Abstract

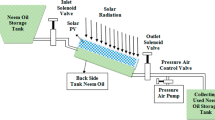

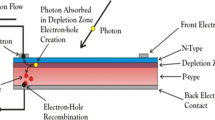

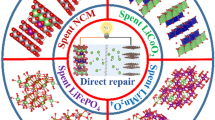

This work is focused on optimizing the properties of encapsulant for low-concentration photovoltaic (LCPV) modules leading to improved electrical power and module life. Thermal conductivity (TC), long-term shear modulus (G∞) and coefficient of thermal expansion (CTE) of backside encapsulant are optimized using finite element (FE) simulations on LCPV module. It is found that as compared with ethylene-vinyl acetate (EVA), increased TC can improve electrical power, while decreased CTE and G∞ can improve module life. Polymer composites with improved properties are computationally designed using in-house built design codes. Thermoplastic polyurethane (TPU) and ceramic fillers (particularly Al2O3 and AlN) with designated particle’s geometry and volume fraction are predicted as the most suitable constituents. The selected compositions are processed, and their properties are measured accordingly. The measured properties are used in the parent FE simulations to predict the expected values of electrical power and module life to confirm the feasibility of replacing EVA with TPU-composites. The proposed composite has a combination of high TC and tailored CTE and G∞, which lowers the cell temperature and thermal strains enhancing the electrical power by 4.38% and the module life by 93%, respectively.

Similar content being viewed by others

Abbreviations

- LCPV:

-

Low-concentration photovoltaic

- HCPV:

-

High concentration photovoltaic

- TPU:

-

Thermoplastic polyurethane

- PDMS:

-

Polydimethylsiloxane

- EVA:

-

Ethylene-vinyl acetate

- PVB:

-

Polyvinyl butyral

- Al2O3 :

-

Alumina

- AlN:

-

Aluminum nitride

- k = TC:

-

Thermal conductivity

- α = CTE:

-

Coefficient of thermal expansion = α

- G ∞ :

-

Long-term shear modulus

- Ρ :

-

Density

- C p :

-

Specific heat at constant pressure

- T :

-

Absolute temperature

- Q :

-

Heat flux

- Q :

-

Extra heat source = 0 in this study

- {s}:

-

Stress vector

- F v :

-

Body force per unit deformed volume

- [C]:

-

Stiffness tensor

- {ε el}:

-

Mechanical strain vector

- {ε}:

-

Total strain vector

- {εth}:

-

Thermal strain vector

- α i :

-

Coefficient of thermal expansion in ith direction

- Tref :

-

The temperature of zero strain and stress

- E :

-

Young’s modulus

- ν :

-

Poisson’s ratio

- σ 0 :

-

Yield strength

- M :

-

Tangent modulus

- Δε :

-

Strain range

- σ' f :

-

Fatigue strength coefficient = 345 MPa

- σ m :

-

Mean stress

- N f :

-

Number of reversals

- b :

-

Fatigue strength exponent = − 0.05

- ε' f :

-

Fatigue ductility coefficient = 0.3

- c :

-

Fatigue ductility exponent = − 0.6

- n :

-

Surface normal

- q 0 :

-

Amount of energy converted into heat per unit volume

- η pv :

-

Electrical efficiency of the cells

- A module :

-

The top surface area of the PV module

- V module :

-

The volume of the module

- G :

-

Solar irradiance

- H :

-

Heat loss coefficient

- α b :

-

The absorbance of the PV module

- T amb :

-

Ambient temperature

- T s :

-

Surface temperature

- R enc :

-

The thermal resistance of backside encapsulant

- t enc :

-

The thickness of backside encapsulant

- A cell :

-

The contact area between cells and backside encapsulant

- k enc :

-

Thermal conductivity of backside encapsulant

- ITR:

-

Interface thermal resistance

- DMA:

-

Dynamic mechanical analyzer

- G´:

-

Storage modulus

- tanδ :

-

Damping factor

- T g :

-

Glass transition temperature

- α T :

-

Shift function, and log (αT) is called as the horizontal shift factor

- F :

-

Oscillating frequency in DMA testing

- τ i :

-

Relaxation time of ith branch of generalized Maxwell model

- G i :

-

Elastic modulus of ith branch of generalized Maxwell model

- t :

-

Real-time

- Ξ :

-

Pseudo-time

- R(ξ):

-

Relaxation modulus in time domain

- M :

-

Number of viscoelastic branches in generalized Maxwell model

References

S. Europe, “SolarPower Europe’s Global Market Outlook 2018-2022,” 2018, https://www.solarpowereurope.org/wp-content/uploads/2018/09/Global-Market-Outlook-2018-2022.pdf.

