.org/10.1016/J.SCRIPTAMAT.2007.08.019

J.R.C. Guimarães and P.R. Rios, Spatial Aspects of Martensite, Metall. Mater. Trans. A, 2012, 43(7), p 2218–2224. https://doi.org/10.1007/s11661-012-1102-z

J.R.C. Guimarães and J.C. Gomes, A Metallographic Study of the Influence of the Austenite Grain Size on Martensite Kinetics, Acta Metall., 1978, 26(10), p 1591–1596. https://doi.org/10.1016/0001-6160(78)90068-8

E.E. Underwood, Quantitative Stereology for Microstructural Analysis, Microstructural analysis, Springer, Boston, 1973, p 35–66 https://doi.org/10.1007/978-1-4615-8693-7_3

R.T. DeHoff and F.N. Rhines, Quantitative MIcroscopy, McGraw-Hill, New York, 1968

J. Takahashi and H. Suito, Evaluation of the Accuracy of the Three-dimensional Size Distribution Estimated from the Schwartz-Saltykov Method, Metall. Mater. Trans. A, 2003, 34, p 171–181. https://doi.org/10.1007/s11661-003-0218-6

J.C. Fisher, J.H. Hollomon, and D. Turnbull, Kinetics of the Austenite → Martensite Transformation, JOM, 1949, 1(10), p 691–700

J.R.C. Guimarães, Athermal Martensite: Genesis of Microstructure and Transformation Curves, Mater. Sci. Eng., A, 2008, 476(1–2), p 106–111. https://doi.org/10.1016/j.msea.2007.04.068

P.H. Chang, H. Rubin, P.G. Winchell, and G.L. Liedl, The Determination of Size Distribution of Martensite Plates by Kernel Estimation, Scr. Metall., 1982, 16(5), p 531–536. https://doi.org/10.1016/0036-9748(82)90264-2

I.B. Timokhina, P.D. Hodgson, and E.V. Pereloma, Effect of Microstructure on the Stability of Retained Austenite in Transformation-induced-plasticity Steels, Metall. Mater. Trans. A, 2004, 35(8), p 2331–2341. https://doi.org/10.1007/s11661-006-0213-9

J.H. Ryu, D.-I. Kim, H.S. Kim, H.K.D.H. Bhadeshia, and D.-W. Suh, Strain Partitioning and Mechanical Stability of Retained Austenite, Scr. Mater., 2010, 63(3), p 297–299. https://doi.org/10.1016/J.SCRIPTAMAT.2010.04.020

S. Zhang and K.O. Findley, Quantitative Assessment of the Effects of Microstructure on the Stability of Retained Austenite in TRIP Steels, Acta Mater., 2013, 61(6), p 1895–1903. https://doi.org/10.1016/j.actamat.2012.12.010

S. Chatterjee and H.K.D.H. Bhadeshia, Transformation Induced Plasticity Assisted Steels: Stress or Strain Affected Martensitic Transformation, Mater. Sci. Technol., 2007, 23(9), p 1101–1104

E.J. Seo, L. Cho, Y. Estrin, and B.C. De Cooman, Microstructure-Mechanical Properties Relationships for Quenching and Partitioning (Q&P) Processed Steel, Acta Mater., 2016, 113, p 124–139. https://doi.org/10.1016/j.actamat.2016.04.048

T. Man, T. Ohmura, and Y. Tomota, Mechanical Behavior of Individual Retained Austenite Grains in High Carbon Quenched-tempered Steel, ISIJ Int., 2019, 59(3), p 559–566. https://doi.org/10.2355/isijinternational.ISIJINT-2018-620

Acknowledgments

This research project is being supported by NSF-CMMI award number 1728007. The authors also gratefully acknowledge the support of the sponsors of Advanced Steel Processing and Products Research Center at Colorado School of Mines, especially TimkenSteel, for providing the raw material for this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Agnani, M., DeNonno, O.L., Findley, K.O. et al. Quantitative Analysis of Microstructural Refinement in Simulated Carburized Microstructures. J. of Materi Eng and Perform 29, 3551–3559 (2020). https://doi.org/10.1007/s11665-020-04714-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04714-z