Abstract

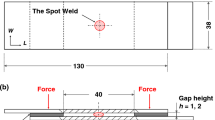

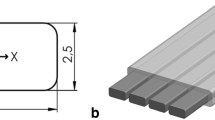

Roll coating is a comparatively simple and common technology for coating of continuous substrates like paper, coils, or foils, where the fluid is metered through the gap between two rolls. Rolls wrapped with a deformable rubber layer enable a precise metering for low fluid amounts and lead additionally to higher process stability. Many efforts have been made to investigate the influencing factors of deformable roll coating by experimental and numerical methods. Beside configurations with positive gaps, which are comparable to rigid roll setups, negative gaps, where only the elasticity of the rubber layer prevents overlapping of the rolls, are of interest as such configurations enable thin liquid layers. The main influencing factors on the volume flow rate through the gap are viscosity, average velocity, effective radius, Young’s modulus, load or pre-set gap height, and partly rubber thickness, when an influence of the layer height is assumed. The dependency is often given in empirically or numerically based power law relationships. In contrast to this, in the present study, an analytically based solution is used to investigate the influencing factors in deformable roll coating with negative gaps. This continues the authors' previous work, in which the analytical solution was derived. As a result, a general agreement with numerical and experimental results from literature is found. Additionally, the analytical approach allows for the first time the ability to quantify further trends. The proposed power law exponent for the dimensionless load and elasticity numbers from literature cannot be considered as constant in the whole common application range of roll coating but remarkable trends appear. Additionally, a new criterion for the critical rubber cover thickness is developed analytically which describes the limit value of the negligible influence of the rubber cover thickness on the volume flow rate. The present investigation enables the explanation of different literature results and offers a more general view in the understanding of roll coating processes.

Similar content being viewed by others

References

Szczurek, E, Dubar, M, Deltombe, R, Dubois, A, Dubar, L, “New Approach to the Evaluation of the Free Surface Position in Roll Coating.” J. Mater. Process. Technol., 209 3187–3197 (2009)

Carvalho, MS, Scriven, LE, “Three-Dimensional Stability Analysis of Free Surface Flows: Application to Forward Deformable Roll Coating.” J. Comp. Phys., 151 534–562 (1999)

Cohu, O, Magnin, A, “Forward Roll Coating of Newtonian Fluids with Deformable Rolls: An Experimental Investigation.” Chem. Eng. Sci., 52 1339–1347 (1997)

Kang, Y-T, Lee, K-Y, Liu, T-J, “The Effect of Polymer Additives on the Performance of a Two-Roll Coater.” J. Appl. Polym. Sci., 43 1187–1195 (1991)

Varnam, CJ, Hooke, CJ, “Non-Hertzian Elastohydrodynamic Contacts: An Experimental Investigation.” J. Mech. Eng. Sci., 19 189–192 (1977)

Jaffar, MJ, “Estimation of Minimum Thickness for Line Contacts in the Transition Region Between the Isoviscous, Elastic and the Piezoviscous-Elastic Lubrication Regimes.” Proc. Inst. Mech. Eng. C, 203 379–386 (1989)

Johnson, KL, “Regimes of Elastohydrodynamic Lubrication.” J. Mech. Eng. Sci., 12 (1) 9–16 (1970)

Ascanio, G, Ruiz, G, “Measurement of Pressure Distribution in a Deformable Nip of Counter-Rotating Rolls.” Meas. Sci. Technol., 17 2430–2436 (2006)

Ascanio, G, Carreau, PJ, Tanguy, PA, “High-Speed Roll Coating with Complex Rheology Fluids.” Exp. Fluids., 40 1–14 (2006)

Gasni, D, Ultrasonic Reflection for Measurement of Oil Film Thickness and Contact between Dissimilar Materials. PhD Thesis, University of Sheffield, 2012

Coyle, DJ, “Forward Roll Coating with Deformable Rolls: A Simple One-Dimensional Elastohydrodynamic Model.” Chem. Eng. Sci., 43 2673–2684 (1988)

Carvalho, MS, Scriven, LE, “Flows in Forward Deformable Roll Coating Gap: Comparison between Spring and Plane-Strain Models of Roll Cover.” J. Comp. Phys., 138 449–479 (1997)

Gostling, MJ, Savage, MD, Young, AE, Gaskell, PH, “A Model for Deformable Roll Coating with Negative Gaps and Incompressible Compliant Layers.” J. Fluid. Mech., 489 155–184 (2003)

