Abstract

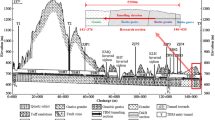

A shield machine with freezing function is proposed in order to realize tool change operation at atmospheric pressure. Furthermore, the transformation project of freezing cutterhead and tool change maintenance method are put forward. Taking the shield construction of Huanxi Power Tunnel as an example, a numerical analysis of the freezing cutter head of the project was carried out. The results show that when the brine temperature is −25 °C, after 30 d of freezing, the thickness of the frozen wall can reach 0.67 m and the average temperature drops to −9.9 °C. When the brine temperature is −30 °C, after 50 d of freezing, the thickness of the frozen wall can reach 1.01 m and the average temperature drops to −12.4 °C. If the thickness of the frozen wall is 0.5 m and the average temperature is −10 °C, as the design index of the frozen wall, the brine temperature should be lower than −28 °C to meet the excavation requirements in 30 d. Analyzing the frozen wall stress under 0.5 m thickness and −10 °C average temperature condition, the tensile safety factor and compressive safety factor are both greater than 2 at the most dangerous position, which can meet the tool change requirements for shield construction.

摘要

为了实现常压换刀作业, 提出了一种具有冻结功能的盾构机, 并且提出了冷冻刀盘的改造方案 和换刀维护方法。 以环西电力隧道盾构施工为例, 对该工程冷冻刀盘进行了数值分析。 结果表明, 当 盐水温度为−25 °C 时, 冻结30 d 后, 冻土的冻结壁厚可达0.67 m,冻土平均温度降至−9.9 °C。 当盐 水温度为−30 °C 时, 冻结50 d 后, 冻结壁厚可达1.01 m, 平均温度降至−12.4 °C 以冻结壁厚度为0.5 m, 平均温度为−10 °C 作为冻结壁设计指标时, 盐水温度应低于−28 °C, 以满足30 d 的开挖要求。 通过对 0.5 m 厚、−10 °C 平均温度下的冻结壁进行应力分析得出: 最危险位置的抗拉、抗压安全系数均大于 2, 满足盾构施工换刀要求。

Similar content being viewed by others

References

EMRE A, HANIFI C. Empirical modeling for predicting excavation performance of EPB TBM based on soil properties [J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2018, 71: 340–353. DOI: https://doi.org/10.1016/j.tust.2017.09.016.

ZHOU Hui, GAO Yang, ZHANG Chuan-qing, YANG Fan-jie, HU Ming-ming, LIU Hai-tao, JIANG Yue. A 3D model of coupled hydro-mechanical simulation of double shield TBM excavation [J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2018, 71: 1–14. DOI: https://doi.org/10.1016/j.tust.2017.07.012.

ZHAO J, GONG Q M, EISENSTEN Z. Tunnelling through a frequently changing and mixed ground: A case history in singapore [J]. Tunnelling and Underground Space Technology, 2007, 22(4): 388–400. DOI: https://doi.org/10.1016/j.tust.2006.10.002.

CHO Jung-Woo, JEON Seo-Kwon, YU Sang-Hwa, CHANG Soo-Ho. Optimum spacing of TBM disc cutters: A numerical simulation using the three-dimensional dynamic fracturing method [J]. Tunnelling and Underground Space Technology, 2010, 25(3): 230–244. DOI: https://doi.org/10.1016/j.tust.2009.11.007.

GERTSCH R, GERTSCH L, ROSTAMI J. Disc cutting tests in colorado red granite:implications for TBM performance prediction [J]. International Journal of Rock Mechanics arltl Mining Sciences, 2007, 44(2): 238–246. DOI: https://doi.org/10.1016/j.ijrmms.2006.07.007.

HUO Jun-zhou, SUN Wei, CHEN Jing. Optimal disc cutters plane layout design of the full-face rock tunnel boring machine (tbm) based on a multi-objective genetic algorithm [J]. Journal of Mechanical Science and Technology, 2010, 24(2): 521–528. DOI: https://doi.org/10.1007/s12206-009-1220-8.

ROHOLA H, JAMAL R, MARKUS T, JÜRGEN S. Parametric study of the impacts of various geological and machine parameters on thrust force requirements for operating a single shield TBM in squeezing ground [J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research, 2018, 73: 252–260. DOI: https://doi.org/10.1016/j.tust.2017.12.027.

JAFAR H. Development of an empirical model to estimate disc cutter wear for sedimentary and low to medium grade metamorphic rocks [J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2018, 75: 90i–99. DOI: https://doi.org/10.1016/j.tust.2018.02.009.

EARL M B. DE G, DYLAN S, MAROLO C A, GUY D, LUKAS U A. Large-scale direct shear testing of compacted frozen soil under freezing and thawing conditions [J]. Cold Regions Science and Technology, 2018, 151: 138–147. DOI: https://doi.org/10.1016/j.coldregions.2018.03.011.

WANG Da-yan, WANG Yong-tao, MA Wei, LEI Le-le, WEN Zhi. Study on the freezing-induced soil moisture redistribution under the applied high pressure [J]. Cold Regions Science and Technology, 2018, 145: 135–141. DOI: https://doi.org/10.1016/j.coldregions.2017.10.012.

