Abstract

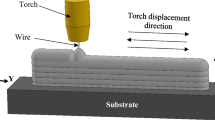

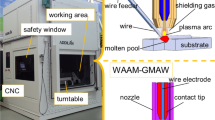

Wire and arc additive manufacturing (WAAM) is becoming an increasingly important process for manufacture of components with complex geometry, being used for products made for products made from expensive metals such as Inconel 625. The shielding gas used to protect the molten metal is one of the key process parameters due to its significant impact on the structure and mechanical properties of the final product. In this study, four samples were made using different shielding gas mixtures. Due to its high productivity, a metal active gas (MAG) welding process was used. Process stability and productivity rate were the main criteria used to determine the optimal range of welding parameters. Geometrical characteristics of the produced structures were analyzed. Finally, destructive tests were conducted on test specimens, and the data analyzed. The influence of the shielding gas composition on the structure and mechanical properties was determined, and conclusions are drawn.

Similar content being viewed by others

References

R. Huang, M. Riddle, D. Graziano, J. Warren, S. Das, S. Nimbalkar, J. Cresko, and E. Masanet, J. Clean. Prod. 135, 1559 (2016).

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal, and P. Colegrove, Mater. Sci. Technol. 32, 641 (2016).

A. Zinoviev, O. Zinovieva, V. Ploshikhin, V. Romanova, and R. Balokhonov, Mater. Des. 106, 321 (2016).

F. Liu, X. Lin, M. Song, H. Yang, K. Song, P. Guo, and W. Huang, J. Alloys Compd. 689, 225 (2016).

B.A. Szost, S. Terzi, F. Martina, D. Boisselier, A. Prytuliak, T. Pirling, M. Hofmann, and D.J. Jarvis, Mater. Des. 89, 559 (2015).

Y. Oguzhan and A.U. Adnan, Proc. Inst. Mech. Eng. B J. Eng. Manuf. 230, 1781 (2016).

B. Yin, H. Ma, J. Wang, K. Fang, H. Zhao, and Y. Liu, Mater. Lett. 190, 64 (2016).

D. Ding, Z. Pan, S.V. Duin, H. Li, and C. Shen, Materials 9, 652 (2016).

F. Martina, M.J. Roy, B.A. Szost, S. Terzi, P.A. Colegrove, S.W. Williams, P.J. Withers, J. Meyer, and M. Hofmann, Mater. Sci. Technol. 32, 1439 (2016).

F. Martina and S. Williams, Report: Welding Engineering and Laser Processing Centre, ver. 1.0, 2015, Cranfield University (2015)

A. Busachi, A.J. Erkoyuncu, F. Martina, and J. Ding, Proc. CIRP 37, 48 (2015).

R. Sun, L. Li, Y. Zhu, W. Guo, P. Peng, B. Cong, J. Sun, Z. Che, B. Li, C. Guo, and L. Liu, J. Alloys Compd. 747, 255 (2018).

Y. Li, Q. Han, G. Zhang, and I. Horváth, Int. J. Adv. Manuf. Technol. 96, 3331 (2018).

J. Xiong, Y. Li, R. Li, and Z. Yin, J. Mater. Process. Technol. 252, 128 (2018).

J. Ding, P.A. Colegrove, J. Mehnen, S. Ganguly, P.M. Sequeira Almeida, F. Wang, and S. Williams, Comput. Mater. Sci. 50, 3315 (2011).

R.J. Moat, A.J. Pinkerton, L. Li, P.J. Withers, and M. Preuss, Mater. Sci. Eng. A 528, 2288 (2011).

EN ISO 18274:2010 Welding consumables—solid wire electrodes, solid strip electrodes, solid wires and solid rods for fusion welding of nickel and nickel alloys—classification

EN ISO 6892-1:2016 Metallic materials—tensile testing—part 1: method of test at room temperature

Acknowledgements

This research was supported by COST Action CA15102 – “Solutions for Critical Raw Materials Under Extreme Conditions” (CRM-EXTREME).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jurić, I., Garašić, I., Bušić, M. et al. Influence of Shielding Gas Composition on Structure and Mechanical Properties of Wire and Arc Additive Manufactured Inconel 625. JOM 71, 703–708 (2019). https://doi.org/10.1007/s11837-018-3151-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3151-2