Abstract

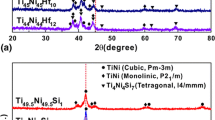

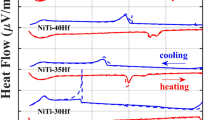

The deformation behavior, microstructure, phase composition, and mechanical and functional properties of Ti-50.9 at.%Ni shape memory alloy during uniaxial compression in the temperature range from 25°C to 1000°C have been analyzed and are discussed herein. It was found that the deformation temperature of 300°C marked a boundary for the transition from the low- to high-temperature type of flow curves; achievement of the steady-state deformation stage was observed across a wide range of deformation temperatures. Following comprehensive analysis of the obtained data, the temperature ranges of the dynamic processes of recovery, polygonization, and recrystallization of the Ti-50.9 at.%Ni alloy were determined. Deformation in the range of dynamic polygonization is accompanied by not only the formation of B2-austenite and R-phase, but also the precipitation of fine Ti3Ni4 particles during deformational aging. The highest shape recovery characteristics were obtained after deformation of the Ti-50.9 at.%Ni alloy in the temperature range from 300°C to 600°C.

Similar content being viewed by others

References

T.W. Duerig, K.N. Melton, D. Stôckel, and C.M. Wayman, Engineering Aspects of Shape Memory Alloys, 1st ed. (London: Butterworth-Heinemann, 1990), p. 499.

B. Culshaw, Smart Structures and Materials (Boston: Artech House, 1996), p. 207.

K. Otsuka and X. Ren, Intermetallics 7, 511–528 (1999).

V. Brailovski, S. Prokoshkin, P. Terriault, and P. Trochu, Shape Memory Alloys: Fundamentals, Modeling and Applications (Montreal: ETS, 2003), p. 851.

J.M. Jany, M. Leary, A. Subic, and M.A. Gibson, Mater. Des. 56, 1078–1113 (2014).

N. Resnina and V. Rubanik, Shape Memory Alloys: Properties, Technologies, Opportunities (Praffikon: Trans Tech, 2015), p. 641.

B.S. Shariat, Q. Meng, A.S. Mahmud, Z. Wu, R. Bakhtiari, J. Zhang, and Y. Liu, Mater. Des 124, 225–237 (2017).

Sun, Q., Matsui, R., Takeda, K., Pieczyska, E, Advances in Shape Memory Materials: In Commemoration of the Retirement of Professor Hisaaki Tobushi. (New York, NY: Springer, 2017), p. 241.

Gunther V.E., Hodorenko V.N., Yasenchuk Y.F., Chekalkin T.L, Titanium Nickelide. Medical Supplies of the New Generation. (Tomsk: Publishing House of the MIC, 2006), p. 296.

S.D. Prokoshkin, L.M. Kaputkina, and S.A. Bondareva, Phys. Met. Metallogr. 3, 144–149 (1991).

S. Miyazaki and K. Otsuka, ISIJ Int. 29, 353–377 (1979).

T. Todoroki and H. Tamura, Trans. Jpn. Inst. Met 28, 83–94 (1987).

S. Miyazaki, T. Imai, and Y. Igo, Metall. Trans. A 17, 115–120 (1986).

Y. Liu and P.G. McCormick, ISIJ Int. 29, 417–422 (1989).

V. Brailovski, I.Y. Khmelevskaya, S.D. Prokoshkin, V.G. Pushin, E.P. Ryklina, and R.Z. Valiev, Phys. Met. Metallogr. 97, 3–55 (2004).

S.D. Prokoshkin, V. Brailovski, I.Y. Khmelevskaya, S. Dobatkin, K. Inaekyan, V. Demers, and E. Tatyanin, Met. Sci. Heat Treat 47, 182–187 (2005).

V. Brailovski, S. Prokoshkin, I. Khmelevskaya, K. Inaekyan, V. Demers, S. Dobatkin, and E. Tatyanin, Mater. Trans. JIM 47, 795–804 (2006).

S.D. Prokoshkin, V. Brailovski, K.E. Inaekyan, V. Demers, I.Y. Khmelevskaya, S.V. Dobatkin, and E.V. Tatyanin, Mater. Sci. Eng. A 481, 114–118 (2008).

V. Brailovski, S. Prokoshkin, K. Inaekyan, and V. Demers, J. Alloys Compd. 509, 2066–2075 (2011).

R.Z. Valiev and I.V. Aleksandrov, Nanostructural Materials Obtained by Severe Plastic Deformation (Moscow: Integratsiya, 2000), p. 272.

R.Z. Valiev and T.G. Langdon, Prog. Mater. Sci 51, 881–981 (2006).

A.I. Lotkov, V. Grishkov, O. Kashin, A. Baturin, D. Zhapova, and V. Timkin, Mater. Sci. Found 81, 245–259 (2015).

A.I. Lotkov, V.N. Grishkov, E.F. Dudarev, Y.N. Koval, N.V. Girsova, O.A. Kashin, and D.Y. Zhapova, Inorg. Mater. Appl. Res 2, 548–555 (2011).

IYu Khmelevskaya, R.D. Karelin, S.D. Prokoshkin, V.A. Andreev, V.S. Yusupov, M.M. Perkas, V.V. Prosvirnin, A.E. Shelest, and V.S. Komarov, Phys. Met. Metallogr 118, 279–287 (2017).

V. Komarov, I. Khmelevskaya, R. Karelin, S. Prokoshkin, M. Zaripova, M. Isaenkova, G. Korpala, and R. Kawalla, J. Alloys Compd 797, 842–848 (2019).

I. Khmelevskaya, V. Komarov, R. Kawalla, S. Prokoshkin, and G. Korpala, J. Mater. Eng. Perform 26, 4011–4019 (2017).

I. Khmelevskaya, V. Komarov, R. Kawalla, S. Prokoshkin, and G. Korpala, Mater. Today Proc. 4, 4830–4835 (2017).

S. Prokoshkin, I. Khmelevskaya, V. Andreev, R. Karelin, V. Komarov, and A. Kazakbiev, Mater. Sci. Forum 918, 71–76 (2018).

S.D. Prokoshkin, A.V. Korotitskiy, V. Brailovski, S. Turenne, I.Y. Khmelevskaya, and I.B. Trubitsina, Acta Mater 52, 4479–4492 (2004).

V.A. Likhachev, S.L. Kuzmin, and Z.P. Kamentseva, Shape memory effect (Saint-Petersburg: Saint-Petersburg University Publishing House, 1987), p. 216.

S. Prokoshkin, V. Brailovski, A.V. Korotitskiy, K.E. Inaekyan, and A.M. Glezer, Phys. Met. Metallogr 110, 289–303 (2010).

Acknowledgements

The reported study was funded by RFBR (Project No. 19-33-60090) and part of the TEM and X-ray analyses by the Ministry of Science and Higher Education of the Russian Federation within the framework of the State Task (Project Code 0718-2020-0030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Komarov, V., Khmelevskaya, I., Karelin, R. et al. Deformation Behavior, Structure, and Properties of an Aging Ti-Ni Shape Memory Alloy after Compression Deformation in a Wide Temperature Range. JOM 73, 620–629 (2021). https://doi.org/10.1007/s11837-020-04508-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04508-7