Abstract

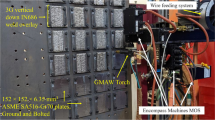

Ultrasonic-assisted metal inert gas (U-MIG) welding experiments were performed to analyze the effect of Cu addition on the microstructure and mechanical properties of galvanized steel sheet welds, and first-principles calculations were undertaken to predict the effect of Cu on the mechanical properties of α-Fe based structures. As shown by scanning electron microscopy analysis, Cu is conducive to the refinement and uniformity of the microstructure in the weld zone. Energy-dispersive spectrometry data indicated the presence of Cu in the welds after welding with Cu powder. The elastic moduli of the welds without and with Cu powder, obtained from nanoindentation tests, were (217.66 ± 5.11) GPa and (223.13 ± 9.12) GPa, respectively, which were close to the calculated results. The mechanical properties of the crystal structures of α-Fe and α-Fe1.9Cu0.1 were calculated using Materials Studio software. Both the experimental and calculated results showed that Cu doping reduced the bulk modulus of the weld but increased its shear modulus.

Similar content being viewed by others

References

YU K C, LI J, LIU X, et al. Microstructure of hot-dip galvanized Zn-Al-Mg alloy coating [J]. Journal of Shanghai Jiao Tong University (Science), 2012, 17(6): 663–667.

MA G H, LI J, HE Y S, et al. Weld geometry monitoring for metal inert gas welding process with galvanized steel plates using Bayesian network [J]. Journal of Shanghai Jiao Tong University (Science), 2021, 26(2): 239–244.

LIN H C, HSU C A, LEE C S, et al. Effects of zinc layer thickness on resistance spot welding of galvanized mild steel [J]. Journal of Materials Processing Technology, 2018, 251: 205–213.

CHEN M J, HUANG J K, HE C C, et al. Thermodynamic analysis of the formation of Fe-Al-Zn intermetallic compounds in Al/galvanized steel interface [J]. Acta Metallurgica Sinica, 2016, 52(1): 113–119 (in Chinese).

MENG X H, LI M X, WU L X, et al. Analysis and countermeasure of defects in welding automobile galvanized steel sheet [J]. Foundry Technology, 2018, 39(3): 625–627 (in Chinese).

ZHOU D W, LIU Y L, LI N N, et al. Effect of Sn-5%Zr powder addition on microstructure and mechanical property of steel/Al laser welding [J]. Chinese Journal of Lasers, 2015, 42(5): 95–103 (in Chinese).

YANG J, ZHANG P F, ZHOU Y F, et al. Mechanical properties of the hardfacing alloys with different La2O3 additives and the mechanism analysis by first-principles calculations [J]. Materials Science and Engineering A, 2014, 591: 82–89.

CHEN L S, HU B J, XU J H, et al. Cu partitioning behavior and its effect on microstructure and mechanical properties of 0.12C-1.33Mn-0.55Cu Q&P steel [J]. Journal of Wuhan University of Technology (Materials Science), 2017, 32(5): 1179–1185.

RAMER N J, RAPPE A M. Virtual-crystal approximation that works: Locating a compositional phase boundary in Pb(Zr1−xTix)O3 [J]. Physical Review B, 2000, 62(2): R743–R746.

SOUVATZIS P, KATSNELSON M I, SIMAK S, et al. First-principles prediction of superplastic transition-metal alloys [J]. Physical Review B, 2004, 70: 012201.

ZHANG F C, ZHANG Z Y, ZHANG W H, et al. Electronic structure of PbxSr1−xTiO3 [J]. Acta Physico-Chimica Sinica, 2009, 25(1): 61–66 (in Chinese).

SEGALL M D, LINDAN P J D, PROBERT M J, et al. First-principles simulation: Ideas, illustrations and the CASTEP code [J]. Journal of Physics: Condensde Matter, 2002, 14(11): 2717–2744.

LI R J, CEN W F, YANG Y Y, et al. First principle calculation of electromagnetic mechanism for Fe2Si bulk material [J]. Journal of Wuhan University of Technology (Materials Science), 2019, 34(1): 64–68.

PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple [J]. Physical Review Letters, 1996, 77(18): 3865–3868.

HOU Z F. Elastic properties and electronic structures of antiperovskite-type InNCo3 and InNNi3 [J]. Solid State Communications, 2010, 150(39/40): 1874–1879.

