Abstract

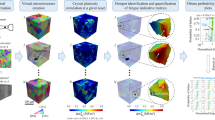

A data-driven mechanistic modeling technique is applied to a system representative of a broken-up inclusion (“stringer”) within drawn nickel-titanium wire or tube, e.g., as used for arterial stents. The approach uses a decomposition of the problem into a training stage and a prediction stage. It is applied to compute the fatigue crack incubation life of a microstructure of interest under high-cycle fatigue. A parametric study of a matrix–inclusion–void microstructure is conducted. The results indicate that, within the range studied, a larger void between halves of the inclusion increases fatigue life, while larger inclusion diameter reduces fatigue life.

Similar content being viewed by others

References

A. Pelton, V. Schroeder, M. Mitchell, X.Y. Gong, M. Barney, and S. Robertson, J. Mech. Behav. Biomed. Mater. 1, 153 (2008)

S. Adlakha, M. Sheikh, J. Wu, M.W. Burket, U. Pandya, W. Colyer, E. Eltahawy, and C.J. Cooper, J. Interv. Cardiol. 23, 411 (2010)

M. Rahim, J. Frenzel, M. Frotscher, J. Pfetzing-Micklich, R. Steegmüller, M. Wohlschlögel, H. Mughrabi, and G. Eggeler, Acta Mater. 61, 3667 (2013)

F. Sczerzenie, G. Vergani, and C. Belden, J. Mater. Eng. Perform. 21, 2578 (2012)

N. Salajegheh, R. Prasannavenkatesan, D.L. McDowell, G.B. Olson, and H.J. Jou, J. Eng. Mater. Technol. 136, 031003 (2014)

R. Prasannavenkatesan, J. Zhang, D.L. McDowell, G.B. Olson, and H.J. Jou, Int. J. Fatigue 31, 1176 (2009)

J.A. Moore, D. Frankel, R. Prasannavenkatesan, A.G. Domel, G.B. Olson, and W.K. Liu, Int. J Fatigue 91, 183 (2016)

A. Fatemi and D.F. Socie, Fatigue Fract. Eng. Mater. Struct. 11, 149 (1988)

G.M. Owolabi and H.A. Whitworth, J. Mater. Sci. Technol. 30, 203 (2014)

Z. Liu, O.L. Kafka, C. Yu, and W.K. Liu, Data-driven self-consistent clustering analysis of heterogeneous materials with crystal plasticity, in Advances in Computational Plasticity: A Book in Honour of D. Roger J. Owen, ed. E. Oñate, D. Peric, E. de Souza Neto, M. Chiumenti (Springer International, 2018), pp. 221–242

Z. Liu, M. Bessa, and W. Liu, Comput. Methods Appl. Mech. Eng. 306, 319 (2016)

H. Moulinec and P. Suquet, Comput. Methods Appl. Mech. Eng. 157, 69 (1998)

J. MacQueen, Proceedings of the Fifth Berkeley Symposium on Mathematics Statistics and Probability p. 281 (1967)

M. Kabel, T. Böhlke, and M. Schneider, Comput. Mech. 54, 1497 (2014)

R.D. McGinty, Multiscale Representation of Polycrystalline Inelasticity, Ph.D. thesis, Geogia Tech (2001)

C.H. Goh, R.W. Neu, and D.L. McDowell, Int. J. Plast. 19, 1627 (2003)

M. Shenoy, J. Zhang, and D. McDowell, Fatigue Fract. Eng. Mater. Struct. 30, 889 (2007)

G.M. Owolabi, R. Prasannavenkatesan, and D.L. McDowell, Int. J. Fatigue 32, 1378 (2010)

H. Sehitoglu, J. Jun, X. Zhang, I. Karaman, Y. Chumlyakov, H. Maier, and K. Gall, Acta Mater. 49, 3609 (2001)

S.W. Robertson, M. Launey, O. Shelley, I. Ong, L. Vien, K. Senthilnathan, P. Saffari, S. Schlegel, and A.R. Pelton, J. Mech. Behav. Biomed. Mater. 51, 119 (2015)

Acknowledgements

C.Y., M.S., and W.K.L. thank the National Institute of Standards and Technology and Center for Hierarchical Materials Design (CHiMaD) under Grant Nos. 70NANB13Hl94 and 70NANB14H012; W.K.L. also acknowledges the support of the AFOSR. O.L.K. thanks the National Science Foundation (NSF) for their support through the NSF Graduate Research Fellowship Program (GRFP) under financial Award Number DGE-1324585.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Kafka, O.L., Yu, C., Shakoor, M. et al. Data-Driven Mechanistic Modeling of Influence of Microstructure on High-Cycle Fatigue Life of Nickel Titanium. JOM 70, 1154–1158 (2018). https://doi.org/10.1007/s11837-018-2868-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2868-2