Bohan, MFJ, Fox, IJ, Claypole, TC, Gethin, DT, “Numerical Modelling of Elastohydrodynamic Lubrication in Soft Contacts Using Non-Newtonian Fluids.” Int. J. Numer. Methods Heat Fluid Flow, 12 494–511 (2002)

Carvalho, MS, Scriven, LE, “Effect of Deformable Roll Cover on Roll Coating.” Tappi J., 77 201–208 (1994)

Lécuyer, HA, Mmbaga, JP, Hayes, RE, Bertrand, FH, Tanguy, PS, “Modelling of Forward Roll Coating Flows with a Deformable Roll: Application to Non-Newtonian Industrial Formulations.” Comp. Chem. Eng., 33 1427–1437 (2009)

Greener, J, Middleman, S, “Theoretical and Experimental Studies of the Fluid Dynamics of a Two-Roll Coater.” Ind. Eng. Chem. Fundam., 18 35–41 (1979)

Savage, MD, “Mathematical Models for Coating Processes.” J. Fluid Mech., 117 443–455 (1982)

Abbott, SJ, Kapur, N, Sleigh, PA, Summers, JL, Thompson, HM, “A Review of Deformable Roll Coating Systems.” Convertech & e-Print, 1 (3) 89–93 (2011)

Carvalho, MS, “Effect of Thickness and Viscoelastic Properties of Roll Cover on Deformable Roll Coating Flows.” Chem. Eng. Sci., 58 4323–4433 (2003)

Coyle, DJ, “Nonlinear Theory of Squeeze-Roll Coating.” AIChE Spring National Meeting, Florida, USA, 1990

Hooke, CJ, O’Donoghue, JP, “Elastohydrodynamic Lubrication of Soft, Highly Deformed Contacts.” J. Mech. Eng. Sci., 14 34–48 (1972)

Johnson, MA, Viscoelastic Roll Coating Flows. PhD thesis, University of Maine, 2003

Kistler, SF, Schweizer, PM, Liquid Film Coating—Scientific Principles and Their Technological Implications. Chapman & Hall, London, 1997

Herrebrugh, K, “Solving the Incompressible and Isothermal Problem in Elastohydrodynamic Lubrication Through an Integral Equation.” J. Lubric. Technol., 90 262–270 (1968)

Roberts, AF, Swales, PD, “The Elastohydrodynamic Lubrication of a Highly Elastic Cylindrical Surface.” Br. J. Appl. Phys., 2 1317–1327 (1969)

Willinger, B, Delgado, A, “Analytical Prediction of Roll Coating with Counter-Rotating Deformable Rolls.” J. Coat. Technol. Res., 11 31–37 (2014)

Willinger, B, Epple, P, Delgado, A, “Analytical Model for Deformable Roll Coating with Nip Feed.” Proc. Appl. Math. Mech., 12 599–600 (2012)

Durst, F, Grundlagen der Strömungsmechanik - Eine Einführung in die Theorie der Strömungen von Fluiden. Springer, Berlin, 2006

Parish, GJ, “Measurement of Pressure Distribution Between Metal and Rubber Covered Rollers.” Br. J. Appl. Phys., 9 158–161 (1958)

Hannah, M, “Contact Stress and Deformation in a Thin Elastic Layer.” Q. J. Mech. Appl. Math., 3 94–105 (1950)

Hertz, H, “Über die Berührung fester elastischer Körper.” J. Reine Angew. Math., 92 156–171 (1881)

Parish, GJ, “Apparent Slip Between Metal and Rubber-Covered Pressure Rollers.” Br. J. Appl. Phys., 9 428–433 (1958)

Thomas, HR, Hoersch, VA, “Stresses Due to the Pressure of One Elastic Solid Upon Another.” University of Illinois, Engineering Experimental Station Bulletin, 21 66–99 (1930)

Parish, GJ, “Calculation of the Behaviour of Rubber-Covered Pressure Rollers.” Br. J. Appl. Phys., 12 333–336 (1961)

Cohen, ED, Gutloff, EB, Modern Coating and Drying Technology. Wiley-VCH, New York, 1992

Benkreira, H, Edwards, MF, Wilkinson, WL, “A Semi-empirical Model of the Forward Roll Coating Flow of Newtonian Fluids.” Chem. Eng. Sci., 36 423–427 (1981)

Benkreira, H, Edwards, MF, Wilkinson, WL, “Roll Coating of Purely Viscous Liquids.” Chem. Eng. Sci., 36 429–434 (1981)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grashof, B., Delgado, A. Analysis of influencing parameters in deformable roll coating of counter-rotating rolls. J Coat Technol Res 12, 63–73 (2015). https://doi.org/10.1007/s11998-014-9629-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-014-9629-0