Abstract

A simple, rapid, and economic method of enzyme immobilization was developed for phospholipase Lecitase® ultra (LU) via interfacial adsorption. The effect of nature of the polystyrene supports and the kinetic behavior and stability of immobilized lecitase® ultra (IM-LU) were evaluated. Six macroporous resins (AB-8, X-5, DA-201, NKA-9, D101, D4006) and two anion resins (D318 and D201) were studied as the supports. DA-201 resin was selected because of its best immobilization effect for LU. Immobilization conditions were investigated, including immobilization time, pH, and enzyme concentration. IM-LU with a lipase activity of 1,652.4 ± 8.6 U/g was obtained. The adsorption process was modeled by Langmuir and Freundlich equations, and the experimental data were better fit for the former one. The kinetic constant (K m) values were found to be 192.7 ± 2.2 mM for the free LU and 249.3 ± 5.4 mM for the IM-LU, respectively. The V max value of free LU (169.5 ± 4.3 mM/min) was higher than that of the IM-LU (53.8 ± 1.5 mM/min). Combined strategies of scanning electron micrograph, thermogravimetric analysis, and Fourier transform infrared (FTIR) spectroscopy were employed to characterize the IM-LU. FTIR spectroscopy showed that the secondary conformation of the enzyme had changed after immobilization, through which a decrease of α-helix content and an increase of β-sheet content were observed. The IM-LU possessed an improved thermal stability as well as metal ionic tolerance when compared with its free form. The reusability of IM-LU was also evaluated through catalyzing esterification reaction between oleic acid and glycerol. It exhibited approximately 70 % of relative esterification efficiency after six successive cycles. This immobilized enzyme on hydrophobic support may well be used for the synthesis of structural lipids in lipid area.

Similar content being viewed by others

Abbreviations

- LU:

-

Lecitase® ultra

- IM-LU:

-

Immobilized Lecitase® ultra

References

Bojsen, K., Svendsen, A., Fuglsang, C. C., Patear, S., Borch, K., Vind, J., et al.. (2000). Novozymes A/S, Denmark. PCT International Application WO2000/32758.

Fernandez-Lorente, G., Filice, M., Terreni, M., Guisan, J. M., Fernandez-Lafuente, R., & Palomo, J. M. (2008). Lecitase® ultra as regioselective biocatalyst in the hydrolysis of fully protected carbohydrates strong modulation by using different immobilization protocols. Journal of Molecular Catalysis B: Enzymatic, 51, 110–117.

Sheelu, G., Kavitha, G., & Fadnavis, N. W. (2008). Efficient immobilization of lecitase in gelatin hydrogel and degumming of rice bran oil using a spinning basket reactor. Journal of the American Oil Chemists’ Society, 85, 739–748.

Yang, B., Wang, Y. H., & Yang, J. G. (2006). Optimization of enzymatic degumming process for rapeseed oil. Journal of the American Oil Chemists’ Society, 83, 653–658.

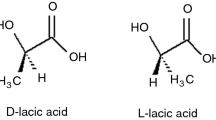

Mishra, M. K., Kumaraguru, T., Sheelu, G., & Fadnavis, N. W. (2009). Lipase activity of Lecitase® Ultra: characterization and applications in enantioselective reactions. Tetrahedron: Asymmetry, 20, 2854–2860.

Wang, Y., Zhao, M., Song, K., Wang, L., Tang, S., & William, W. R. (2010). Partial hydrolysis of soybean oil by phospholipase A1 (Lecitase Ultra). Food Chemistry, 121, 1066–1072.

Liu, N., Wang, Y., Zhao, Q., Zhang, Q., & Zhao, M. (2011). Fast synthesis of 1,3-DAG by Lecitase® Ultra-catalyzed esterification in solvent-free system. European Journal of Lipid Science and Technology, 113, 973–979.

Iyer, P. V., & Ananthanarayan, L. (2008). Enzyme stability and stabilization—aqueous and non-aqueous environment. Process Biochemistry, 43, 1019–1032.

Fernandez-Lorente, G., Palomo, J. M., Guisan, J. M., & Fernandez-Lafuente, R. (2007). Effect of the immobilization protocol in the activity, stability, and enantioselectivity of Lecitase® Ultra. Journal of Molecular Catalysis B: Enzymatic, 47, 99–104.

Cabrera, Z., Fernandez-Lorente, G., Palomo, J. M., Guisan, J. M., & Fernandez-Lafuente, R. (2008). Asymmetric hydrolysis of dimethyl 3-phenylglutarate catalyzed by Lecitase Ultra®: effect of the immobilization protocol on its catalytic properties. Enzyme and Microbial Technology, 43, 531–536.

Garcia-Galan, C., Berenguer-Murcia, A., Fernandez-Lafuente, R., & Rodrigues, R. C. (2011). Potential of different enzyme immobilization strategies to improve enzyme performance. Advanced Synthesis and Catalysis, 353, 2885–2904.