ASSAEL M J, CHATZIMICHAILIDIS A, ANTONIADIS K D, et al. Reference correlations for the thermal conductivity of liquid copper, gallium, indium, iron, lead, nickel and tin [J]. High Temperatures-High Pressures, 2017, 46(6): 391–416.

HAJITABAR A, NAFFAKH-MOOSAVY H. Effect of electron beam welding current variations on the microstructure and mechanical properties of Nb-1Zr advanced alloy [J]. Vacuum, 2018, 150: 196–202.

MIAO Y G, CHEN G Y, ZHANG P, et al. Comparative study of bypass-current MIG welded-brazed aluminum/galvanized steel and aluminum/stainless steel [J]. Acta Metallurgica Sinica (English Letters), 2017, 30(8): 721–730.

STEPANOVA N, ZIMOGLIADOVA T, OGNEV A, et al. Effect of copper on the structure and antifriction properties of cast hypoeutectoid steel [J]. IOP Conference Series: Materials Science and Engineering, 2017, 286: 012024.

GENG S N, JIANG P, SHAO X Y, et al. Identification of nucleation mechanism in laser welds of aluminum alloy [J]. Applied Physics A, 2019, 125: 396.

ZHANG L F, XIONG Y, ZHANG Y, et al. Microstructure of high manganese steel by laser shock processing [J]. Chinese Journal of Lasers, 2011, 38(6): 226–229 (in Chinese).

DUAN Y H, HUANG B, SUN Y, et al. Stability, elastic properties and electronic structures of the stable Zr-Al intermetallic compounds: A first-principles investigation [J]. Journal of Alloys and Compounds, 2014, 590: 50–60.

KANDASKALOV D, MAUGIS P. A first-principle study of the structural, elastic, lattice dynamical and thermodynamic properties of α″-Fe16C2 and α″-Fe16N2 phases [J]. Computational Materials Science, 2017, 128: 278–286.

CONNÉTABLE D, MAUGIS P. First principle calculations of the κ-Fe3AlC perovskite and iron-aluminium intermetallics [J]. Intermetallics, 2008, 16(3): 345–352.

PUGH S F. XCII. relations between the elastic moduli and the plastic properties of polycrystalline pure metals [J]. Philosophical Magazine, 1954, 45(367): 823–843.

PETTIFOR D G. Theoretical predictions of structure and related properties of intermetallics [J]. Materials Science and Technology, 1992, 8(4): 345–349.

DJEMIA P, BENHAMIDA M, BOUAMAMA K, et al. Structural and elastic properties of ternary metal nitrides TixTa1−xN alloys: First-principles calculations versus experiments [J]. Surface and Coatings Technology, 2013, 215: 199–208.

HUANG Z C, FENG J, PAN W. First-principles calculations of mechanical and thermodynamic properties of YAlO3 [J]. Computational Materials Science, 2011, 50(10): 3056–3062.

LIU Y Z, JIANG Y H, FENG J, et al. Elasticity, electronic properties and hardness of MoC investigated by first principles calculations [J]. Physica B: Condensed Matter, 2013, 419: 45–50.

ZHOU M, GAO X, CHENG Y, et al. Structural, electronic, and elastic properties of CuFeS2: First-principles study [J]. Applied Physics A, 2015, 118: 1145–1152.

ZHU H Y, SHI L W, LI S Q, et al. Effects of biaxial strains on electronic and elastic properties of hexagonal XSi2 (X = Cr, Mo, W) from first-principles [J]. Solid State Communications, 2018, 270: 99–106.

ZHANG L, BARRETT R, CLOETENS P, et al. Anisotropic elasticity of silicon and its application to the modelling of X-ray optics [J]. Journal of Synchrotron Radiation, 2014, 21(3): 507–517.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51665037), the Open Fund of the Key Laboratory of Lightweight and High Strength Structural Materials of Jiangxi Province (No. 20171BCD40003), and the Open Fund of Key Laboratory of Nondestructive Testing Ministry of Education, Nanchang Hangkong University of China (No. EW201980090)

Rights and permissions

About this article

Cite this article

Yu, X., Ye, J., Wu, C. et al. Effect of Cu Addition on the Microstructure and Mechanical Properties of U-MIG Welds on Galvanized Steel Sheets. J. Shanghai Jiaotong Univ. (Sci.) 26, 757–764 (2021). https://doi.org/10.1007/s12204-021-2328-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2328-y