M. Khamooshi, H. Salati, F. Egelioglu, A. Hooshyar Faghiri, J. Tarabishi and S. Babadi, A Review of Solar Photovoltaic Concentrators, Int. J. Photoenergy, 2014, 2014, p 1–17. https://doi.org/10.1155/2014/958521

M. Wiesenfarth, I. Anton and A.W. Bett, Challenges in the Design of Concentrator Photovoltaic (CPV) Modules to Achieve Highest Efficiencies, Appl. Phys. Rev., 2018, 5(4), p 041601. https://doi.org/10.1063/1.5046752

D. Du, J. Darkwa and G. Kokogiannakis, Thermal Management Systems for Photovoltaics (PV) Installations: A Critical Review, Sol. Energy, 2013, 97, p 238–254. https://doi.org/10.1016/j.solener.2013.08.018

M.U. Siddiqui and A.F.M. Arif, Electrical, Thermal and Structural Performance of a Cooled PV Module: Transient Analysis Using a Multiphysics Model, Appl. Energy, 2013, 112, p 300–312. https://doi.org/10.1016/j.apenergy.2013.06.030

G. Griffini and S. Turri, Polymeric Materials for Long-Term Durability of Photovoltaic Systems, J. Appl. Polym. Sci., 2016, 2016, p 1–16.

O. Hasan and A.F.M. Arif, Performance and Life Prediction Model for Photovoltaic Modules: Effect of Encapsulant Constitutive Behavior, Sol. Energy Mater. Sol. Cells, 2014, 122, p 75–87. https://doi.org/10.1016/j.solmat.2013.11.016

M.L. Einsla, C.I. Teich, M.T. Bender, J.A. Ottinger, C.L. Jackson, K.B. Laughlin and E.C. Greer, Acrylic/Urethane Hybrid Liquid Encapsulants for Photovoltaic Modules, Sol. Energy Mater. Sol. Cells, 2017, 165(June 2016), p 103–110. https://doi.org/10.1016/j.solmat.2017.02.034

B. Ottersböck, G. Oreski and G. Pinter, Comparison of Different Microclimate Effects on the Aging Behavior of Encapsulation Materials Used in Photovoltaic Modules, Polym. Degrad. Stab., 2017, 138, p 182–191. https://doi.org/10.1016/j.polymdegradstab.2017.03.010

A. Omazic, G. Oreski, M. Halwachs, G.C. Eder, C. Hirschl, L. Neumaier, G. Pinter and M. Erceg, Relation between Degradation of Polymeric Components in Crystalline Silicon PV Module and Climatic Conditions: A Literature Review, Sol. Energy Mater. Sol. Cells, 2019, 192(May 2018), p 123–133. https://doi.org/10.1016/j.solmat.2018.12.027

C. Peike, I. Hädrich, K.-A. Weiß and I. Dürr, Overview of PV Module Encapsulation Materials, Photovoltaics Int., 2013, 19, p 85–92.

E. Tatsi and G. Griffini, Polymeric Materials for Photon Management in Photovoltaics, Sol. Energy Mater. Sol. Cells, 2019, 196(March), p 43–56.

R. Li, X. Lv, J. Yu, X. Wang and P. Huang, Dielectric, Thermally Conductive, and Heat-Resistant Polyimide Composite Film Filled with Silver Nanoparticle-Modified Hexagonal Boron Nitride, High Perform. Polym., 2020, 32, p 1181–1190.

S.S. Akhtar, M.U. Siddiqui, R. Kabeer, A. Hakeem, L. Kareem and A.F. Arif, A Computational and Experimental Study on the Effective Properties of Al2O3-Ni Composites, Int. J. Appl. Ceram. Technol., 2017, 14(4), p 766–778. https://doi.org/10.1111/ijac.12674

C. Chen, J. Wang, X. Chen, X. Yu and Q. Zhang, Improvement of Thermal Conductivities and Mechanical Properties for Polyphthalonitrile Nanocomposites via Incorporating Functionalized H-BN Fillers, High Perform. Polym., 2019, 31(3), p 294–303.

