Abstract

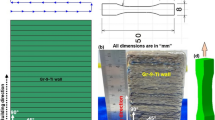

Forming is the process in which deformation of the material takes place in a requisite die cavity without any failure. During this, bi-directional stretching and compression of the material takes place which results in defects necking, cracking and wrinkling. The challenges are different when same process is carried out at micro level with thin sheets below 100 microns. It has become imperative for many engineering fields to manufacture micro-sized components, due to growing miniaturization. It is also observed that the mechanical behavior of thin sheets differs greatly at the micro-level. Forming limit curve (FLC) is one way by which the formality of material can be assessed. The FLC can be plotted using three approaches—experimentally, empirically, and numerically. In this research, FLC is plotted experimentally for an ultra-thin Titanium sheet of 50 µm. A newly designed tool with hemispherical punch of 4 mm diameter was used for experimentation according to ASTM-2218-14 standard using samples of Uni-Axial, Intermediate Uni-Axial, Bi-Axial, Intermediate Bi-Axial, and Plane Strain paths to obtain limit strains. The objective of this research is to plot FLC with microstructural study to assess the behavior of Titanium Grade-II (TiG-II). For Numerical simulation M–K model was applied. The Numerical results and experimental results achieved are in good agreement. Micro structural study reveals phase identification and grain size assessment.

Similar content being viewed by others

References

Razali, A.R., Qin, Yi.: A review on micro-manufacturing, micro-forming and their key issues. Procedia Eng. 53, 665–672 (2013). https://doi.org/10.1016/j.proeng.2013.02.086

Jian, C., Krishnan, N., Wang, Z., Lu, H., Liu, W.K., Swanson, A.: Microforming: experimental investigation of the extrusion process for micro pins and its numerical simulation using RKEM. J. Manuf. Sci. Eng. 126(4), 642–652 (2005). https://doi.org/10.1115/1.1813468

Leu, D.-K.: Modeling of size effect on tensile flow stress of sheet metal in microforming. J. Manuf. Sci. Eng. 131(1), 011001–011008 (2009). https://doi.org/10.1115/1.3039520

Kim, G.-Y., Ni, J., Koç, M.: Modeling of the size effects on the behavior of metals in microscale deformation processes. J. Manuf. Sci. Eng. 129(3), 470 (2007). https://doi.org/10.1115/1.2714582

Yin, H., Jiang, Z., Xie, H., Jia, F., Wang, X., Zhou, C.: Micro forming of metallic composites. Procedia Manuf. 15, 1429–1436 (2018). https://doi.org/10.1016/j.promfg.2018.07.338

Laxman, H.V., Srivatsa, S.R.: Sheet metal forming processes—recent technological advances. Mater. Today Proc. 5(1), 2564–2574 (2018). https://doi.org/10.1016/j.matpr.2017.11.040.8

Zhang, R., Shao, Z., Lin, J.: A review on modelling techniques for formability prediction of sheet metal forming. Int. J. Light. Mater. Manuf. 1(3), 115–125 (2018). https://doi.org/10.1016/j.ijlmm.2018.06.003

Yasunori, S., Yasuda, K., Kaga, H.: Micro deep drawability of very thin sheet steels. J. Mater. Process. Technol. 113(1–3), 641–647 (2001). https://doi.org/10.1016/S0924-0136(01)00626-4

Xu, Z.T., Peng, L.F., Fu, M.W., Lai, X.M.: Size effect affected formability of sheet metals in micro/meso scale plastic deformation: experiment and modeling. Int. J. Plast. 68, 34–54 (2015). https://doi.org/10.1016/j.ijplas.2014.11.002

Lai, X.M., Fu, M.W., Peng, L.F.: Sheet metal meso- and microforming and their industrial applications. CRC Press Taylor, Boca Raton (2020)

Peng, L.F., Xu, Z.T., Fu, M.W., Lai, X.M.: Forming limit of sheet metals in meso-scale plastic forming by using different failure criteria. Int. J. Mech. Sci. 120, 190–203 (2016)

Michael, A., Scholting, M.E., Droog, J.M.M.: A new method for predicting Forming Limit Curves from mechanical properties, Tata Steel Research Development & Technology, Netherlands. J. Mater. Process. Technol. 213, 759–769 (2013)

Wolfgang, B., Deng, Z., Papamantellos, K., Gusek, C.O.: A comparative study of the forming-limit diagram models for sheet steels. J. Mater. Process. Technol. 83(1–3), 223–230 (1998)

Peng, L., Xu, Z., Gao, Z., Fu, M.W.: A constitutive model for metal plastic deformation at micro/meso scale with consideration of grain orientation and its evolution. Int. J. Mech. Sci. 138–139, 74–85 (2018)

Qiua, T.T., Houb, Y.K., Caoc, H.L.: Review of Research Progress on Size Effect in Micro-Forming, vol. 717, pp. 118–121 (2017) https://doi.org/10.4028/www.scientific.net/KEM.717.118

