Abstract

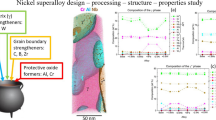

In 2006, a new-ordered L12 phase, Co3(Al,W), was discovered that can form coherently in a face-centered cubic (fcc) A1 Co matrix. Since then, a community has developed that is attempting to take these alloys forward into practical applications in gas turbines. A new candidate polycrystalline Co-Ni γ/γ′ superalloy, V208C, is presented that has the nominal composition 36Co-35Ni-15Cr-10Al-3W-1Ta (at.%). The alloy was produced by conventional powder metallurgy superalloy methods. After forging, a γ′ fraction of ~56% and a secondary γ′ size of 88 nm were obtained, with a grain size of 2.5 μm. The solvus temperature was 1000°C. The density was found to be 8.52 g cm−3, which is similar to existing Ni alloys with this level of γ′. The alloy showed the flow stress anomaly and a yield strength of 920 MPa at room temperature and 820 MPa at 800°C, similar to that of Mar-M247. These values are significantly higher than those found for either conventional solution and carbide-strengthened Co alloys or the γ/γ′ Co superalloys presented in the literature thus far. The oxidation resistance, with a mass gain of 0.08 mg cm−2 in 100 h at 800°C, is also comparable with that of existing high-temperature Ni superalloys. These results suggest that Co-based and Co-Ni superalloys may hold some promise for the future in gas turbine applications.

Similar content being viewed by others

References

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Science 312, 90 (2006).

M. Tsunekane, A. Suzuki, and T.M. Pollock, Intermetallics 19, 636 (2011).

L. Klein, Y. Shen, M.S. Killian, and S. Virtanen, Corros. Sci. 53, 2713 (2011).

A. Suzuki, G.C. DeWolf, and T.M. Pollock, Scripta Mater. 56, 385 (2007).

T.M. Pollock and A.S. Argon, Acta Metall. Mater. 40, 1 (1992).

L. Kovarik, R.R. Unocic, Ju. Li, C. Shen, Y. Wang, and M.J. Mills, Prog. Mater Sci. 54, 839 (2009).

V.A. Vorontsov, L. Kovarik, M.J. Mills, and C.M.F. Rae, Acta Mater. 60, 4866 (2012).

C.M.F. Rae and R.C. Reed, Acta Mater. 55, 1067 (2007).

D. Dye, M. Knop, H.-Y. Yan, M.C. Hardy, and H.J. Stone, GB patent application 1312000.1 (2013).

K. Shinagawa, T. Omori, J. Sato, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Mater. Trans. 49, 1474 (2008).

H.-Y. Yan, V.A. Vorontsov, and D. Dye, Intermetallics 48, 44 (2014).

A. Bauer, S. Neumeier, F. Pyczak, and M. Göken, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman (Warrendale, PA: The Minerals, Metals & Materials Society; Hoboken, NJ: John Wiley & Sons, 2012), pp. 695–703.

T.P. Gabb, J. Gayda, J. Telesman, and P. Kantzos, Thermal and Mechanical Property Characterization of the Advanced Disk Alloy LSHR, Technical Report No. NASA/TM2005-213645 (Washington, DC: NASA, 2005).

S. Meher, H.Y. Yan, S. Nag, D. Dye, and R. Banerjee, Scripta Mater. 67, 850 (2012).

R.J. Mitchell, H.Y. Li, and Z.W. Huang, J. Mater. Process. Technol. 209, 1011 (2009).

A. Cerezo, P.H. Clifton, M.J. Galtrey, C.J. Humphreys, T.F. Kelly, D.J. Larson, S. Lozano-Perez, E.A. Marquis, R.A. Oliver, G. Sha, K. Thompson, M. Zandbergen, and R.L. Alvis, Mater. Today 10, 36 (2007).

T.F. Kelly and D.J. Larson, Mater. Charact. 44, 59 (2000).

K. Thompson, D. Lawrence, D.J. Larson, J.D. Olson, T.F. Kelly, and B. Gorman, Ultramicroscopy 107, 131 (2007).

O.C. Hellman, J.A. Vandenbroucke, J. Rüsing, D. Isheim, and D.N. Seidman, Microsc. Microanal. 6, 437 (2000).

S. Meher and R. Banerjee, Intermetallics 49, 138 (2014).

J.Y. Hwang, R. Banerjee, J. Tiley, R. Srinivasan, G.B. Viswanathan, and H.L. Fraser, Metall. Mater. Trans. A 40, 24 (2009).

R.C. Reed, The Superalloys—Fundamentals and Applications, 1st ed. (Cambridge, MA: Cambridge University Press, 2006).

A. Suzuki and T.M. Pollock, Acta Mater. 56, 1288 (2008).

M.J. Donachie, Superalloys: A Technical Guide (Materials Park, OH: ASM International, 2002).

M. Knop, V.A. Vorontsov, M.C. Hardy, and D. Dye, Proceedings of the Eurosuperalloys 2014, Hyères, France, May 2014. MATEC Web of Conferences, vol. 14 (2014), p. 18003. doi:10.1051/matecconf/20141418003.

H.-Y. Yan, V.A. Vorontsov, and D. Dye, Corros. Sci. 83, 382 (2014).

M.S. Titus, A. Suzuki, and T.M. Pollock, Scripta Mater. 66, 574 (2012).

M.S. Titus, A. Suzuki, and T.M. Pollock, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella and J. Telesman (Warrendale, PA: The Minerals, Metals & Materials Society; Hoboken, NJ: John Wiley & Sons, 2012), pp. 823–832.

Y.M. Eggeler, M.S. Titus, A. Suzuki, and T.M. Pollock, Acta Mater. 77, 352 (2014).

T.M. Pollock, J. Dibbern, M. Tsunekane, and A. Suzuki, JOM 62 (1), 58 (2010).

K. Shinagawa, T. Omori, K. Oikawa, R. Kainuma, and K. Ishida, Scripta Mater. 61, 612 (2009).

L. Klein, A. Bauer, S. Neumeier, M. Göken, and S. Virtanen, Corros. Sci. 53, 2027 (2011).

H.S. Kitaguchi, H.Y. Li, H.E. Evans, R.G. Ding, I.P. Jones, P. Baxter, and G. Bowen, Acta Mater. 61, 1968 (2013).

R. Jiang, S. Everitt, M. Lewandowski, N. Gao, and P.A.S. Reed, Int. J. Fatigue 62, 217 (2014).

M. Ooshima, K. Tanaka, N.L. Okamoto, K. Kishida, and H. Inui, J. Alloys Compd. 508, 71 (2010).

A. Bauer, S. Neumeier, F. Pyczak, and M. Göken, Scripta Mater. 63, 1197 (2010).

K. Ishida, Proc. Eurosuperalloys 2014 (in press).

Acknowledgements

The authors would like to acknowledge the financial support provided by Rolls-Royce plc, Imperial College London, and EPSRC (U.K.) Grant EP/H022309/1. Useful conversations with Drs Vassili Vorontsov, Hui-Yu Yan (Imperial), and Howard Stone (Cambridge) are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Knop, M., Mulvey, P., Ismail, F. et al. A New Polycrystalline Co-Ni Superalloy. JOM 66, 2495–2501 (2014). https://doi.org/10.1007/s11837-014-1175-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1175-9