L. Huang, P. Zhu, G. Li, F. Zhou, D. Lu, R. Sun and C. Wong, Spherical and Flake-like BN Filled Epoxy Composites: Morphological Effect on the Thermal Conductivity, Thermo-Mechanical and Dielectric Properties, J. Mater. Sci. Mater. Electron., 2015, 26(6), p 3564–3572. https://doi.org/10.1007/s10854-015-2870-1

M.J. Mochane, T.C. Mokhena, J.S. Sefadi, T.S. Motsoeneng, and A. Mtibe, Recent Advances on Thermal Conductivity of Boron Nitride-Polymer Composites, Handbook of Polymer and Ceramic Nanotechnology, 2019, p 1–16.

S. Li, T. Yang, H. Zou, M. Liang and Y. Chen, Enhancement in Thermal Conductivity and Mechanical Properties via Large-Scale Fabrication of Boron Nitride Nanosheets, High Perform. Polym., 2017, 29(3), p 315–327.

C.P. Wong and R.S. Bollampally, Thermal Conductivity, Elastic Modulus, and Coefficient of Thermal Expansion of Polymer Composites Filled with Ceramic Particles for Electronic Packaging, J. Appl. Polym. Sci., 1999, 74(14), p 3396–3403.

B. Lee, J.Z. Liu, B. Sun, C.Y. Shen and G.C. Dai, Thermally Conductive and Electrically Insulating EVA Composite Encapsulant for Solar Photovoltaic (PV) Cell, Express Polym. Lett., 2008, 2(5), p 357–363.

J. Allan, H. Pinder and Z. Dehouche, Enhancing the Thermal Conductivity of Ethylene-Vinyl Acetate (EVA) in a Photovoltaic Thermal Collector, AIP Adv., 2016, 6, p 1–9.

J. Sebastian, E.T. Thachil, J.J. Mathen, J. Madhavan, P. Thomas, J. Philip, M.S. Jayalakshmy, S. Mahmud and G.P. Joseph, Enhancement in the Electrical and Thermal Properties of Ethylene Vinyl Acetate (EVA) Co-Polymer by Zinc Oxide Nanoparticles, Open J. Compos. Mater., 2015, 5(July), p 79–91.

S.S. Akhtar, K.T. Lemboye, A.F.M. Arif and K.S. Al-Athel, Design and Performance Evaluation of Al2O3-SiC Composite for Direct-Bonded Copper Substrate, J. Mater. Eng. Perform., 2018, 27(11), p 5831–5844. https://doi.org/10.1007/s11665-018-3702-2

K. Raza, S.S. Akhtar, A.F.M. Arif, and A.S. Hakeem, “Design of a Composite Encapsulation for Concentrated Photovoltaic Systems with Improved Performance,” ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), 2019.

K. Raza, S.S. Akhtar, A.F.M. Arif and A.S. Hakeem, Computational Design and Development of High-Performance Polymer-Composites as New Encapsulant Material for Concentrated PV Modules, Sci. Rep., 2020, 10(1), p 5304. https://doi.org/10.1038/s41598-020-62191-9

U. Eitner, S. Kajari-Schröder, M. Köntges and H. Altenbach, Thermal Stress and Strain of Solar Cells in Photovoltaic Modules, Shell-like Structure. H. Altenbach, V.A. Eremeyev Ed., Springer, Berlin, 2011, p 453–468. https://doi.org/10.1007/978-3-642-21855-2_29

H. Watanabe, N. Yamada and M. Okaji, Linear Thermal Expansion Coefficient of Silicon from 293 to 1000 K, Int. J. Thermophys., 2004, 25(1), p 221–236. https://doi.org/10.1023/B:IJOT.0000022336.83719.43

O. Hasan, A.F.M. Arif, and M.U. Siddiqui, “Finite Element Modeling and Analysis of Photovoltaic Modules,” Volume 8: Mechanics of Solids, Structures and Fluids, (Houston, Texas, USA), ASME, 2012, p 495, doi:https://doi.org/10.1115/IMECE2012-89429.