Messner, A., Engel, U., Kals, R., Vollertsen, F.: Size effect in the FE-simulation of micro-forming processes. J. Mater. Process. Technol. 45(1–4), 371–376 (1994). https://doi.org/10.1016/0924-0136(94)90368-9

Barbier, C., Thibaud, S., Richard, F., Picart, P.: Size effects on material behavior in microforming. Int. J. Mater. Form. 2, 625 (2009). https://doi.org/10.1007/s12289-009-0563-0

Wang, J.L., Fu, M.W., Ran, J.Q.: Analysis of size effect on flow-induced defect in micro-scaled forming process. Int. J. Adv. Manuf. Technol. 73, 1475–1484 (2014). https://doi.org/10.1007/s00170-014-5947-8

Furukawa, M., Iwahashi, Y., Horita, Z., Nemoto, M., Langdon, T.G.: The shearing characteristics associated with equal-channel angular pressing. Mater. Sci. Eng. A257, 328 (1998)

Geetha, M., Singh, A.K., Asokamani, R., Gogia, A.K.: Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Progr. Mater. Sci. 54(3), 397–425 (2009). https://doi.org/10.1016/j.pmatsci.2008.06.004

McKay, G.C., Mcnair, R., MacDonald, C., Grant, M.H.: Interactions of orthopaedic metals with an immortalized rat osteoblast cell line. Biomaterials 17, 1339 (1996)

Mashalkar, A., Kakandikar, G., Nandedkar, V.: Microforming analysis of ultra-thin brass foil. Mater. Manuf. Process. 34(13), 1509–1515 (2019). https://doi.org/10.1080/10426914.2019.1655158

Patel, G., Kakandikar, G.M., Kulkarni, O.: Experimental and numerical investigations on forming limit curves in micro forming. Adv. Mater. Process. Technol. (2020). https://doi.org/10.1080/2374068X.2020.1793268

Patel, G., Kakandikar, G.: Chapter seven - Investigations on effect of thickness and rolling direction of thin metal foil on forming limit curves in microforming process. In: Kumar, K., Paulo Davim, J. (eds.) Woodhead Publishing Reviews: Mechanical Engineering Series, Modern Manufacturing Processes, pp. 145–155. Woodhead Publishing, Sawston (2020). https://doi.org/10.1016/B978-0-12-819496-6.00007-5

Swift, H.W.: Plastic instability under plane stress. J. Mech. Phys. Solids 1, 1–18 (1952)

Hill, R.: On discontinuous plastic stated, with special reference to localized necking in thin sheets. J. Mech. Phys. Solids 1, 19–30 (1952)

Manopulo, N., Hora, P., Peters, P., Gorji, M., Barlat, F.: An extended Modified Maximum Force Criterion for the prediction of localized necking under non-proportional loading. Int. J. Plast. 75, 189–203 (2015)

Marciniak, Z., Kuczyński, K.: Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 9, 609–620 (1967)

Li, X.-Q., Dong, H.-R., Wang, H.-B., Guo, G.-Q., Li, D.-S.: Effect of strain rate difference between inside and outside groove in M−K model on prediction of forming limit curve of Ti6Al4V at elevated temperatures. Trans. Nonferr. Met. Soc. China 30, 405–416 (2020)

Mjali, K.V., Botes, A.: Microstructure and mechanical properties of laser and mechanically formed commercially pure grade 2 titanium plates, titanium alloys—novel aspects of their manufacturing and processing, Maciej Motyka, Waldemar Ziaja and Jan Sieniawsk. IntechOpen (2018). https://doi.org/10.5772/intechopen.81807

Sordi, V.L., Ferrante, M., Kawasaki, M., Langdon, T.G.: Microstructure and tensile strength of grade 2 titanium processed by equal-channel angular pressing and by rolling. J. Mater. Sci. 47, 7870–7876 (2012). https://doi.org/10.1007/s10853-012-6593-x

Nie, M., Wang, C.T., Minghong, Qu., Gao, N., Wharton, J.A., Langdon, T.G.: The corrosion behaviour of commercial purity titanium processed by high-pressure torsion. J. Mater. Sci.. 49, 2824–2831 (2014). https://doi.org/10.1007/s10853-013-7988-z

Palanivel, R., Laubscher, R.F., Dinaharan, I., Hattingh, D.G.: Microstructure and mechanical characterization of continuous drive friction welded grade 2 seamless titanium tubes at different rotational speeds. Int. J. Press. Vessels Pip. 154, 17–28 (2017). https://doi.org/10.1016/j.ijpvp.2017.06.005

Tesař, K., Jäger, A.: Electron backscatter diffraction analysis of the crack development induced by uniaxial tension in commercially pure titanium. Mater. Sci. Eng. A 616, 155–160 (2014). https://doi.org/10.1016/j.msea.2014.08.028

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kulkarni, O., Kakandikar, G. Novel product design of tool for investigating formability with microstructural study of bio-material titanium grade-II thin foils. Int J Interact Des Manuf 17, 2765–2775 (2023). https://doi.org/10.1007/s12008-022-00903-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00903-3