AN Ling-shi, LING Xian-zhang, GENG Yong-chang, LI Qiong-lin, ZHANG Feng, ANTONIO B. DEM investigation of particle-scale mechanical properties of frozen soil based on the nonlinear microcontact model incorporating rolling resistance [J]. Mathematical Problems in Engineering, 2018: 2685709. DOI: https://doi.org/10.1155/2018/2685709.

FENG Xiao, GANG S, CHEN, LEROY H J, DUANE D, YANG Zhao-hui. Characterization of the viscoelastic effects of thawed frozen soil on pile by measurement of free response [J]. Cold Regions Science and Technology, 2018, 145: 229–236. DOI: https://doi.org/10.1016/j.coldregions.2017.09.011.

WANG Tao, ZHOU Guo-qing, JIANG Xiong, WANG Jian-zhou. Assessment for the spatial variation characteristics of uncertain thermal parameters for warm frozen soil [J]. Applied Thermal Engineering, 2018, 134: 484–489. DOI: https://doi.org/10.1016/j.applthermaleng.2018.02.023.

ROMAN JI T. Mechanics of frozen soil [M]. China Science Publishing & Media Ltd. (CSPM), 2016.

SURIKOV B B. Frozen soil damage mechanics [M]. China Science Publishing & Media Ltd. (CSPM), 2016.

ANDERSLAND. Frozen ground engineering [M]. China Architecture & Building Press, 2011.

HU Xiang-dong, FANG Tao, ZHANG Luo-yu. Analytical solution to temperature distribution in frozen soil wall with wavy boundaries by single-row- and double-row-piped freezing [J]. Cold Regions Science and Technology, 2018, 145: 208–228. DOI: https://doi.org/10.1016/j.coldregions.2017.10.010.

BRUN B, HA H. Underground line U5 “Unter den Linden” Berlin, Germany Structural and thermal FE-calculations for ground freezing design [C]// Proceedings of the International Conference on Numerical Simulation of Construction Processes in Geotechnical Engineering for Urban Environment. Bochum, German, 2006: 225–232.

PIMENTELA E, PAPAKONSTANTINOUB S, ANAGNOSTOU G. Numerical interpretation of temperature distributions from three ground freezing applications in urban tunneling [J]. Tunnelling and Underground Space Technology, 2012, 28(1): 57–69. DOI: https://doi.org/10.1016/j.tust.2011.09.005.

PIMENTELA E, SRES A, ANAGNOSTOU G. Large-scale laboratory tests on artificial ground freezing under seepage-flow conditions [J]. Geotechnique, 2012, 62(3): 227–241. DOI: https://doi.org/10.1680/geot.9.P.120.

WANG M S. Tunnel underground engineering technology. [M]. Beijing: China Communications Press. (in Chinese)

WANG Y. Mechanical property analysis of steel pipe-frozen soil composite structure in freeze-sealing pipe roof method [D]. Shanghai: Tongji University. (in Chinese)

ZHANG P, MA B S, ZHAO W. The largest curved pipe roofing tunnel project in the world [C]// Pipelines 2013. Pipelines and Trenchless Construction and Renewals—A Global Perspective. United States: ASCE, 2013: 953–963.

HU Xiang-dong, HONG Ze-qun, FANG Tao. Analytical solution to steady-state temperature field with typical freezing tube layout employed in freeze-sealing pipe roof method [J]. Tunnelling and Underground Space Technology, 2018, 79: 336–345. DOI: https://doi.org/10.1016/j.tust.2018.06.014.

HU Xiang-dong, HAN Lei, HAN Yan-guang. Analytical solution to temperature distribution of frozen soil wall by multi-row-piped freezing with the boundary separation method [J]. Applied Thermal Engineering, 2019, 149: 702–711. DOI: https://doi.org/10.1016/j.applthermaleng.2018.12.096.

LI Shuang-yang, ZHANG Ming-yi, PEI Wan-sheng, LAI Yuan-ming. Experimental and numerical simulations on heat-water-mechanics interaction mechanism in a freezing soil [J]. Applied Thermal Engineering, 2018, 132: 209–220. DOI: https://doi.org/10.1016/j.applthermaleng.2017.12.061.

FROUGH O, TORABI S R. An application of rock engineering systems for estimating TBM downtimes [J]. Engineering Geology, 2013, 157: 112–123. DOI: https://doi.org/10.1016/j.enggeo.2013.02.003.

GALLO J, PEREZ-ACEBO H. Performance model for micro tunnelling boring machines (MTBM) [J]. Informes de la Construction, 2017, 69: e203. DOI: https://doi.org/10.3989/id55211.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2014FJ1002) supported by the Science and Technology Major Project of Hunan Province, China; Project (2012AA041803) supported by National High Technology Research and Development Program of China

Rights and permissions

About this article

Cite this article

Dai, W., Xia, Ym., Xu, Hl. et al. Numerical simulation of freezing effect and tool change of shield machine with a frozen cutterhead. J. Cent. South Univ. 27, 1262–1272 (2020). https://doi.org/10.1007/s11771-020-4365-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4365-3