M. Owen-Bellini, P. Hacke, D.C. Miller, M.D. Kempe, S. Spataru, T. Tanahashi, S. Mitterhofer, M. Jankovec and M. Topič, Advancing Reliability Assessments of Photovoltaic Modules and Materials Using Combined-accelerated Stress Testing, Prog. Photovoltaics Res. Appl., 2021, 29(1), p 64–82. https://doi.org/10.1002/pip.3342

A. Ince and G. Glinka, A Modification of Morrow and Smith-Watson-Topper Mean Stress Correction Models, Fatigue Fract. Eng. Mater. Struct., 2011, 34(11), p 854–867.

K. Raza, S.S. Akhtar, A.F.M. Arif, and A.S. Hakeem, “An Improved Predictive Model for Effective Thermal Conductivity of Polymer Composites With Non-Dilute Filler Concentrations,” Volume 12: Advanced Materials: Design, Processing, Characterization, and Applications, American Society of Mechanical Engineers, 2019, https://doi.org/10.1115/IMECE2019-10960.

T. Mori and K. Tanaka, Average Stress in Matrix and Average Elastic Energy of Materials with Misfitting Inclusions, Acta Metall., 1973, 21(5), p 571–574. https://doi.org/10.1016/0001-6160(73)90064-3

S.S. Akhtar, L.T. Kareem, A.F.M. Arif, M.U. Siddiqui and A.S. Hakeem, Development of a Ceramic-Based Composite for Direct Bonded Copper Substrate, Ceram. Int., 2017, 43(6), p 5236–5246. https://doi.org/10.1016/j.ceramint.2017.01.049

B.L. Zhu, J. Wang, H. Zheng, J. Ma, J. Wu and R. Wu, Investigation of Thermal Conductivity and Dielectric Properties of LDPE-Matrix Composites Filled with Hybrid Filler of Hollow Glass Microspheres and Nitride Particles, Compos. Part B Eng., 2015, 69, p 496–506.

J.A. Duffie, W.A. Beckman and W.M. Worek, Design of Photovoltaic Systems, Sol. Eng. Therm. Process, 2013 https://doi.org/10.1115/1.2930068

I. Doghri and L. Tinel, Micromechanical Modeling and Computation of Elasto-Plastic Materials Reinforced with Distributed-Orientation Fibers, Int. J. Plast., 2005, 21(10), p 1919–1940.

K. Raza, M.U. Siddiqui, A.F.M. Arif, S.S. Akhtar and A.S. Hakeem, Design and Development of Thermally Conductive Hybrid Nano-composites in Polysulfone Matrix, Polym. Compos., 2019, 40(4), p 1419–1432. https://doi.org/10.1002/pc.24879

W. Jiajun and Y. Xiao-Su, Effects of Interfacial Thermal Barrier Resistance and Particle Shape and Size on the Thermal Conductivity of AlN/PI Composites, Compos. Sci. Technol., 2004, 64(10–11), p 1623–1628.

G. Bódai and T. Goda, Parameter Identification Methods for Generalized Maxwell Models: Engineering Approach for Small-Strain Viscoelasticity, Mater. Sci. Forum, 2010, 659, p 379–384.

G.C. Papanicolaou and S.P. Zaoutsos, “Viscoelastic Constitutive Modeling of Creep and Stress Relaxation in Polymers and Polymer Matrix Composites,” Creep and Fatigue in Polymer Matrix Composites, 2nd ed., Elsevier Ltd., 2010, https://doi.org/10.1533/9780857090430.1.3.

Acknowledgments

The authors would like to acknowledge the support and resources made available at the Mechanical Engineering Department and Center of Excellence in Nanotechnology, KFUPM to complete this work. Special thanks to Dr. Tareq Manzoor from the “Energy Research Center, COMSATS University Islamabad, Lahore Campus, Pakistan” for reviewing this work and providing his useful feedback.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akhtar, S.S., Raza, K., Arif, A.F.M. et al. Simulation Led Performance Evaluation and Design of Polymer Composite for Encapsulation of Low-Concentration Photovoltaic Modules. J. of Materi Eng and Perform 30, 8242–8256 (2021). https://doi.org/10.1007/s11665-021-05999-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05999-4