Abstract

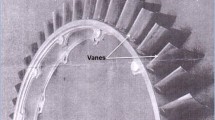

An aircraft crashed shortly after take-off. Initial investigation determined that the crash occurred due to an engine failure with an accumulated 4955 flight hours and 4018 take-off/landing cycles. Engine teardown revealed that several turbine blades on the second-stage power turbine (PT) had failed due to fatigue in the airfoil. This article presents an uncommon crack initiation mode by liquid metal corrosion. It was initially postulated that the turbine blades of the engine may have failed by fatigue due to age. However, subsequent metallurgical failure analysis revealed that the fatigue failure was caused by the presence of liquid lead (Pb) on the airfoil at the operating temperature which reacted with the nickel-base superalloy and facilitated the fatigue crack initiation. Lead was used in the manufacturing process to encapsulate the turbine blades to form a solid block for fixture support during machining of the blades. The general operating temperature in the second-stage turbine was reported as 600–700 °F, while the melting point of lead is 621 °F. Molten lead slowly penetrated and alloyed into the surface of the turbine blades during engine operation which eventually led to fatigue crack initiation sites on the high-pressure side of the blade airfoils. The process of liquid metal corrosion occurred over a long time-period of engine operation causing fatigue crack nucleation and the subsequent fatigue crack propagation time was of the order of few minutes due to the high RPM of the turbine, thus categorized as a high cycle fatigue (HCF) and making crack discovery unlikely during the maintenance inspections. The lead residue is needed to be removed completely from the turbine blades after machining during manufacturing, and therefore, the engine manufacturer was found responsible for the cause of this accident instead of inadequate maintenance, inspections, old age of the engine turbine blades or pilot error.

Similar content being viewed by others

References

T.J. Carter, Common failures in gas turbine blades. Eng. Fail. Anal. 12, 237–247 (2005)

N.E. Cherolis, D.J. Benac, W.D. Pridemore, Fatigue in rotating equipment: is it HCF or LCF? J. Fail. Anal. Prev. 16(5), 828–841 (2016)

B.A. Cowles, High cycle fatigue in gas turbine—an industry perspective. Int. J. Fract. 80, 147–163 (1996)

M. Müller, Theoretical considerations on corrosion fatigue crack initiation. Metall. Trans. A 13A, 649–655 (1982)

C.E. Price, J.K. Wood, The fatigue behavior of nickel, monel, selected superalloys, tested in liquid mercury and air; a comparison. J. Eng. Mater. Technol. 106(2), 178–183 (1986)

X. Gong, Liquid metal embrittlement of a 9Cr-1Mo ferritic-martensitic steel in lead-bismuth eutectic environment under low cycle fatigue. Ph.D. Dissertation, Department of Materials Engineering, KU Leuven, Belgium (2015)

Acknowledgments

The engine teardown investigation was conducted by James F. Irvin, the metallurgical failure analysis was performed by Dr. Arun Kumar and Dr. Syavash Ensha, and metallographic cross-sectioning was supervised by Joseph Quinn. SEM and EDX work was performed by Peggie Bennett and metallography by Morgan Hix.

Author information

Authors and Affiliations

Corresponding author

Additional information

Joseph Quinn was formerly with EAG Laboratories, 250 N. Nash Street, El Segundo, CA 90245, USA.

Rights and permissions

About this article

Cite this article

Kumar, A., Ensha, S., Irvin, J.F. et al. Liquid Metal Corrosion Fatigue (LMCF) Failure of Aircraft Engine Turbine Blades. J Fail. Anal. and Preven. 18, 939–947 (2018). https://doi.org/10.1007/s11668-018-0487-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0487-4