Mateo, C., Palomo, J. M., Fernandez-Lorente, G., Guisan, J. M., & Fernandez-Lafuente, R. (2007). Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme and Microbial Technology, 40, 1451–1463.

Hernandez, K., Garcia-Galan, C., & Fernandez-Lafuente, R. (2011). Simple and efficient immobilization of lipase B from Candida antarctica on porous styrene–divinylbenzene beads. Enzyme and Microbial Technology, 49, 72–78.

Liu, T., Liu, Y., Wang, X., Li, Q., Wang, J., & Yan, Y. (2011). Improving catalytic performance of Burkholderia cepacia lipase immobilized on macroporous resin NKA. Journal of Molecular Catalysis B: Enzymatic, 71, 45–50.

Shi, Z., & Shi, R. (2005). The application of resin for adsorption and separation in medical industry. Beijing: Chemical Industry.

Cheirsilp, B., Jeamjounkhaw, P., & H-Kittikun, A. (2009). Optimizing an alginate immobilized lipase for monoacylglycerol production by the glycerolysis reaction. Journal of Molecular Catalysis B: Enzymatic, 59, 206–211.

Byler, D. M., & Susi, H. (1986). Examination of the secondary structure of proteins by deconvolved FTIR spectra. Biopolymers, 25, 469–487.

Gao, Y., Tan, T. W., Nie, K. L., & Wang, F. (2006). Immobilization of lipase on macroporous resin and its application in synthesis of biodiesel in low aqueous media. Chinese Journal of Biotechnology, 22, 114–118.

Rodrigues, R. C., & Fernandez-Lafuente, R. (2010). Lipase from Rhizomucor miehei as a biocatalyst in fats and oils modification. Journal of Molecular Catalysis B: Enzymatic, 66, 15–32.

Fernandez-Lorente, G., Palomo, J. M., Cabrera, Z., Guisan, J. M., & Fernandez-Lafuente, R. (2007). Specificity enhancement towards hydrophobic substrates by immobilization of lipases by interfacial activation on hydrophobic supports. Enzyme and Microbial Technology, 41, 565–569.

Wilson, L., Palomo, J. M., Fernandez-Lorente, G., Illanes, A., Guisan, J. M., & Fernandez-Lafuente, R. (2006). Effect of lipase-lipase interactions in the activity, stability and specificity of a lipase from Alcaligenes sp. Enzyme and Microbial Technology, 39, 259–264.

Al-Duri, B., & Yong, Y. P. (1997). Characterisation of the equilibrium behaviour of lipase PS (from Pseudomonas) and lipolase 100L (from Humicola) onto Accurel EP100. Journal of Molecular Catalysis B: Enzymatic, 3, 177–188.

Hoshino, K., Taniguchi, M., Katagiri, M., & Fujii, M. (1992). Properties of amylase immobilized on a new reversibly soluble–insoluble polymer and its application to repeated hydrolysis of soluble starch. Journal of Chemical Engineering of Japan, 25, 569–574.

Serefoglou, E., Litina, K., Gournis, D., Kalogeris, E., Tzialla, A. A., Pavlidis, I. V., et al. (2000). Smectite clays as solid supports for immobilization of glucosidase: synthesis, characterization, and biochemical properties. Chemistry of Materials, 28, 4106–4115.

Kharrat, N., Ali, Y. B., Marzouk, S., Gargouri, Y., & Karra-Chaabouni, M. (2011). Immobilization of Rhizopus oryzae lipase on silica aerogels by adsorption: comparison with the free enzyme. Process Biochemistry, 46, 1083–1089.

Peng, R., Lin, J., & Wei, D. (2010). Purification and characterization of an organic solvent-tolerant lipase from Pseudomonas aeruginosa CS-2. Applied Biochemistry and Biotechnology, 162, 733–743.

Rahman, R. N. Z. R. A., Bahrum, S. N., Salleh, A. B., & Basri, M. (2006). S5 lipase: an organic solvent tolerant enzyme. Journal of Microbiology, 44, 583–590.

Brady, D., & Jordaan, J. (2009). Advances in enzyme immobilisation. Biotechnology Letters, 31, 1639–1650.

Acknowledgments

The financial support from the National Natural Science Foundation of China under grant 31000793, the Ministry of Science and Technology of People’s Republic of China under grant 2011BAD02B04, and the Science and Technology Council of Guangdong under grants 2009A020700003 and 2009B080701063 are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, N., Fu, M., Wang, Y. et al. Immobilization of Lecitase® Ultra onto a Novel Polystyrene DA-201 Resin: Characterization and Biochemical Properties. Appl Biochem Biotechnol 168, 1108–1120 (2012). https://doi.org/10.1007/s12010-012-9845-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9845-y